332312A - E4-5 Meter-Mix Dispense System, Operation ... - Graco Inc.

332312A - E4-5 Meter-Mix Dispense System, Operation ... - Graco Inc.

332312A - E4-5 Meter-Mix Dispense System, Operation ... - Graco Inc.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

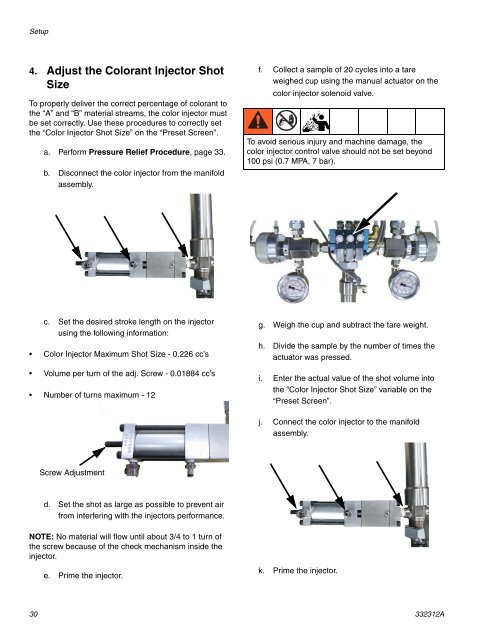

Setup4. Adjust the Colorant Injector ShotSizeTo properly deliver the correct percentage of colorant tothe “A” and “B” material streams, the color injector mustbe set correctly. Use these procedures to correctly setthe “Color Injector Shot Size” on the “Preset Screen”.a. Perform Pressure Relief Procedure, page 33.b. Disconnect the color injector from the manifoldassembly.f. Collect a sample of 20 cycles into a tareweighed cup using the manual actuator on thecolor injector solenoid valve.To avoid serious injury and machine damage, thecolor injector control valve should not be set beyond100 psi (0.7 MPA, 7 bar).c. Set the desired stroke length on the injectorusing the following information:• Color Injector Maximum Shot Size - 0.226 cc’s• Volume per turn of the adj. Screw - 0.01884 cc’s• Number of turns maximum - 12g. Weigh the cup and subtract the tare weight.h. Divide the sample by the number of times theactuator was pressed.i. Enter the actual value of the shot volume intothe “Color Injector Shot Size” variable on the“Preset Screen”.j. Connect the color injector to the manifoldassembly.Screw Adjustmentd. Set the shot as large as possible to prevent airfrom interfering with the injectors performance.NOTE: No material will flow until about 3/4 to 1 turn ofthe screw because of the check mechanism inside theinjector.e. Prime the injector.k. Prime the injector.30 <strong>332312A</strong>