332312A - E4-5 Meter-Mix Dispense System, Operation ... - Graco Inc.

332312A - E4-5 Meter-Mix Dispense System, Operation ... - Graco Inc.

332312A - E4-5 Meter-Mix Dispense System, Operation ... - Graco Inc.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

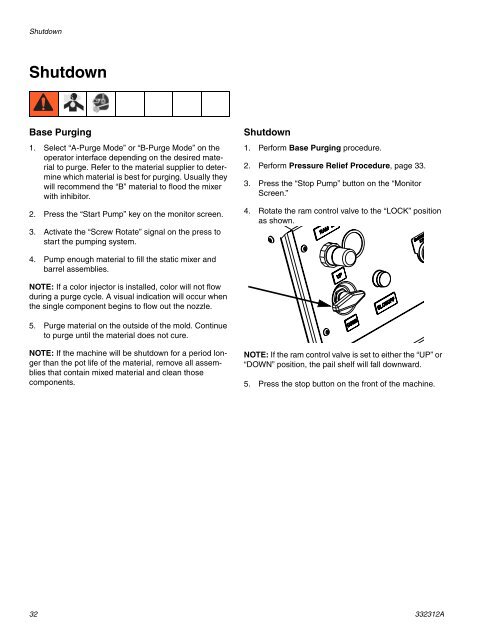

ShutdownShutdownBase Purging1. Select “A-Purge Mode” or “B-Purge Mode” on theoperator interface depending on the desired materialto purge. Refer to the material supplier to determinewhich material is best for purging. Usually theywill recommend the “B” material to flood the mixerwith inhibitor.2. Press the “Start Pump” key on the monitor screen.3. Activate the “Screw Rotate” signal on the press tostart the pumping system.Shutdown1. Perform Base Purging procedure.2. Perform Pressure Relief Procedure, page 33.3. Press the “Stop Pump” button on the “MonitorScreen.”4. Rotate the ram control valve to the “LOCK” positionas shown.4. Pump enough material to fill the static mixer andbarrel assemblies.NOTE: If a color injector is installed, color will not flowduring a purge cycle. A visual indication will occur whenthe single component begins to flow out the nozzle.5. Purge material on the outside of the mold. Continueto purge until the material does not cure.NOTE: If the machine will be shutdown for a period longerthan the pot life of the material, remove all assembliesthat contain mixed material and clean thosecomponents.NOTE: If the ram control valve is set to either the “UP” or“DOWN” position, the pail shelf will fall downward.5. Press the stop button on the front of the machine.32 <strong>332312A</strong>