BIO-<strong>SNG</strong> FEASIBILITY STUDY – ESTABLISHMENT OF A REGIONAL PROJECT6 Economic AssessmentUsing best available information, the economic profile of bio-<strong>SNG</strong> projects is considered. Evaluation ofprocess economics is critically dependent on input assumptions. This builds on the technical review,along with a perspective on costs and impact of existing, and proposed incentives. Plant economics forsuch capital intensive processes are dependent on the state of the market, and costs associated with risktransfer for equipment supplied under EPC contract structures. Similarly, the emergent state of thebiomass market supply chain, along with competitive uses, means that biomass fuel resources will bevolatile. Therefore appropriate sensitivity analyses are undertaken. Against these scenarios, the potentialproject returns are evaluated. This review also compares (at a high level) the returns for a gasificationfacility producing power.This analysis assesses the cost of carbon abatement via this route, when compared with alternative directuses of biomass for heat and electricity as well as other carbon abatement approaches.6.1.1 Scale and operational assumptionsTwo representative scales have been assessed; a small, demonstration scale facility requiring ~100,000te pa of feedstock and a larger commercial facility of requiring ~600,000 te pa . These are outlined inTable 6-1. It is assumed that the process operates at a pressure which matches grid injection such thatdownstream compression requirements are limited. Here it is assumed this would be 20bar, so would besuitable for intermediate or high pressure distribution level injection but not NTS without furthercompression. This assumes therefore that the gasifier operates at the appropriate pressure to account forpressure drops in the gas processing train (typically ~20% from gasifier to exit of methanation reactor, iegasification at ~26bar)Whilst the facility does generate electricity recovered from the high grade heat, at the assumed <strong>SNG</strong>efficiency, the heat suitable for power production is assumed to compensate for the parasitic loads,including the ASU load (separation, oxygen compression) and sufficient CO2 compression for lockhopperinert blanket. In the event that an indirect gasification configuration is used, there would be noASU load, although it is likely that the system would operate at low or atmospheric pressure, thereforeimpose syngas compression loads. Therefore it is assumed in either case there is no excess electricity forexport.44

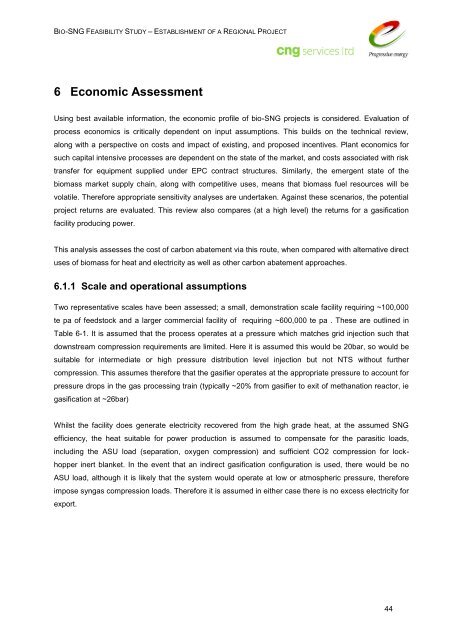

BIO-<strong>SNG</strong> FEASIBILITY STUDY – ESTABLISHMENT OF A REGIONAL PROJECTParameter Small LargeInputEnergy rating (energy per hour) 50MW th (180GJ/hr) 300MWth (1080GJ/hr)Input fuel energy per annum 0.4TWh th (1.3PJ) 2.4 TWh th (8.6PJ)<strong>Bio</strong>mass fuel (pellets, 16GJ/te) pa 81,000 te pa 486,000 te pa<strong>Bio</strong>mass fuel (Woodchip, 13GJ/te) pa 100,000 te pa 600,000 te paSolid Recovered fuel (18GJ/te) te pa 72,000te pa 432,000 te paOperation Load factors (hrs pa) 7200 7200Baseline Efficiency to <strong>SNG</strong> 44 65% 65%Output<strong>Bio</strong>-<strong>SNG</strong> MWth 32.5MWth 195MWth<strong>Bio</strong>-<strong>SNG</strong> GJ/Hr 117 702<strong>Bio</strong>-<strong>SNG</strong> therm/hr 1110 6,650<strong>Bio</strong>-<strong>SNG</strong> Nm 3 /hr 3330 20,000<strong>Bio</strong>-<strong>SNG</strong> energy per annum 0.23 TWh th (0.84PJ) 1.40 TWh th (5.05PJ)Equivalent Households ~15,000 ~100,000Equivalent Passenger Vehicles ~25,000 ~150,000Comparative Electrical facility (no <strong>SNG</strong>) 12MWe (24%efficiency assuminggas engines)Table 6-1 Project scale and output assumptions6.1.2 Investment Cost assumptions90MWe (30% efficientbased on an IGCCconfiguration)As discussed previously, there are currently no commercial scale <strong>Bio</strong>-<strong>SNG</strong> facilities in operation, andthere is only a limited number of biomass gasification facilities which create a syngas of sufficient qualityfor catalytic conversion, with still fewer operating on waste derived fuels. Therefore investment costassumptions are estimates, however these are sufficient to enable an understanding of the economics ofthe process, given that even estimates from suppliers are only +/-30% after a formal engineering study.The following investment costs are dominated by the capital costs of the materials handling, gasifier, gasprocessing, methanation and conditioning for injection. The costs also allow for utilities and services,including grid/gas connection and indirect costs (design, development, constructionmanagement/commissioning and contingency).The cost of performance guarantees being provided by an EPC cannot be readily ascertained at thisstage, as they will depend on both the detailed requirements of the funder, and also the EPC‟s appetitefor the sector combined with the ability to cascade the guarantees down the supply chain. Suchguarantees would form part of detail project negotiations, and are not included here. Final out-turn costsare a function of the final design, the financing route and cost of risk transfer as well as general economicissues including exchange rates, appetite for an EPC contractor to undertake the work and competitionfor supply in a sector with an immature supply chain. The cost estimates below are developed using thea range of data sources:44 Based on Pellets or SRF. Where the fuel has higher moisture content (eg woodchips, modelled here at 25%), thetotal efficiency can be higher when low grade waste heat is utilised to pre-dry the fuel prior to gasification. 65% isconsidered a credible conversion efficiency using existing gasifier and methanation combinations.45