FOR AUTO RTM

1VeKpGy

1VeKpGy

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

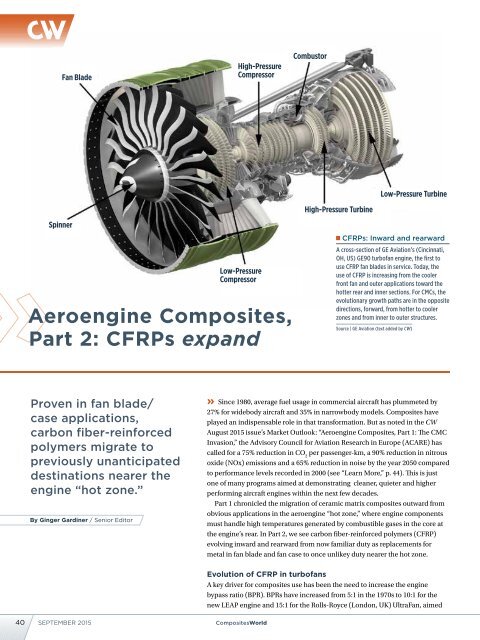

Fan Blade<br />

High-Pressure<br />

Compressor<br />

Combustor<br />

Low-Pressure Turbine<br />

Spinner<br />

Low-Pressure<br />

Compressor<br />

Aeroengine Composites,<br />

Part 2: CFRPs expand<br />

High-Pressure Turbine<br />

CFRPs: Inward and rearward<br />

A cross-section of GE Aviation’s (Cincinnati,<br />

OH, US) GE90 turbofan engine, the first to<br />

use CFRP fan blades in service. Today, the<br />

use of CFRP is increasing from the cooler<br />

front fan and outer applications toward the<br />

hotter rear and inner sections. For CMCs, the<br />

evolutionary growth paths are in the opposite<br />

directions, forward, from hotter to cooler<br />

zones and from inner to outer structures.<br />

Source | GE Aviation (text added by CW}<br />

Proven in fan blade/<br />

case applications,<br />

carbon fiber-reinforced<br />

polymers migrate to<br />

previously unanticipated<br />

destinations nearer the<br />

engine “hot zone.”<br />

By Ginger Gardiner / Senior Editor<br />

» Since 1980, average fuel usage in commercial aircraft has plummeted by<br />

27% for widebody aircraft and 35% in narrowbody models. Composites have<br />

played an indispensable role in that transformation. But as noted in the CW<br />

August 2015 issue’s Market Outlook: “Aeroengine Composites, Part 1: The CMC<br />

Invasion,” the Advisory Council for Aviation Research in Europe (ACARE) has<br />

called for a 75% reduction in CO 2<br />

per passenger-km, a 90% reduction in nitrous<br />

oxide (NOx) emissions and a 65% reduction in noise by the year 2050 compared<br />

to performance levels recorded in 2000 (see “Learn More,” p. 44). This is just<br />

one of many programs aimed at demonstrating cleaner, quieter and higher<br />

performing aircraft engines within the next few decades.<br />

Part 1 chronicled the migration of ceramic matrix composites outward from<br />

obvious applications in the aeroengine “hot zone,” where engine components<br />

must handle high temperatures generated by combustible gases in the core at<br />

the engine’s rear. In Part 2, we see carbon fiber-reinforced polymers (CFRP)<br />

evolving inward and rearward from now familiar duty as replacements for<br />

metal in fan blade and fan case to once unlikey duty nearer the hot zone.<br />

Evolution of CFRP in turbofans<br />

A key driver for composites use has been the need to increase the engine<br />

bypass ratio (BPR). BPRs have increased from 5:1 in the 1970s to 10:1 for the<br />

new LEAP engine and 15:1 for the Rolls-Royce (London, UK) UltraFan, aimed<br />

40 SEPTEMBER 2015<br />

CompositesWorld