FOR AUTO RTM

1VeKpGy

1VeKpGy

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Hurricane-Durable Composite NEWS Docks<br />

to sustain Category 3 forces — 205-241 kph winds and 2.74-<br />

3.66m of sea storm surge — but also to provide shelter for emergency<br />

response crews and dozens of storm refugees. JFRD had<br />

purchased a new 22m fireboat boat, Marine One, which would be<br />

permanently moored at Station 40 on a new 22m by 2.4m floating<br />

dock. Additionally, a 67m long by 1.8m wide fixed portion of the<br />

new dock structure needed permanent lifts for a 9.14m fireboat<br />

and two same-sized Port Authority security boats.<br />

“The first bids to<br />

build the dock with<br />

reinforced concrete Composites ... were able to<br />

were rejected<br />

meet all the technical and<br />

because they<br />

grant-funding requirements,<br />

were too expensive,”<br />

explains<br />

including budget and timeline.<br />

Register<br />

Marine president<br />

George Register. With all bids 50% over the budget, and no<br />

viable alternatives, the city believed it would have to forfeit the<br />

grant money and abandon plans for the new dock construction.<br />

But then Register found out about the project and met with city<br />

engineers. “We reoriented the program to use composites,” he<br />

says, “and were able to meet all of the technical and grant-funding<br />

requirements, including budget and timeline.”<br />

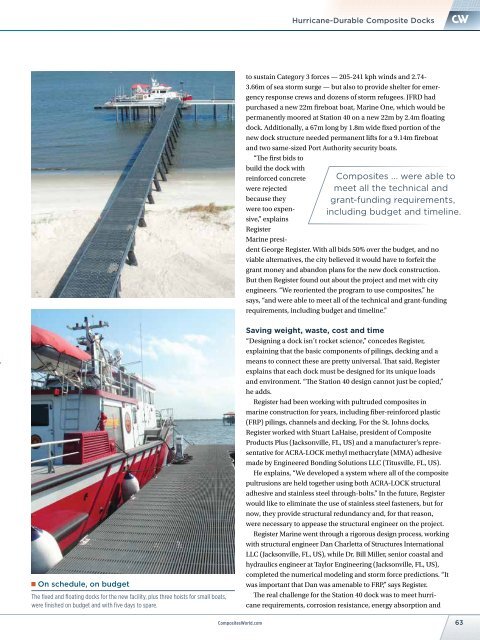

On schedule, on budget<br />

The fixed and floating docks for the new facility, plus three hoists for small boats,<br />

were finished on budget and with five days to spare.<br />

Saving weight, waste, cost and time<br />

“Designing a dock isn’t rocket science,” concedes Register,<br />

explaining that the basic components of pilings, decking and a<br />

means to connect these are pretty universal. That said, Register<br />

explains that each dock must be designed for its unique loads<br />

and environment. “The Station 40 design cannot just be copied,”<br />

he adds.<br />

Register had been working with pultruded composites in<br />

marine construction for years, including fiber-reinforced plastic<br />

(FRP) pilings, channels and decking. For the St. Johns docks,<br />

Register worked with Stuart LaHaise, president of Composite<br />

Products Plus (Jacksonville, FL, US) and a manufacturer’s representative<br />

for ACRA-LOCK methyl methacrylate (MMA) adhesive<br />

made by Engineered Bonding Solutions LLC (Titusville, FL, US).<br />

He explains, “We developed a system where all of the composite<br />

pultrusions are held together using both ACRA-LOCK structural<br />

adhesive and stainless steel through-bolts.” In the future, Register<br />

would like to eliminate the use of stainless steel fasteners, but for<br />

now, they provide structural redundancy and, for that reason,<br />

were necessary to appease the structural engineer on the project.<br />

Register Marine went through a rigorous design process, working<br />

with structural engineer Dan Charletta of Structures International<br />

LLC (Jacksonville, FL, US), while Dr. Bill Miller, senior coastal and<br />

hydraulics engineer at Taylor Engineering (Jacksonville, FL, US),<br />

completed the numerical modeling and storm force predictions. “It<br />

was important that Dan was amenable to FRP,” says Register.<br />

The real challenge for the Station 40 dock was to meet hurricane<br />

requirements, corrosion resistance, energy absorption and<br />

CompositesWorld.com 63