FOR AUTO RTM

1VeKpGy

1VeKpGy

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

INSIDE MANUFACTURING<br />

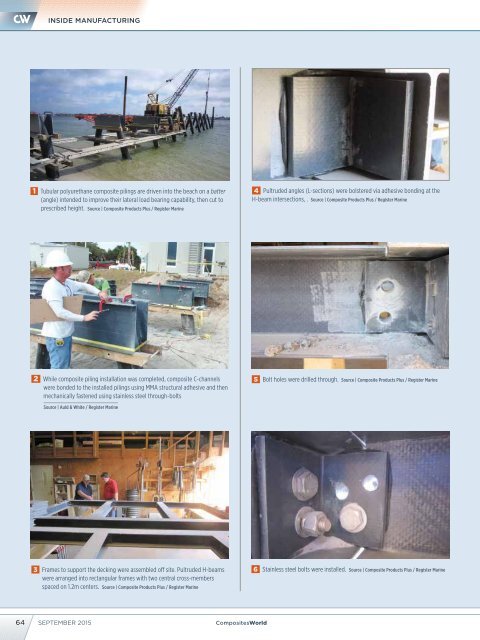

1 Tubular polyurethane composite pilings are driven into the beach on a batter<br />

(angle) intended to improve their lateral load bearing capability, then cut to<br />

prescribed height. Source | Composite Products Plus / Register Marine<br />

4 Pultruded angles (L-sections) were bolstered via adhesive bonding at the<br />

H-beam intersections, . Source | Composite Products Plus / Register Marine<br />

2 While composite piling installation was completed, composite C-channels<br />

were bonded to the installed pilings using MMA structural adhesive and then<br />

mechanically fastened using stainless steel through-bolts<br />

5 Bolt holes were drilled through. Source | Composite Products Plus / Register Marine<br />

Source | Auld & White / Register Marine<br />

3 Frames to support the decking were assembled off site. Pultruded H-beams<br />

were arranged into rectangular frames with two central cross-members<br />

spaced on 1.2m centers. Source | Composite Products Plus / Register Marine<br />

6 Stainless steel bolts were installed. Source | Composite Products Plus / Register Marine<br />

64 SEPTEMBER 2015<br />

CompositesWorld