www.joskin.com

Spreading & injection equipment programme - joskin

Spreading & injection equipment programme - joskin

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

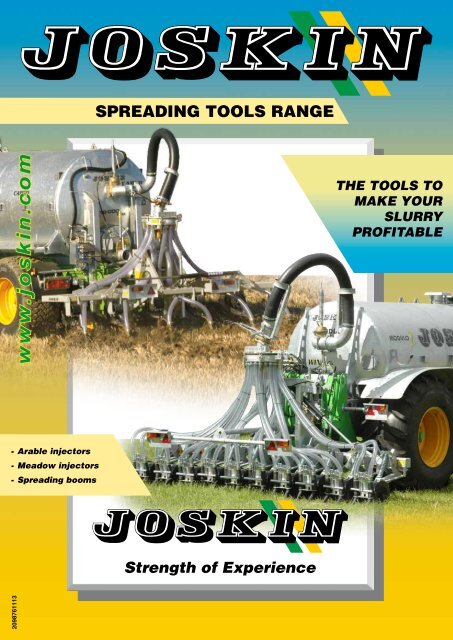

Spreading tools range<br />

<strong>www</strong>.<strong>joskin</strong>.<strong>com</strong><br />

The tools to<br />

make your<br />

slurry<br />

profitable<br />

- Arable injectors<br />

- Meadow injectors<br />

- Spreading booms<br />

Strength of Experience<br />

2098761113

General points<br />

When the optimal use of farm manure be<strong>com</strong>es a true source of profitability, it is important to choose the<br />

appropriate material. The current spreading methods substantially reduce the loss of volatile fertilizers in<br />

the slurry. Therefore, the spread slurry remains very rich and allows you to spare chemical fertilizers.<br />

The JOSKIN ‘‘Spreading tools’’ programme offers a solution for the injection in meadows - with discs,<br />

trailing shoes or shares - the injection in arable grounds - with rigid or flexible tines - or for the boom spreading<br />

- line, multi-nozzle, dual-nozzle. The working widths vary, according to the models, from 2.80 meters<br />

to 24 meters.<br />

The use of an injector means, more and more, a profitable investment, even in the short-term. Moreover,<br />

the whole range of JOSKIN slurry tankers is <strong>com</strong>patible with a possible spreading tool.<br />

Manufacture of the rear implements<br />

Computer-aided design<br />

The conception of spreading tools is entirely <strong>com</strong>puterized. The<br />

three-dimensional drawing of the <strong>com</strong>ponents is carried out by<br />

the Pro-Engineer software. With this software, the JOSKIN<br />

development team can view the part drawings from all angles before<br />

starting the production.<br />

From the very beginning of the project, the design is linked to<br />

the SAP global management programme: the designers directly<br />

integrate the new parts lists to the central configurator. As a result,<br />

the new concept immediately <strong>com</strong>es within the continuous<br />

development process.<br />

This integrated architecture allows to standardize the production<br />

as much as possible and to rationalize the <strong>com</strong>ponents, leading<br />

to a higher manufacturing precision and production flexibility.<br />

Mounting the spreading tools<br />

The injectors and booms are mounted individually from a stationary<br />

place. First, the different parts of the injection or spreading<br />

elements as well as<br />

the macerator(s) are<br />

assembled. These elements<br />

are then mounted<br />

on the chassis of<br />

the machine.<br />

After this, the finishing<br />

is carried out before<br />

testing the tool. Once<br />

mounted on the slurry<br />

tanker, all the rear implements are tested by a specialized team.<br />

Manufacturing the chassis of spreading tools<br />

The manufacturing stage is in accordance with the JOSKIN<br />

production philosophy. The automated machine tools stand for an<br />

unmatched precision. The digital cutting lasers and saws ensure<br />

the cutting of profiles and steel sheets. The turning machines,<br />

machining centre, folding presses, to name but a few, are entirely<br />

automated machines preventing any mistake.<br />

The unbroken welding is carried out by robots. They ensure regular<br />

weld seams without splashing.<br />

The longevity of the JOSKIN material is increased by the<br />

galvanization with which it is coated.<br />

Completely individualized parts book<br />

The most obvious expression of the <strong>com</strong>puter-aided<br />

management of the integrated<br />

JOSKIN production is the individualized<br />

parts book JOSKIN delivers with<br />

each spreading tool. This book includes<br />

the drawings and references of the <strong>com</strong>ponents<br />

mounted on the vehicle, with the<br />

exclusion of any other part. In this way,<br />

many mistakes can be avoided when ordering<br />

spare parts - even years later.<br />

-2-

Spreading tools<br />

Type Name Illustration Specifications Page<br />

• Arable injector with 2 rows of rigid tines<br />

Terrasoc • 24 wide duckfoot shares with 40 cm intervals 12<br />

• Re<strong>com</strong>mended working depth: 10 to 12 cm<br />

Arable injectors<br />

• Arable injector with 2 rows of flexible tines<br />

Terraflex/2<br />

• 30 or 40 cm intervals<br />

• Straight reversible shares of 6.5 cm<br />

13<br />

• Re<strong>com</strong>mended working depth: 12 to 15 cm<br />

• Type Terraflex/2 with 3 rows of tines instead of 2<br />

Terraflex/3<br />

• 30 or 40 cm intervals<br />

• Wider model available<br />

13<br />

• Designed to avoid blockages as much as possible<br />

Meadow injectors<br />

• Injector with trailing shoes<br />

• Works thanks to its own weight<br />

Multi-action • Working depth: 0 to 3 cm according to the type of soil 16<br />

• Multifunctional on stubble-fields, meadows,<br />

growing crops<br />

• Disc injector, large diameter: 406 mm<br />

• Hydraulic block with constant pressure system to<br />

Solodisc<br />

adjust the working depth<br />

• Working depth: 1 to 6 cm (according to the type of soil)<br />

18<br />

• Multifunctional on meadows, growing crops, stubblefields<br />

• Dual-nozzle spreading boom<br />

TWINJET<br />

• Traditional spreading (sheet spreading)<br />

over a large width<br />

20<br />

• Direct feeding : without Scalper © macerator<br />

Spreading booms<br />

• Multi-nozzle spreading boom<br />

MULTITWIST • Spreading close to the ground with even distribution 21<br />

• Direct feeding : without Scalper © macerator<br />

• Line spreading boom<br />

Penditwist<br />

• Laying slurry in a line on the ground<br />

• Numerous applications (meadows, growing crops, ...)<br />

22<br />

• Pipe intervals of 25 or 30 cm<br />

- 3 -<br />

-3-

an appropriate structure<br />

Structure of the vehicles<br />

Provided the adequate (pre-)equipment is available, all JOSKIN slurry tankers can be equipped with a rear spreading tool. Either for<br />

self-supporting vehicles or for vehicles with chassis, the JOSKIN ‘‘Slurry tankers’’ programme offers various adaptation possibilities.<br />

Moreover, there is a vast number of options making the work with a spreading tool easier, these are explained in the following pages.<br />

Universal chassis<br />

Self-supporting vehicles<br />

The JOSKIN KOMFORT2, COBRA, QUADRA, X-TREM<br />

and EUROLINER ranges are equipped with a universal chassis.<br />

This chassis, which is <strong>com</strong>pletely independent from the tank,<br />

offers the following advantages:<br />

For self-supporting vehicles such as the MODULO2, the option ‘‘tank<br />

buttresses’’ is available. This option consists in reinforcing the tank<br />

in such a way that the rear implement weight strains are transfered<br />

on the whole vehicle. Line and multi-nozzle spreading booms as<br />

well as Multi-Action, Solodisc (up to 5.16m) and arable injectors (up<br />

to 11 tines) can be hitched to the buttresses.<br />

• total concentration of the strains on the chassis;<br />

• tank <strong>com</strong>pletely protected from the stress of the rear tool<br />

Besides, thanks to its intrinsic characteristics, the chassis<br />

makes it possible:<br />

• to hitch rear tools with or without linkage;<br />

• to move the running gear in order to modify the load distribution<br />

according to the weight of the rear implement;<br />

• to standardize: because the single-axle chassis is the same as<br />

the double-axle chassis;<br />

• to focus the traction strains of the rear implement on the chassis<br />

(the rear implement does not pull the tank);<br />

• to use all the JOSKIN spreading systems (and other<br />

systems too provided some possible adaptations are made).<br />

Ø 6’’ Communicating gauge<br />

To continuously control the slurry level<br />

and visualize the end of the tank<br />

emptying process<br />

Upper access<br />

Highly re<strong>com</strong>mended to make<br />

the cleaning operations easier<br />

Ø 150mm JOSKIN<br />

pressure relief valve<br />

To make sure the flow is precisely<br />

and regularly adjusted<br />

Whatever the chassis width, it is always possible to fit a linkage<br />

on it. Indeed, the linkages are designed according to the existing<br />

chassis widths, either for traditional widths (1,000 mm for Komfort,<br />

Quadra and Euroliner) or for narrower widths (600 mm for<br />

Cobra).<br />

-4-<br />

Universal chassis<br />

All the strains are focused on it (no<br />

stresses of the rear implement to<br />

the tank)<br />

Adjustable running gear<br />

to balance the vehicle according<br />

to the weight of the rear implements

linkages<br />

Compact tool lifting device<br />

The JOSKIN coupling systems are very <strong>com</strong>pact in order to<br />

limit the side and vertical strains on the whole running gear. Made up<br />

of four points, they ensure a very high stability of the rear implement<br />

while reducing the overhanging<br />

part.<br />

The tankers which are<br />

equipped with a narrow<br />

universal chassis (600<br />

mm) are fitted with a<br />

specific linkage.<br />

The ‘‘Low-Lift’’ linkage does not<br />

take much place at the back<br />

of the tank thanks to its limited<br />

height. Designed for the quick<br />

coupling, this linkage is available<br />

on the KOMFORT, QUADRA,<br />

X-TREM, EUROLINER and<br />

CARGO.<br />

Several options are available on the linkages:<br />

- spring suspension for linkage;<br />

- electric control of the linkage at the back of the tanker making it<br />

easier to hitch the spreading tool;<br />

- connection of an exact scatterer through the linkage.<br />

Even with a rear implement, it is<br />

always possible to spread slurry in<br />

the traditional way. The option ‘‘Exact<br />

scatterer on injector’’ has been designed<br />

for this purpose.<br />

The adjusting key of the upper<br />

tie rods is supplied with all<br />

JOSKIN linkages.<br />

The transport locks as well as<br />

the Walterscheid quick coupling<br />

are also part of the standard<br />

equipment.<br />

Sequential<br />

hydraul.<br />

block<br />

Low-Lift linkage on Vacu-<br />

CARGO.<br />

Manual flow regulating<br />

valve<br />

Linkage on KOMFORT2. Also<br />

available on MODULO2 and<br />

QUADRA<br />

Macerator<br />

Appropriate axles<br />

To support the extra weight<br />

arising from the rear implement<br />

Linkage<br />

8’’ Draining cap<br />

To make the cleaning operations<br />

easier<br />

Narrow linkage on COBRA<br />

chassis (fastened by 4 tapered<br />

shafts to make it a solid<br />

construction).<br />

- 5 -<br />

-5-

Practical and<br />

Level indicator<br />

Upper access<br />

The gauge is made up of transparent perspex (Ø 6’’). This device,<br />

which is also available in kit form to be bolted, can be mounted afterwards<br />

if necessary. In option, a protective grate can be placed<br />

in front of the gauge (advised when using a dorsal boom).<br />

Most spreading tools prevent the access<br />

to the tank at the back. That’s why it is<br />

highly re<strong>com</strong>mended to place an upper<br />

access to the tank.<br />

➋<br />

JOSKIN offers three different types<br />

of upper access:<br />

• Ø 600 mm normal opening<br />

(4 hooks) (1);<br />

• Ø 600 mm quick opening, mounted on a<br />

hinge (2);<br />

• Hydraulic sliding trap (500 x 600 mm) (3).<br />

➊<br />

➌<br />

All types of upper access are standard<br />

fitted with fully galvanized inside<br />

and outside ladders.<br />

The level float gauge is another alternative,<br />

which however gives no<br />

information about the slurry consistency.<br />

JOSKIN pressure<br />

relief valve<br />

A regular pression is essential to spread with accuracy.<br />

-6-<br />

Ecopump<br />

A vacuum pump naturally makes the used<br />

oil flow out with the expelled air. Based on<br />

this principle, the ECOPUMP aims at:<br />

- collecting the oil (environmental concern),<br />

- reducing the noise level (see table below),<br />

- longer lifetime of your vacuum pump,<br />

- a structure with 2 chambers for extra cooling.<br />

Upper chamber containing the<br />

air <strong>com</strong>ing from and going to the<br />

pump<br />

Separate chamber containing<br />

the air from the<br />

pressure relief valve<br />

Exhaust pipe for the overpressure<br />

air<br />

Small pipe collecting the oil from the upper<br />

chamber<br />

Compared noise levels Standard pump ECOPUMP<br />

Suction 93.3 mW 25.7 mW<br />

Discharge 53.7 mW 19.5 mW<br />

In option, and standard with some<br />

pumps and some spreading tools, the<br />

high-capacity pressure relief valve (Ø<br />

150 mm) allows to quickly evacuate the<br />

overpressure and to prevent the pump<br />

from prematurely overheating. Thanks<br />

to this option, it is also possible to adjust<br />

the spreading flow by acting on the overpressure<br />

rate of the tank.<br />

A big adjusting wheel with locknut allows an easy and accurate<br />

adjustment; thanks to this, it is possible to obtain a precise adjustment<br />

of the flow rate when spreading. This device is necessary<br />

for a regular work of the spreading tools.<br />

Draining cap<br />

A draining cap (Ø 8’’), located under the tank, makes the cleaning<br />

operations easier in case an implement is fitted at the back.<br />

Thanks to the sloping position<br />

of the tank and the position<br />

of the cap in the lowest<br />

part of the tank, the draining<br />

cap also acts as a stone trap.<br />

This cap is standard fitted on<br />

all tankers with a pre-equipment<br />

for an injector.

e<strong>com</strong>mended equipment<br />

Electronic flow meter<br />

ISOBUS + flow meter<br />

A perfect measurement for a regular<br />

precision!<br />

The electronic flow meter (Ø<br />

150 mm) ensures an accurate<br />

flow at any time. Whatever the<br />

driving speed, the spreading<br />

remains uniform thanks to the<br />

device adjusting the flow in<br />

proportion to the advancement<br />

speed (DPA).<br />

The working principle is as follows: the flow meter constantly<br />

measures the slurry injection flow while sensors,<br />

located at the wheels, measure the driving speed.<br />

By interpreting these data, a <strong>com</strong>puter will automatically<br />

regulate the slurry flow according to the driving<br />

speed, by way of an electric valve.<br />

Main functions of the electronic flow meter:<br />

• flow regulation<br />

• calculation (partial or total surface, working hours, speed,<br />

distance, output ha/h or l/ha)<br />

• spreading work management (storing the work carried out and<br />

to be carried out)<br />

• alarms (excessive speed)<br />

• allows to use the tractor potential as much as possible with a<br />

guaranteed flow<br />

The Simple Cut chopper is<br />

based on the patented technique<br />

of the SCALPER ® macerators.<br />

Indeed, any foreign<br />

body in the slurry is chopped<br />

by the 3 self-sharpening circular<br />

blades turning against<br />

a contra-rotating blade fitted<br />

with conical openings.<br />

Simple Cut chopper<br />

In this way, slurry is homogeneously distributed in the rear spreading<br />

tool while making sure that the possible foreign bodies do not<br />

prevent the macerator from working properly. The stones and other<br />

foreign bodies are collected in a trap that is easy to reach and has<br />

to be emptied regularly. This operation is made easier by a quick<br />

opening system.<br />

In the mixing phase, slurry also flows through the <strong>com</strong>partment of<br />

the chopper. Indeed, the pipe system of this <strong>com</strong>partment has been<br />

designed to guide the slurry from the tank to the pump, through the<br />

chopper when this one is not working.<br />

The ISOBUS principle is to centralize all the electrohydraulic functions<br />

of your machines in one single control box, called Terminal. This<br />

Terminal is connected to the software integrated into each machine.<br />

Then, once the software is downloaded by the Terminal, this one displays<br />

on its screen all the functions it can operate for the machine.<br />

The tractors fitted with the ISOBUS system will then perfectly be<br />

able to oprate the flow<br />

meter function. The user<br />

will no longer need the<br />

control box that is specific<br />

to the flow meter.<br />

A GPS system is available<br />

in option. It will provide<br />

even more precision<br />

for the spreading.<br />

Do not hesitate to contact us for further information.<br />

The so-called ‘‘umbilical’’ system has an Anglo-Saxon origin and<br />

allows to spread slurry without using a slurry spreader. Yet, it requires<br />

quite a heavy organization in order to feed the implement directly<br />

connected to the tractor: reel, pipes (max. 1500 m), centrifugal<br />

pumps... It is therefore<br />

not possible to spread<br />

too far from the pit.<br />

The Penditwist, Terrasoc,<br />

Terraflex, Solodisc<br />

and Multi-Action tools<br />

may be used according<br />

to this principle. They<br />

can be independently<br />

mounted on our slurry<br />

tankers or on a specific<br />

support to be hitched<br />

to the tractor.<br />

Umbilical system<br />

It is worth noting that this option requires an adaptation of the<br />

spreader beforehand. It is therefore re<strong>com</strong>mended to fit the slurry<br />

tanker with an appropriate pre-equipment in order to mount the<br />

chopper later.<br />

- 7 -<br />

-7-

Slurry distribution<br />

-8-<br />

SCALPER © macerator<br />

A good macerator is essential to make sure the injector<br />

works properly because all kinds of slurry (but<br />

mainly cattle slurry) are full of fibres and foreign<br />

bodies. Now, a blocked opening means an uneven<br />

spreading pattern: then, the user has to<br />

stop working and to clean the machine, which<br />

is quite constraining!<br />

The JOSKIN solution is the patented<br />

system of the macerator with cutting and<br />

self-sharpening discs: the JOSKIN<br />

SCALPER © .<br />

The cutting system of the<br />

SCALPER © is merciless: free<br />

rotating circular blades are<br />

mounted on a rotating blade<br />

head driven by a hydraulic<br />

motor. There is a scissors<br />

effect between the circular<br />

blades and the elliptical arched<br />

and off-centre openings<br />

of the blade head, inevitably<br />

cutting all foreign bodies in<br />

the slurry.<br />

When the blades strike against too hard<br />

obstacles, the rotation direction of the<br />

SCALPER © is reversed by the ‘‘Switch-<br />

Matic’’ system (option) until the obstacle<br />

is chopped.<br />

The JOSKIN macerator is placed<br />

by fitting and clipping. A multi-position<br />

manual valve, fixed at the macerator<br />

inlet, offers a step by step adjustment<br />

of the injector feeding. The precise adjustment<br />

is carried out by means of the<br />

pressure relief valve and the chosen<br />

type of contra-rotating blade.<br />

Model -2, -1, 0 et 1 Model 2 Model 3<br />

Flow: 7 to 20 m³/ha<br />

Flow: 12 to 30 m³/ha<br />

Flow: 25 to 50 m³/ha<br />

The hydraulic circuit is isolated thanks to a cap. A drain makes it<br />

possible to check wether the water seal is faulty.<br />

The JOSKIN SCALPER © macerators are also sold separately<br />

in order to equip existing injectors.<br />

Macerator feeding<br />

The macerator is standard fed through a 6’’ rubber hose and a 6’’<br />

adjusting valve.<br />

Vertical SCALPER © macerator<br />

The working principle of<br />

the vertical macerator,<br />

fitting the Penditwist line<br />

spreading booms, is the<br />

same as for the horizontal<br />

macerator: a rotating<br />

blade head, driven by a<br />

hydraulic motor, supports<br />

eight self-sharpening<br />

circular blades turning<br />

freely against a contrarotating<br />

blade. However,<br />

as the macerator is fitted with openings on both sides, it is equipped<br />

with two cutting systems. The slurry under pressure goes into<br />

the central chamber of the macerator via a 6’’ inlet, before being<br />

taken care of by the blades that cut the foreign bodies and evenly<br />

distribute the slurry between the different openings (20, 26, 30 or<br />

36 openings, according to the models). These are horizontal and<br />

have a diameter of 42 mm. A 6’’ cap, acting as a stone trap, gives<br />

access to the inside of the macerator.<br />

The advantages of this vertical macerator are the small overal dimensions<br />

and limited load losses in the injection pipes (less bends<br />

in the pipes). As a result, slurry is more homogeneously distributed<br />

in the line spreading booms.<br />

Reference<br />

Type<br />

Number of<br />

Macerator<br />

outlets Ø mm Motor Type (cc)<br />

B-model macerator with Ø 48 mm outlets downwards and Ø 6’’ inlet above<br />

J60620121+2 12B 12 420 160<br />

J60620141+2 14B 14 420 160<br />

J60620161+2 16B 16 420 315<br />

J60620201+2 20B 20 490 315<br />

J60620240+2 24B 24 565 315<br />

J60620281+2 28B 28 655 315<br />

J60620320+2 32B 32 730 500<br />

J60620360+2 36B 36 811 500<br />

J60620400+2 40B 40 900 500<br />

BC-model macerator with Ø 60 mm outlets downwards and Ø 6’’ inlet above<br />

J60626142+3 14BC 14 565 160<br />

J60626172+3 17BC 17 565 160<br />

J60626206+3 20BC 20 565 315<br />

J60626246+3 24BC 24 565 315<br />

J60626326+3 32BC 32 730 500<br />

J60626366+3 36BC 36 811 500<br />

J60626406+3 40BC 40 900 500<br />

VR-model vertical macerator with Ø 42 mm horizontal outlets and Ø 120 mm lateral<br />

inlet (2 counterblades per macerator)<br />

J60621203(04)-1 20VR L (R) 20 430 395<br />

J60621263(64)-1 26 VR L (R) 26 430 395<br />

J60621301(02)-1 30 VR L (R) 30 430 395<br />

J60621363(64)-1 36 VR L (R) 36 430 500

Hydraulic controls<br />

Sequential blocks<br />

ISOBUS<br />

For an optimal use of the spreading<br />

tool, the user-friendly and<br />

environmentally acceptable character<br />

of the machine and the protection<br />

of the grass and the material,<br />

an automatic control system<br />

of the hydraulic functions of any<br />

injector is absolutely necessary.<br />

The automated sequence of hydraulic<br />

functions allows the driver<br />

to only care about the lowering or<br />

lifting and the unfolding of the spreading tool.<br />

The sequential block operates all the other functions corresponding<br />

to the working of the spreading tool:<br />

• lifting - lowering the tool (driver);<br />

• lowering speed two times faster in relation to the oil supply<br />

of the tractor (on Polymatic & Instamatic);<br />

• opening of the slurry feeding valve;<br />

• start of the slurry macerator(s);<br />

• control of the automatic reverse of the macerator;<br />

• opening-closing the hydraulic anti-drip pincers on the<br />

Solodisc meadow injectors;<br />

• control of the Cleanmatic © in option on arable injectors;<br />

• automatic adaptation to uneven ground with constant pressure<br />

(Solodisc).<br />

Electrovalves<br />

According to the chosen injector<br />

and sequential block, 2 or 3 hydraulic<br />

functions will be necessary.<br />

If the macerator is operated by<br />

means of an eletrohydraulic box,<br />

a high flow entry block is then indispensable<br />

to increase the output of the hydraulic motor and<br />

prevent load losses and overheating problems.<br />

Eventually, all the hydraulic<br />

functions of<br />

the sequential block<br />

will be operated by<br />

the ISOBUS.<br />

Assuming that all<br />

your functions are<br />

connected to the<br />

electrovalves, the<br />

Terminal of the tractor<br />

will be<strong>com</strong>e your<br />

only control box.<br />

Controlling the injector weight on<br />

the ground<br />

All arable injectors<br />

(Terrasoc, Terraflex2<br />

and Terraflex3) and<br />

meadow injectors<br />

include an option<br />

allowing to lift the<br />

injector in humid<br />

places. This ‘‘Wet<br />

surface kit’’ device is<br />

made up of a valve<br />

allowing to lift the<br />

rear tool when going<br />

from a dry area to a humid one; a load transfer to the tanker<br />

then takes place while the feeding valve and macerator remain<br />

functional.<br />

The hydraulic anti-drip pincers stay open with this system. In the<br />

case of mechanical pincers, it is up to the driver to see if they do<br />

not close the injection pipes when the injector is lifted.<br />

Easymatic Easymatic+ Polymatic Instamatic<br />

Terrasoc standard option option option<br />

Terraflex standard option option option<br />

Multi-action - standard option option<br />

Solodisc - - standard option<br />

Penditwist standard option - -<br />

- 9 -<br />

-9-

Arable injectors<br />

General points<br />

The JOSKIN arable injectors include injectors with rigid tines<br />

(Terrasoc) and injectors with flexible tines (Terraflex/2 and Terraflex/3).<br />

Structure<br />

The structure of an arable injector is quite simple: the injectors<br />

are fastened on a double-beam chassis reinforced by radiant<br />

cross-pieces. The main advantage<br />

offered by this assembly is<br />

to focus the strains of the tool<br />

on the Universal chassis of the<br />

spreader, which then transfers<br />

them evenly on the tractor. The<br />

stress is then reduced and the<br />

tractor is not subjected to distorsion.<br />

Specificities<br />

In order not to exceed the maximum<br />

transport width and not to strike<br />

against obstacles, the Terraflex/2<br />

(5200/13 SHK & 5100/17 SHK) and<br />

Terraflex/3 injectors are fitted with<br />

retractable outer tines.<br />

The basic chassis is modular for all models of arable injectors. In<br />

this way, the large width models are based on 2.80 m models with<br />

extensions.<br />

The frame carrying the injectors<br />

wider than 3 meters are<br />

fitted with a double-acting hydraulic<br />

folding system with antitwisting<br />

safety stop. All the models<br />

are equipped with a road<br />

lighting system.<br />

The gauge wheels allow to adjust the working depth of the tines.<br />

The injectors are standard equipped with 2 gauge wheels 200/60-<br />

14.5 (Ø 605 x 210 mm) and can be <strong>com</strong>pleted by 2 other wheels<br />

available in option on the large widths from 5m10.<br />

In case of thicker slurry (cattle slurry,...) or higher doses per hectare,<br />

it is advisable to choose Ø 60 mm macerator outlets and pipes<br />

instead of Ø 48 mm ones (standard).<br />

-10-

Arable injectors<br />

Control of the hydraulic functions<br />

The arable injectors are standard operated by the Easymatic sequential<br />

block. This block operates the linkage and macerator while<br />

the valve opening takes place by direct connection to the tractor.<br />

In case of extra use of the Multi-Action injector, an adaptation of<br />

the Easymatic block into Easymatic+ is re<strong>com</strong>mended. A manual<br />

valve makes it then possible to operate the valve opening either by<br />

means of the block, or independently.<br />

In option, JOSKIN offers the Cleanmatic © . This device for<br />

automatic draining before digging up the injector is remarkably efficient:<br />

it avoids any loss of slurry on headland, in the farm yard, on<br />

the road, ...<br />

The Cleanmatic © can be operated automatically by the Instamatic ©<br />

hydraulic sequential block.<br />

JOSKIN Cleanmatic ©<br />

Range tables<br />

Terrasoc<br />

Type<br />

Widths<br />

Shares<br />

Work (m) Transport (m) Number Space (cm)<br />

Number of<br />

gauge wheels<br />

Folding<br />

Number of macerator<br />

outlets<br />

Mass<br />

(kg)<br />

2800/7 S 2.80 2.60 7 40 2 - 12 700<br />

3600/9 SH 3.60 2.80 9 40 2 Hydraulic 12 840<br />

4400/11 SH 4.40 2.80 11 40 2 Hydraulic 12 920<br />

5200/13 SH 5.20 2.84 13 40 2 Hydraulic 14 1000<br />

Terraflex/2<br />

Type<br />

Widths<br />

Shares<br />

Number of<br />

Number of macerator<br />

outlets (kg)<br />

Mass<br />

Folding<br />

Work (m) Transport (m) Number Space (cm)<br />

gauge wheels<br />

2800/7 SK 2.80 2.60 7 40 2 - 12 720<br />

4400/11 SHK 4.40 2.70 11 40 2 Hydraulic 12 860<br />

5200/13 SHK 5.20 2.60 13 40 2 Hydraulic 14 1040<br />

2700/9 SK 2.70 2.60 9 30 2 - 12 800<br />

3900/13 SHK 3.90 2.60 13 30 2 Hydraulic 14 1020<br />

4500/15 SHK 4.50 2.60 15 30 2 Hydraulic 16 1150<br />

5100/17 SHK 5.10 2.60 17 30 2 Hydraulic 20 1240<br />

Terraflex/3<br />

Type<br />

Widths<br />

Shares<br />

Work (m) Transport (m) Number Space (cm)<br />

Number of<br />

gauge wheels<br />

Folding<br />

Number of macerator<br />

outlets<br />

Mass<br />

(kg)<br />

4400/11 SHK/3 4.40 2.63 11 40 2 Hydraulic 12 1240<br />

5200/13 SHK/3 5.20 2.63 13 40 2 Hydraulic 14 1320<br />

6000/15 SHK/3 6.00 2.63 15 40 2 Hydraulic 16 1540<br />

5100/17 SHK/3 5.10 2.63 17 30 2 Hydraulic 20 1240<br />

5700/19 SHK/3 5.70 2.63 19 30 2 Hydraulic 20 1540<br />

- 11 -<br />

-11-

Terrasoc<br />

General points<br />

The Terrasoc arable injector is fitted with rigid tines<br />

- 40 cm spacing - and a shear-bolt security.<br />

These tines are ended by 24 cm wide duckfoot<br />

shares. Given the shape of the tines and the<br />

wide serration of the shares, the clogging risks<br />

are insignificant. The advantages of the system<br />

are:<br />

• efficient soil ploughing<br />

• injection depth ranging from 10 to 12 cm<br />

• outstanding stubble ploughing work<br />

(this type of share is best suited to mechanical<br />

weeding techniques)<br />

• less tractor power (see hereafter).<br />

Working<br />

The working principle of the TERRASOC is very simple: slurry <strong>com</strong>es<br />

from the macerator and flows through an injection hose following the<br />

curve of the tine. It is then laid down at the back of the tine, precisely<br />

under the foot of the share making a groove in the ground.<br />

With the Terrasoc, the slurry is injected on the whole share width<br />

(15 to 25 cm according to the type of slurry and ground). As<br />

slurry is distributed over a large width, there can be more space<br />

between the tines; in other words, this requires less power.<br />

The working depth is adjusted thanks to a central adjustment on<br />

the gauge wheels.<br />

Besides, it is possible to adjust the height of the tines individually<br />

by modifying their fixing point on the frame (3 positions). This<br />

operation is particularly easy, as the user merely has to screw and<br />

unscrew a few bolts.<br />

The sloping angle of the tines can also be modified in order to<br />

loosen the ground more or less effectively. This adjustment is also<br />

very easy, as only one bolt has to be moved (3 positions).<br />

Stubble plough<br />

The injector is fitted with a 3rd point hitch, so that it can<br />

be fixed to the standardized 3-point linkage of a tractor.<br />

In this way, the Terrasoc can be used as a simple stubble plough or<br />

as an umbilical system.<br />

-12-

Terraflex/2 - Terraflex/3<br />

General points<br />

The Terraflex models are fitted with Everstrong-type flexible<br />

tines (fixed on wide spring leaves) ended by a 6.5 cm wide<br />

reversible straight share.<br />

This type of tines allows:<br />

• improved ground loosening thanks to vibrating effect<br />

• good vegetal residue mixing (in limited quantity)<br />

• a perfectly torn plough soil and a better prepared seed bed<br />

• a working depth ranging from 12 to 15 cm<br />

As they are vibrating, these tines are more resistant<br />

to obstacles (stones,...) but offer a less<br />

regular working depth.<br />

680 mm<br />

The working principle of this injector is the<br />

same as for the Terrasoc: the share makes<br />

a groove in the ground and the slurry is<br />

then laid down by the injection hose.<br />

The working depth is adjusted thanks to a<br />

central adjustment on the gauge wheels.<br />

Like the Terrasoc, the Terraflex injector<br />

can be used as a stubble plough or as an<br />

umbilical system.<br />

Options<br />

In option, the Terraflex injectors may<br />

have Kongskilde Vibroflex type tines and<br />

reinforced blue shares.<br />

These tines, just as the standard ones,<br />

are designed to bury and mix larger<br />

quantities of straw and vegetal residue.<br />

Indeed, these tines have the following specifications:<br />

• plough beam with 2 folds allowing to make the earth go up and<br />

the vegetal matter down<br />

• a vertical zone (above the share) used to mix the vegetal matter<br />

and the ground in an optimal way<br />

As far as the blue shares are concerned, they offer the following<br />

major advantages:<br />

• 11 cm wide<br />

• further improved robustness<br />

• reversibility<br />

• designed for mulch seeding<br />

• very good mechanical seeding effect (roots and seeds).<br />

Terraflex/2 vs. Terraflex/3<br />

The global row<br />

spacing of the Terraflex/2<br />

and Terraflex/3<br />

is 30 or 40<br />

cm, according to<br />

the chosen model.<br />

On the Terraflex/3,<br />

the tines<br />

are distributed on<br />

3 rows instead of<br />

2 on the Terraflex/2,<br />

which allows a greater clearance between them. This injector<br />

is therefore particularly interesting when there is a lot of<br />

vegetal residue.<br />

The spacing between the 1st and 2nd row is moreover larger than<br />

between the 2nd and 3rd row.<br />

For countries in which the doses per hectare are significantly limited<br />

by new regulations, we advise the range of machines with<br />

30 cm between the tines in order to make sure slurry is evenly<br />

distributed on the ground.<br />

- 13 -<br />

-13-

Meadow injectors<br />

The JOSKIN meadow injectors are fitted with discs or skids.<br />

The range is available in two types of injectors: Multi-Action and Solodisc.<br />

Standardized frame<br />

Lighting<br />

A road lighting system is part of<br />

the standard equipment of the<br />

injectors.<br />

The highly <strong>com</strong>pact design and<br />

the folding system of the injector<br />

lead to a particularly limited overhang<br />

at the back of the slurry<br />

tanker, which makes it possible<br />

to significantly reduce the<br />

strains on the slurry tanker.<br />

In option, it is possible to choose<br />

truck-type lights.<br />

Pincers<br />

The meadow injectors are mounted on the same type of support.<br />

This standardization of the frame makes it possible to interchange<br />

the spreading elements. These single-beam frames are made of<br />

high tensile steel offering the best <strong>com</strong>promise between strength<br />

and lightness.<br />

The injectors are standard fitted with mechanical anti-drip pincers<br />

which automatically release the injection pipe when the injection<br />

element touches the ground (and inversely when the element is<br />

lifted from the ground).<br />

-14-

Meadow injectors<br />

Each pincer is fitted with a rounded jaw and a pinching stop in order<br />

to limit the wear to the rubber injection cone as much as possible.<br />

Hydraulic pincers are also available in option both on the Multi-<br />

Action and Solodisc.<br />

Free steering elements<br />

The injection elements are made up of 2 outlets and are fixed<br />

to the chassis by means of an axis. As a result, they can pivot<br />

by 30° in bends (15° to the left and 15° to the right) and the<br />

user does not have to lift the machine and does not damage<br />

the grass.<br />

Lockmatic<br />

The models that are more<br />

than three meters wide are<br />

fitted with a double acting<br />

(DA) hydraulic folding system<br />

in order to abide by the<br />

prescribed transport width.<br />

In this case, the folding system<br />

is fitted with the Lock-<br />

Matic © automatic locking in<br />

order to enhance the driving safety as much as possible, namely<br />

on the road. This locking device is operated by the same hydraulic<br />

function as the folding system, thanks to the steered valves.<br />

‘‘Wet surface’’ device<br />

The ‘‘Wet surface kit’’ valve: the Solodisc works by applying a constant<br />

pressure on the linkage. As a result, it is possible, when arriving<br />

in a humid place, that the injector goes deeper into the ground.<br />

Therefore, in order to maintain the same working depth everywhere,<br />

the Solodisc can be equipped with the ‘‘Wet surface kit’’ device<br />

allowing to lift the rear tool when going from a dry zone to a humid<br />

zone (see explanations page 9).<br />

- 15 -<br />

-15-

JOSKIN multi-action<br />

General points<br />

The major advantage of the Multi-Action remains its low weight.<br />

This injector <strong>com</strong>bines modularity, simplicity of the construction and<br />

requires very little maintenance. If, initially, it is a meadow injector, it<br />

can turn out to be multifunctional on certain grounds, stubble-fields<br />

or growing crops.<br />

Structure<br />

The Multi-Action is made up of a single-beam frame carrying free<br />

steering elements fixed with a 21,5 cm spacing. The end of each<br />

free steering element, which is fully galvanized and made up of two<br />

arms with independent deflection, is fitted with a self-sharpening<br />

share followed by an injection cone.<br />

working from a given<br />

operating height only,<br />

the stay springs allow<br />

to apply the shares<br />

on the ground with a<br />

given pressure. This<br />

pressure in 2 phases<br />

ensures ground clearance<br />

for the chassis<br />

and a flexibility in the<br />

deflection of the elements.<br />

The long arms on which the shares are fixed allow :<br />

• to ensure a great deflection up to 25 cm to <strong>com</strong>pensate the<br />

ground unevenness<br />

• to avoid all vibrations on the elements, even at a speed higher<br />

than 10km/h<br />

• to ensure a regular slurry deposit on the ground without splashing<br />

Locking the elements<br />

for transport<br />

The cutting share makes a groove in the ground, with an injection<br />

depth ranging from 0 to 3 cm. Then, slurry flows through the injection<br />

cone and is smoothly laid down in the middle of this groove<br />

without splashing the plants.<br />

The stay springs are also the base of the Multi-Action: <strong>com</strong>bined<br />

to the springs serving as mechanical shock absorbers and starting<br />

-16-<br />

Once the injector is folded, the<br />

elements which are situated on<br />

the upper arms are maintained<br />

in position by a locking system.<br />

A simple notch prevents each<br />

element from making a rotation<br />

round its axis and from falling<br />

down. The elements<br />

remain thus very rigid in<br />

relation to the vibrations<br />

due to transport.

JOSKIN multi-action<br />

Control of the hydraulic functions<br />

Concerning the hydraulic controls,<br />

the Multi-Action requires<br />

the use of the Easymatic+<br />

sequential block. This block<br />

operates the macerator, the<br />

linkage and the tank valve.<br />

However, it is not fitted with<br />

the function ensuring a constant<br />

pressure on the linkage,<br />

as the Multi-Action works<br />

thanks to its own weight. In<br />

option, it is possible to install<br />

an automatic reverser for the<br />

macerator with or without nitrogen<br />

balls (Switch-Matic).<br />

The electric reverser with manual<br />

control in the cabin is also available in option on this type of<br />

injector.<br />

If the Multi-Action is fitted with hydraulic pincers, it will then have to<br />

be equipped with an Instamatic sequential block. This block operates<br />

- beside the macerator, the linkage and the tank valve - the<br />

opening and closing of the pincers.<br />

Options<br />

Two other options can turn out to be particularly judicious on the<br />

Multi-Action:<br />

• the spring suspension<br />

for the linkage:<br />

this equipment<br />

makes it possible<br />

to take a part of<br />

the load of the injector<br />

in order to<br />

avoid this one from<br />

sinking too deeply<br />

into humid and<br />

spongy ground<br />

• discs (Ø 250 x 3<br />

mm) can be placed<br />

in front of<br />

the shares of the<br />

Multi-Action to<br />

work on grounds<br />

covered with a lot<br />

vegetal residue<br />

Type<br />

Work (m)<br />

Widths<br />

Transport (m)<br />

Number of<br />

elements<br />

Elements<br />

Space (cm)<br />

between shares<br />

Folding<br />

Number of macerator<br />

outlets<br />

(= nber of elements)<br />

Weight (kg)<br />

3010/14 MA 3.01 3.00 7 21.5 - 14 440<br />

4300/20 MAH 4.30 2.60 10 21.5 Hydraulic 20 860<br />

5160/24 MAH 5.16 2.60 12 21.5 Hydraulic 24 980<br />

6020/28 MAH 6.02 2.60 14 21.5 Hydraulic 28 1088<br />

6880/32 MAH 6.88 2.60 16 21.5 Hydraulic 32 1240<br />

7740/36 MAH 7.74 2.60 18 21.5 Hydraulic 36 1580<br />

- 17 -<br />

-17-

JOSKIN Solodisc<br />

The Solodisc is made up of free steering elements that are fully<br />

galvanized and each fitted with a pair of discs, followed by a<br />

2-position injection cone. The discs are placed at a distance of<br />

21.5 cm from each other. As far as the injection cone is concerned,<br />

it is made up of a galvanized spout, an anti-drip pincer and<br />

a very flexible injection cone of profiled rubber.<br />

pin and two symmetrical stay springs ensuring<br />

a constant spacing after a lateral<br />

movement (max. 30°).<br />

The injection depth<br />

is adjustable (max. 6<br />

cm). This one is kept<br />

constant thanks to a<br />

continuous pressure<br />

on the linkage. The<br />

pressure has simply<br />

to be modified, by<br />

means of an adjusting<br />

wheel, to adapt<br />

-18-<br />

General points<br />

The SOLODISC meadow injector is the ideal tool for a highly precise<br />

spreading on your meadows. It is made up of modular discs<br />

with large diameter (406 mm x 19 mm), which gives it its multifunctionality<br />

on growing crops, stubble-fields, etc.<br />

Structure<br />

The injector works as follows:<br />

the sharpened disc makes a<br />

neat and precise groove. The<br />

slurry is then laid down in the<br />

groove by the rubber cone<br />

that is situated just behind<br />

the disc.<br />

To remind you, the injection<br />

device rests on free steering<br />

elements made up of a hinge<br />

the working depth. It is also possible to modify the fixing points<br />

of the <strong>com</strong>plete elements on their frame to adjust the injection<br />

depth. Besides, springs are used as mechanical shock absorbers<br />

and apply the discs with a given pressure on the ground,<br />

thereby limiting the injection depth variations and allowing a vertical<br />

deflection of the elements in order to adapt to the transverse<br />

ground unevenness (up to 25 cm).<br />

In option, the Solodisc disc<br />

injector can be fitted with a<br />

cross-<strong>com</strong>pensation system<br />

with hydraulic circuit<br />

(instead of springs) keeping<br />

the same ground pressure<br />

for each element while preventing<br />

structure torsions<br />

(<strong>com</strong>municating vessels<br />

principle).<br />

Hydraulics<br />

If the injector is more than 3<br />

m wide, it is fitted with a hydraulic<br />

folding system. The<br />

transport width of the injectors with mechanical cross-<strong>com</strong>pensation<br />

is 2.68 m, while that of the injectors with hydraulic <strong>com</strong>pensation<br />

is 2.58 m.<br />

A <strong>com</strong>pression chamber is placed in the chassis<br />

and works on the hydraulic element <strong>com</strong>pensation.<br />

This <strong>com</strong>pression chamber automatically lifts every<br />

injection element to reduce the transport width<br />

of the Solodisc while increasing the ground clearance.<br />

Still to make transport more<br />

secure, a hydraulic mechanism with automatic<br />

control is also placed in the frame of the Solodisc<br />

in order to keep the elements perpendicular<br />

to the single-beam frame.

JOSKIN Solodisc<br />

Discs<br />

The Solodisc injector is also characterized by easily interchangeable<br />

discs. As a result, it is very easy to adapt the machine to your<br />

own needs. The self-sharpening discs (Ø 406 mm x 19 mm) are<br />

standard mounted on all machines. Made of cast steel, they are<br />

very resistant, and therefore everlasting. Another model of discs<br />

is also available in option:<br />

Ø 300 x 3 mm with shares.<br />

They allow to somewhat lighten<br />

the injector and penetrate<br />

more easily into the ground.<br />

These discs are <strong>com</strong>bined to<br />

groove widening shares in order<br />

to keep a correct spreading<br />

volume.<br />

The discs are mounted on hubs with<br />

(tightening) conical<br />

bearings,<br />

which are hermetically<br />

closed<br />

and over-dimensioned.<br />

Because<br />

of the resistance<br />

of the<br />

Ø 406 mm discs, the Solodisc requires less<br />

maintenance, even if it is used for years.<br />

Control of the hydraulic functions<br />

The Solodisc is standard fitted with the Polymatic hydraulic block,<br />

the use of which is very simple as the driver only has to operate<br />

one double-acting distributor in the cabin of the tractor.<br />

This hydraulic block automatically operates the following four<br />

functions:<br />

• starting and stopping the macerator<br />

• the linkage<br />

• opening and closing the rear valve<br />

• lifting or lowering the linkage, and applying the constant pressure<br />

on the ground<br />

The Instamatic block is required to operate all these functions<br />

with, beside, the hydraulic pincers.<br />

Options<br />

Among the most interesting options, it is important to mention:<br />

• The reverser of the macerator (re<strong>com</strong>mended) and the nitrogen<br />

balls.<br />

• The hydraulic pincers: the Solodisc is standard fitted with mechanical<br />

anti-drip pincers preventing any loss of slurry on headland<br />

and ensuring a carefull and even slurry injection at the beginning<br />

and at the end of a working lane.<br />

These pincers are mechanically opened<br />

and closed by the linkage. In option, the<br />

pincers can be operated by a single-acting<br />

hydraulic cylinder.<br />

Type<br />

Widths<br />

Discs<br />

Number of<br />

Transport Transport<br />

Folding macerator<br />

Work (m) (with mechanical (with hydraulic Number Space (cm)<br />

outlets<br />

<strong>com</strong>pensation) <strong>com</strong>pensation)<br />

Weight (kg)<br />

3010/14 SD 3.01 3.00 3.00 14 21.5 - 14 840<br />

4300/20 SDH 4.30 2.68 2.58 20 21.5 Hydraulic 20 1400<br />

5160/24 SDH 5.16 2.68 2.58 24 21.5 Hydraulic 24 1780<br />

6020/28 SDH 6.02 2.68 2.58 28 21.5 Hydraulic 28 1980<br />

6880/32 SDH 6.88 2.68 2.58 32 21.5 Hydraulic 32 2200<br />

7740/36 SDH 7.74 2.68 2.58 36 21.5 Hydraulic 36 2400<br />

- 19 -<br />

-19-

twinjet boom<br />

The Twinjet spreading boom makes it possible to spread slurry in a<br />

traditional way by means of a ‘‘dual-nozzle’’ system. The two nozzles<br />

have a swinging scatterer at their end, allowing to spread over<br />

a very large width.<br />

The swinging scatterer is activated by the spreading pressure,<br />

<strong>com</strong>bined with an ingenious mechanical system. Thanks to this design,<br />

slurry is thrown out alternately in one and the other direction,<br />

so that these sheets offer a very low air resistance.<br />

The slurry transfer device is based on the <strong>com</strong>pression system of<br />

the spreader. At the exit of the tank, the slurry is distributed through<br />

a distribution box with two outlets, then it is expelled towards the<br />

swinging scatterers, which distribute it in sheets, the width of which<br />

can be adjusted.<br />

The distribution box has two Ø 125 mm outlets with quick coupling<br />

and includes a deflecting<br />

plate, holding back most of<br />

the foreign bodies (‘‘stone<br />

trap’’). This stone trap is then<br />

emptied easily by an access<br />

to the distribution box.<br />

The boom, which is mounted<br />

on cross-pieces with<br />

height adjustment or on linkage<br />

(option), is fitted with<br />

a hydraulic folding system<br />

operated by two DA cylinders.<br />

The JOSKIN spreading booms are fitted with self-lubrificating<br />

bushings.<br />

Type Spreading widths (m) Number of nozzles Folding<br />

15/2 RM 15 2 Hydraulic<br />

18/2 RM 18 2 Hydraulic<br />

21/2 RM 21 2 Hydraulic<br />

24/2 RM 24 2 Hydraulic<br />

-20-

multitwist boom<br />

The JOSKIN Multitwist multi-nozzle spreading booms allow<br />

to spread slurry over a large width (12 to 24 m), close to the<br />

ground, under the form of ‘‘umbrella-like’’ jets.<br />

This spreading tool is made up of two main pipes supported by<br />

two triangular frames. In the 12 m version, the two main pipes<br />

feed each of the four nozzles ended by vanes.<br />

The slurry transfer circuit starts at a collector, which distributes<br />

the slurry <strong>com</strong>ing from the tank through two rubber flexible pipes<br />

(Ø 125 mm). These pipes bring slurry in a straight line to the middle<br />

of each main pipe, so that the flow is not slackened and the<br />

pressure is optimal and uniform on each spreading nozzle.<br />

The projection system mounted at the end of each smaller nozzle<br />

is made of a rubber cone directed to a circular deflector. A rear<br />

plate ensures an even spreading.<br />

A quick opening cap, fixed on the outer ends of the main nozzles,<br />

allows to clean easily and quickly.<br />

The JOSKIN Multitwist boom is usually fixed to galvanized<br />

cross-pieces (with height adjustment), but can also be mounted<br />

on a 4-point linkage.<br />

The advantages of the Multitwist spreading boom<br />

are: large spreading width, ease of use, even distribution<br />

of slurry on the ground. The projection height<br />

(50 - 60 cm) ensures a very low wind resistance and<br />

contributes to the uniformity of the spreading pattern.<br />

For a clean transport, without slurry losses, the Twist<br />

system allows a 150° rotation of the boom.<br />

Besides this anti-drip function, the Twist system has other advantages:<br />

• it makes the linkage ‘‘secondary’’<br />

• it offers a limited overhang<br />

• it allows, in option, to spread with an exact scatterer without<br />

having to take off the boom The macerator, as well as two<br />

manual or hydraulic valves, have just to be added on the distribution<br />

box.<br />

The JOSKIN<br />

Multitwist boom is fitted<br />

with a hydraulic<br />

folding system. The<br />

articulating points of<br />

the boom has been<br />

designed in such a<br />

way that their transport<br />

width does not<br />

exceed 3 metres.<br />

During transport, the<br />

whole is fastened by<br />

a boom clipping system.<br />

This system has a height adjustment system and a craddle<br />

with a damping rubber.<br />

Another safety that can turn out to be very useful in certain conditions<br />

is the anti-crash safety system.<br />

This system is standard mounted on all<br />

Multitwist booms and consists in<br />

fitting each boom wing with an articulation<br />

and stay springs. In this<br />

way, when spreading on a bumpy<br />

ground, the ends of the boom will<br />

retract (max. 55 cm) when hitting<br />

the ground. Mounting the wings at<br />

the end of the oblong holes allows them to pivot and to go back<br />

to their initial position.<br />

Type Spreading widths (m) Number of nozzles Folding Weight (kg)<br />

12/8 RH 12 8 Hydraulic 870<br />

15/10 RH 15 10 Hydraulic 930<br />

18/12 RH 18 12 Hydraulic 990<br />

24/16 RH 24 16 Hydraulic 1200<br />

- 21 -<br />

-21-

Penditwist boom<br />

General points<br />

From an agronomic point of view, the JOSKIN Penditwist line<br />

spreading boom is very interesting as it makes it possible to lay<br />

slurry at the foot of the plants without slowing down on the ground<br />

of the vegetation and with no slurry residue in the forage (essential<br />

for grass and maize silage). Moreover, because it is manufactured<br />

in fully galvanized steel, it offers very interesting durability characteristics.<br />

The machine is made up of a triangular structure articulated<br />

on a central frame and supporting line spreading hoses that are<br />

fixed at regular intervals (250 or 300 mm according to the type of<br />

boom).<br />

The working principle of the Penditwist boom is very simple. Coming<br />

from the tank, the slurry goes through one (two) macerator(s) before<br />

flowing into the pipes and being softly laid down on the ground.<br />

Macerator<br />

The macerator is of utmost importance in order to make sure the<br />

Penditwist works properly. The 9 m booms have one single macerator<br />

while the booms from 12 m have two of them, in order to get<br />

a greater reactivity at the beginning of the spreading phase and to<br />

reduce the load losses (slurry is more uniformly spread).<br />

The macerators of the Penditwist are vertical<br />

and have horizontal outlets allowing to<br />

place the pipes in an optimal way. As a result,<br />

the load losses are limited and slurry<br />

is more homogeneously distributed, even<br />

at the end of a 18 m boom. The advantage<br />

of vertical macerators is their small overall<br />

dimensions. The total height of the boom is<br />

therefore limited.<br />

An electric reverser on macerator is standard<br />

mounted on each model, with a purpose-made control in the<br />

tractor cabin (see details page 8).<br />

Control of the hydraulic functions<br />

The simplified hydraulic control of the boom is ensured by the Easymatic<br />

sequential block operating the start of the macerator(s) as<br />

well as the linkage.<br />

Hitching<br />

The JOSKIN Penditwist booms are standard fitted with linking<br />

cross-pieces allowing the height adjustment. These cross-pieces<br />

are then hitched to the JOSKIN 4-point linkage of the spreader.<br />

Hydraulic folding<br />

All booms are fitted with the hydraulic folding system and the Twist<br />

system. This last allows to obtain the best anti-drip system ever.<br />

The Twist system turns the line spreading hoses <strong>com</strong>pletely over,<br />

thereby avoiding any loss of slurry on the road while helping to<br />

protect the environment. Other advantage of the Twist system: the<br />

line spreading hoses are pointed backwards and smootly lay slurry<br />

down without splashing (see photos page 23). The <strong>com</strong>pletely folded<br />

boom has an insignificant overhang that does not affect at all<br />

the driving of the carriage.<br />

The hydraulic folding system has the following parameters:<br />

• hydraulic safety device<br />

• locking of the boom wings in transport position thanks to interlocking<br />

supports<br />

• rams positioned askew (not vertically) to better hold the boom in<br />

position (reduction of the swinging movement)<br />

For the wide spreading booms, there is a double hydraulic folding<br />

system, significantly reducing the bulk along the tank<br />

(in option on 15 m and standard on 18 m).<br />

For higher safety, the folded boom is such that the position of the<br />

macerators is pointed inwards so as not to exceed the boom size.<br />

Moreover, each boom is standard fitted with an anti-crash safety<br />

system allowing a potential boom deflection of 55 cm in case it<br />

woud <strong>com</strong>e into contact with an obstacle.<br />

Traditional spreading<br />

Provided your slurry tanker is equipped with the<br />

option ‘‘Exact scatterer through linkage’’, it is<br />

always possible to spread in a traditional way.<br />

Thanks to the height adjustment by means of<br />

the cross-pieces, it is not necessary to remove<br />

the boom to spread in sheets.<br />

-22-

Penditwist boom<br />

Opening sequence of the JOSKIN Penditwist boom<br />

A supporting bracket for transport is of course included in the standard equipment. When folding, the boom is fastened by means of hooks<br />

in the lateral supports fixed to the tank brackets.<br />

➊<br />

➋<br />

➌<br />

➍<br />

Type<br />

Widths<br />

Hoses<br />

Work (m) Transport (m) Number Space (cm)<br />

Folding<br />

Number of macerators<br />

x outlets<br />

90/30 RT1 9 m 2.55 m 30 30 Hydraulic 1 x 30<br />

90/36 RT1 9 m 2.55 m 36 25 Hydraulic 1 x 36<br />

120/40 RT2 12 m 2.55 m 40 30 Hydraulic 2 x 20<br />

120/48 RT2 12 m 2.55 m 48 25 Hydraulic 2 x 26<br />

150/50 RT2 15 m 2.55 m 50 30 Hydraulic 2 x 26<br />

150/60 RT2 15 m 2.55 m 60 25 Hydraulic 2 x 30<br />

180/60 RT2 18 m 2.55 m 60 30 Hydraulic 2 x 30<br />

180/72 RT2 18 m 2.55 m 72 25 Hydraulic 2 x 36<br />

For the Vogelsang booms, please contact us<br />

Type Spreading width (m) Transport (m) Pipe distance Folding<br />

Number of macerators<br />

x outlets<br />

SwingMax3 21 m 2.55 m 26 cm Hydraulic 2 x 40<br />

SwingMax3 24 m 2.55 m 30 cm Hydraulic 2 x 40<br />

SwingMax3S 24 m S (1) 2.55 m 30 cm Hydraulic 2 x 40<br />

SwingMax 27 m 2.55 m 28 cm Hydraulic 2 x 48<br />

SwingMax3S 27 m S (1) 2.55 m 28 cm Hydraulic 2 x 48<br />

SwingMax3 30 m 2.55 m 30 cm Hydraulic 2 x 48<br />

(1)<br />

with TeleShift at the front included<br />

- 23 -<br />

-23-

<strong>www</strong>.<strong>joskin</strong>.<strong>com</strong><br />

Terrasoc<br />

Terraflex/3<br />

solodisc<br />

twinjet<br />

Terraflex/2<br />

multi-action<br />

multitwist<br />

penditwist<br />

JOSKIN rear tools,<br />

the tools to make your slurry profitable<br />

Rue de Wergifosse, 39<br />

B-4630 Soumagne - Belgium<br />

E40 - exit 37 Herve - Soumagne<br />

Your local Joskin partner<br />

Tel.: +32 (0) 43 77 35 45<br />

Fax: +32 (0) 43 77 10 15<br />

E-mail: info@<strong>joskin</strong>.<strong>com</strong><br />

©JOSKIN 11-2009. No-contractual document. Data can change without notice. The pictures don’t necessary correspond to standard equipment.