www.joskin.com

Spreading & injection equipment programme - joskin

Spreading & injection equipment programme - joskin

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Slurry distribution<br />

-8-<br />

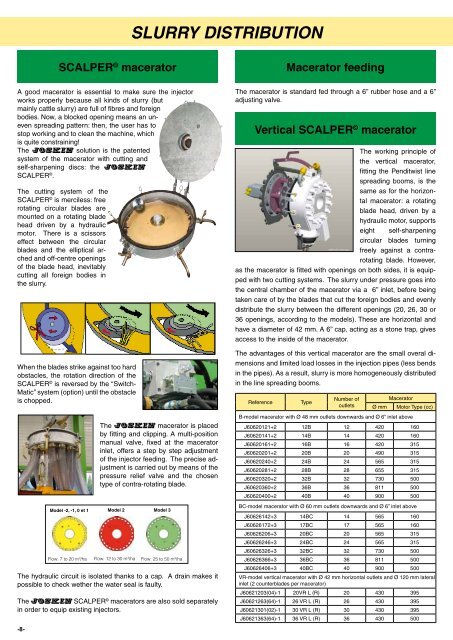

SCALPER © macerator<br />

A good macerator is essential to make sure the injector<br />

works properly because all kinds of slurry (but<br />

mainly cattle slurry) are full of fibres and foreign<br />

bodies. Now, a blocked opening means an uneven<br />

spreading pattern: then, the user has to<br />

stop working and to clean the machine, which<br />

is quite constraining!<br />

The JOSKIN solution is the patented<br />

system of the macerator with cutting and<br />

self-sharpening discs: the JOSKIN<br />

SCALPER © .<br />

The cutting system of the<br />

SCALPER © is merciless: free<br />

rotating circular blades are<br />

mounted on a rotating blade<br />

head driven by a hydraulic<br />

motor. There is a scissors<br />

effect between the circular<br />

blades and the elliptical arched<br />

and off-centre openings<br />

of the blade head, inevitably<br />

cutting all foreign bodies in<br />

the slurry.<br />

When the blades strike against too hard<br />

obstacles, the rotation direction of the<br />

SCALPER © is reversed by the ‘‘Switch-<br />

Matic’’ system (option) until the obstacle<br />

is chopped.<br />

The JOSKIN macerator is placed<br />

by fitting and clipping. A multi-position<br />

manual valve, fixed at the macerator<br />

inlet, offers a step by step adjustment<br />

of the injector feeding. The precise adjustment<br />

is carried out by means of the<br />

pressure relief valve and the chosen<br />

type of contra-rotating blade.<br />

Model -2, -1, 0 et 1 Model 2 Model 3<br />

Flow: 7 to 20 m³/ha<br />

Flow: 12 to 30 m³/ha<br />

Flow: 25 to 50 m³/ha<br />

The hydraulic circuit is isolated thanks to a cap. A drain makes it<br />

possible to check wether the water seal is faulty.<br />

The JOSKIN SCALPER © macerators are also sold separately<br />

in order to equip existing injectors.<br />

Macerator feeding<br />

The macerator is standard fed through a 6’’ rubber hose and a 6’’<br />

adjusting valve.<br />

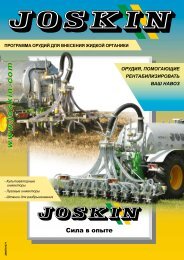

Vertical SCALPER © macerator<br />

The working principle of<br />

the vertical macerator,<br />

fitting the Penditwist line<br />

spreading booms, is the<br />

same as for the horizontal<br />

macerator: a rotating<br />

blade head, driven by a<br />

hydraulic motor, supports<br />

eight self-sharpening<br />

circular blades turning<br />

freely against a contrarotating<br />

blade. However,<br />

as the macerator is fitted with openings on both sides, it is equipped<br />

with two cutting systems. The slurry under pressure goes into<br />

the central chamber of the macerator via a 6’’ inlet, before being<br />

taken care of by the blades that cut the foreign bodies and evenly<br />

distribute the slurry between the different openings (20, 26, 30 or<br />

36 openings, according to the models). These are horizontal and<br />

have a diameter of 42 mm. A 6’’ cap, acting as a stone trap, gives<br />

access to the inside of the macerator.<br />

The advantages of this vertical macerator are the small overal dimensions<br />

and limited load losses in the injection pipes (less bends<br />

in the pipes). As a result, slurry is more homogeneously distributed<br />

in the line spreading booms.<br />

Reference<br />

Type<br />

Number of<br />

Macerator<br />

outlets Ø mm Motor Type (cc)<br />

B-model macerator with Ø 48 mm outlets downwards and Ø 6’’ inlet above<br />

J60620121+2 12B 12 420 160<br />

J60620141+2 14B 14 420 160<br />

J60620161+2 16B 16 420 315<br />

J60620201+2 20B 20 490 315<br />

J60620240+2 24B 24 565 315<br />

J60620281+2 28B 28 655 315<br />

J60620320+2 32B 32 730 500<br />

J60620360+2 36B 36 811 500<br />

J60620400+2 40B 40 900 500<br />

BC-model macerator with Ø 60 mm outlets downwards and Ø 6’’ inlet above<br />

J60626142+3 14BC 14 565 160<br />

J60626172+3 17BC 17 565 160<br />

J60626206+3 20BC 20 565 315<br />

J60626246+3 24BC 24 565 315<br />

J60626326+3 32BC 32 730 500<br />

J60626366+3 36BC 36 811 500<br />

J60626406+3 40BC 40 900 500<br />

VR-model vertical macerator with Ø 42 mm horizontal outlets and Ø 120 mm lateral<br />

inlet (2 counterblades per macerator)<br />

J60621203(04)-1 20VR L (R) 20 430 395<br />

J60621263(64)-1 26 VR L (R) 26 430 395<br />

J60621301(02)-1 30 VR L (R) 30 430 395<br />

J60621363(64)-1 36 VR L (R) 36 430 500