www.joskin.com

Spreading & injection equipment programme - joskin

Spreading & injection equipment programme - joskin

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

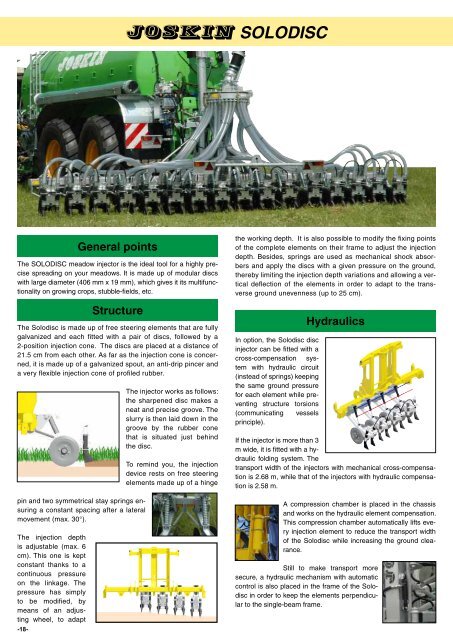

JOSKIN Solodisc<br />

The Solodisc is made up of free steering elements that are fully<br />

galvanized and each fitted with a pair of discs, followed by a<br />

2-position injection cone. The discs are placed at a distance of<br />

21.5 cm from each other. As far as the injection cone is concerned,<br />

it is made up of a galvanized spout, an anti-drip pincer and<br />

a very flexible injection cone of profiled rubber.<br />

pin and two symmetrical stay springs ensuring<br />

a constant spacing after a lateral<br />

movement (max. 30°).<br />

The injection depth<br />

is adjustable (max. 6<br />

cm). This one is kept<br />

constant thanks to a<br />

continuous pressure<br />

on the linkage. The<br />

pressure has simply<br />

to be modified, by<br />

means of an adjusting<br />

wheel, to adapt<br />

-18-<br />

General points<br />

The SOLODISC meadow injector is the ideal tool for a highly precise<br />

spreading on your meadows. It is made up of modular discs<br />

with large diameter (406 mm x 19 mm), which gives it its multifunctionality<br />

on growing crops, stubble-fields, etc.<br />

Structure<br />

The injector works as follows:<br />

the sharpened disc makes a<br />

neat and precise groove. The<br />

slurry is then laid down in the<br />

groove by the rubber cone<br />

that is situated just behind<br />

the disc.<br />

To remind you, the injection<br />

device rests on free steering<br />

elements made up of a hinge<br />

the working depth. It is also possible to modify the fixing points<br />

of the <strong>com</strong>plete elements on their frame to adjust the injection<br />

depth. Besides, springs are used as mechanical shock absorbers<br />

and apply the discs with a given pressure on the ground,<br />

thereby limiting the injection depth variations and allowing a vertical<br />

deflection of the elements in order to adapt to the transverse<br />

ground unevenness (up to 25 cm).<br />

In option, the Solodisc disc<br />

injector can be fitted with a<br />

cross-<strong>com</strong>pensation system<br />

with hydraulic circuit<br />

(instead of springs) keeping<br />

the same ground pressure<br />

for each element while preventing<br />

structure torsions<br />

(<strong>com</strong>municating vessels<br />

principle).<br />

Hydraulics<br />

If the injector is more than 3<br />

m wide, it is fitted with a hydraulic<br />

folding system. The<br />

transport width of the injectors with mechanical cross-<strong>com</strong>pensation<br />

is 2.68 m, while that of the injectors with hydraulic <strong>com</strong>pensation<br />

is 2.58 m.<br />

A <strong>com</strong>pression chamber is placed in the chassis<br />

and works on the hydraulic element <strong>com</strong>pensation.<br />

This <strong>com</strong>pression chamber automatically lifts every<br />

injection element to reduce the transport width<br />

of the Solodisc while increasing the ground clearance.<br />

Still to make transport more<br />

secure, a hydraulic mechanism with automatic<br />

control is also placed in the frame of the Solodisc<br />

in order to keep the elements perpendicular<br />

to the single-beam frame.