You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

D1.2.3.1 Compactness<br />

In Clauses 5.2.3, 5.2.4, and 5.2.5 of AS 4100, <strong>sections</strong> are described as compact, non-compact or<br />

slender. This type of categorisation provides a measure of the relative importance of yielding and local<br />

buckling on the effective section modulus.<br />

The tables include a column headed “compactness” where the compactness or otherwise of the <strong>sections</strong><br />

is indicated for a given axis of bending as follows:<br />

C compact<br />

N non-compact<br />

S slender<br />

These terms are important with respect to selecting the methods of analysis that may be used to determine<br />

the design action effects (see Clause 4.5 of AS 4100) or in using the provisions of Section 8 of AS 4100<br />

for designing members subject to combined actions. Clause 4.5 of AS 4100 does not currently permit<br />

plastic analysis when designing with structural hollow <strong>sections</strong>.<br />

Research has shown that most DuraGal hollow <strong>sections</strong> are suitable for design by plastic analysis and AS<br />

4100 will be revised as soon as possible. In the interim, for details of the research in a case study phone<br />

OneSteel Direct on Freecall 1800 1 STEEL (1800 1 78335) or Freefax 1800 101 141.<br />

D1.2.3.2 Effective Section Modulus<br />

Subsequent to the evaluation of “compactness” the effective section modulus (Z e ) is also tabulated. Z e is<br />

determined by the requirements of Clauses 5.2.2 to 5.2.5 inclusive, of AS 4100 and is used in the calculation<br />

of the nominal section moment capacity (M s ) as defined in Clause 5.2.1 of AS 4100.<br />

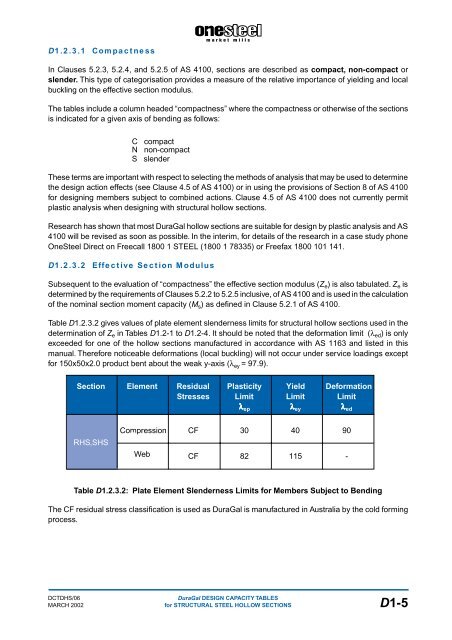

Table D1.2.3.2 gives values of plate element slenderness limits for structural hollow <strong>sections</strong> used in the<br />

determination of Z e in Tables D1.2-1 to D1.2-4. It should be noted that the deformation limit (λ ed ) is only<br />

exceeded for one of the hollow <strong>sections</strong> manufactured in accordance with AS 1163 and listed in this<br />

manual. Therefore noticeable deformations (local buckling) will not occur under service loadings except<br />

for 150x50x2.0 product bent about the weak y-axis (λ ey = 97.9).<br />

Section Element Residual Plasticity Yield Deformation<br />

Stresses Limit Limit Limit<br />

λ ep λ ey λ ed<br />

RHS,SHS<br />

Compression CF 30 40 90<br />

Flange<br />

Web CF 82 115 -<br />

Table D1.2.3.2: Plate Element Slenderness Limits for Members Subject to Bending<br />

The CF residual stress classification is used as DuraGal is manufactured in Australia by the cold forming<br />

process.<br />

DCTDHS/06<br />

DuraGal DESIGN CAPACITY TABLES<br />

MARCH 2002 for STRUCTURAL STEEL HOLLOW SECTIONS D1-5