You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

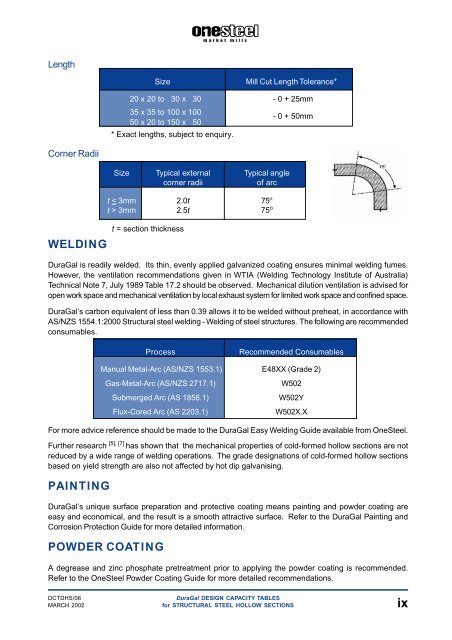

Length<br />

Size<br />

Mill Cut Length Tolerance*<br />

20 x 20 to 30 x 30 - 0 + 25mm<br />

35 x 35 to 100 x 100<br />

50 x 20 to 150 x 50<br />

- 0 + 50mm<br />

* Exact lengths, subject to enquiry.<br />

Corner Radii<br />

Size Typical external Typical angle<br />

corner radii<br />

of arc<br />

t < 3mm 2.0t 75 ο<br />

t > 3mm 2.5t 75 o<br />

WELDING<br />

t = section thickness<br />

DuraGal is readily welded. Its thin, evenly applied galvanized coating ensures minimal welding fumes.<br />

However, the ventilation recommendations given in WTIA (Welding Technology Institute of Australia)<br />

Technical Note 7, July 1989 Table 17.2 should be observed. Mechanical dilution ventilation is advised for<br />

open work space and mechanical ventilation by local exhaust system for limited work space and confined space.<br />

DuraGal’s carbon equivalent of less than 0.39 allows it to be welded without preheat, in accordance with<br />

AS/NZS 1554.1:2000 Structural steel welding - Welding of steel structures. The following are recommended<br />

consumables.<br />

Process<br />

Recommended Consumables<br />

Manual Metal-Arc (AS/NZS 1553.1) E48XX (Grade 2)<br />

Gas-Metal-Arc (AS/NZS 2717.1)<br />

Submerged Arc (AS 1858.1)<br />

Flux-Cored Arc (AS 2203.1)<br />

W502<br />

W502Y<br />

W502X.X<br />

For more advice reference should be made to the DuraGal Easy Welding Guide available from OneSteel.<br />

Further research [5], [7] has shown that the mechanical properties of cold-formed hollow <strong>sections</strong> are not<br />

reduced by a wide range of welding operations. The grade designations of cold-formed hollow <strong>sections</strong><br />

based on yield strength are also not affected by hot dip galvanising.<br />

PAINTING<br />

DuraGal’s unique surface preparation and protective coating means painting and powder coating are<br />

easy and economical, and the result is a smooth attractive surface. Refer to the DuraGal Painting and<br />

Corrosion Protection Guide for more detailed information.<br />

POWDER COATING<br />

A degrease and zinc phosphate pretreatment prior to applying the powder coating is recommended.<br />

Refer to the OneSteel Powder Coating Guide for more detailed recommendations.<br />

DCTDHS/06<br />

DuraGal DESIGN CAPACITY TABLES<br />

MARCH 2002 for STRUCTURAL STEEL HOLLOW SECTIONS ix