- Page 1 and 2: DuraGal ® design capacity tables f

- Page 3 and 4: CONTENTS Page Foreword ............

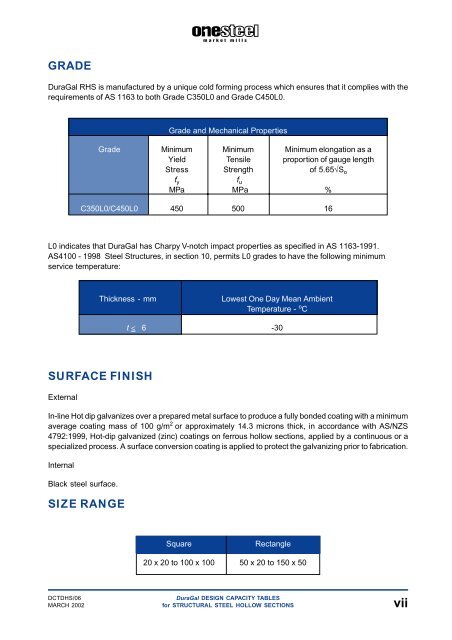

- Page 5: PREFACE DuraGal RHS is manufactured

- Page 9 and 10: Length Size Mill Cut Length Toleran

- Page 11 and 12: LIMIT STATES TES DESIGN USING THESE

- Page 13 and 14: PROPERTIES OF STEEL The properties

- Page 15 and 16: M ry M s M sx M sy M z M * M * m M

- Page 17 and 18: PART 1 SECTION PROPERTIES 1 PAGE D1

- Page 19 and 20: D1.2.1.1 Torsion Constants The tors

- Page 21 and 22: D1.2.3.1 Compactness In Clauses 5.2

- Page 23 and 24: D1.3 PROPERTIES FOR FIRE DESIGN To

- Page 25 and 26: Figure D1.4.2: Telescoping Data DCT

- Page 27 and 28: DCTDHS/06 DuraGal DESIGN CAPACITY T

- Page 29 and 30: DCTDHS/06 DuraGal DESIGN CAPACITY T

- Page 31 and 32: DCTDHS/06 DuraGal DESIGN CAPACITY T

- Page 33 and 34: TABLE D1.3-1(A) FIRE ENGINEERING DE

- Page 35 and 36: TABLE D1.3-2(A) FIRE ENGINEERING DE

- Page 37 and 38: TABLE D1.3-4 FIRE ENGINEERING DESIG

- Page 39 and 40: TABLE D1.4-2 DuraGal TELESCOPING IN

- Page 41 and 42: PART 2 DETERMINATION OF DESIGN ACTI

- Page 43 and 44: Figure D2.2: First-order Analysis a

- Page 45 and 46: PART 3 SECTION CAPACITIES 3 PAGE D3

- Page 47 and 48: D3.2.3 Design Moment Section Capaci

- Page 49 and 50: [ BLANK ] DCTDHS/06 DuraGal DESIGN

- Page 51 and 52: TABLE D3.1-2 DESIGN SECTION CAPACIT

- Page 53 and 54: PART 4 MEMBERS SUBECT TO BENDING 4

- Page 55 and 56: D4.1.3 Segment Length for Full Late

- Page 57 and 58:

Table D4.1.5(1) Values of (M sx /M

- Page 59 and 60:

A rectangular hollow section is the

- Page 61 and 62:

2. Check the shear capacity of the

- Page 63 and 64:

End bearing for b d < 1.5d 5 d5 b b

- Page 65 and 66:

D4.4 BENDING AND BEARING INTERACTIO

- Page 67 and 68:

D4.5 CALCULATION OF BEAM DEFLECTION

- Page 69 and 70:

DCTDHS/06 DuraGal DESIGN CAPACITY T

- Page 71 and 72:

TABLE D4.3-1(A) DESIGN WEB CAPACITI

- Page 73 and 74:

TABLE D4.3-2(A) DESIGN WEB CAPACITI

- Page 75 and 76:

TABLE D4.3-4 DESIGN WEB CAPACITIES

- Page 77 and 78:

PART 5 MEMBERS SUBECT TO AXIAL COMP

- Page 79 and 80:

According to Clause 6.3.3 of AS 410

- Page 81 and 82:

In all cases L e / L > 0.5 (i) Chor

- Page 83 and 84:

[ BLANK ] DCTDHS/06 DuraGal DESIGN

- Page 85 and 86:

DCTDHS/06 DuraGal DESIGN CAPACITY T

- Page 87 and 88:

DCTDHS/06 DuraGal DESIGN CAPACITY T

- Page 89 and 90:

DCTDHS/06 DuraGal DESIGN CAPACITY T

- Page 91 and 92:

DCTDHS/06 DuraGal DESIGN CAPACITY T

- Page 93 and 94:

PART 6 MEMBERS SUBJECT TO AXIAL TEN

- Page 95 and 96:

D6.3 EXAMPLE 1. A tension member wi

- Page 97 and 98:

TABLE D6.1-3 DESIGN CAPACITIES FOR

- Page 99 and 100:

PART 7 MEMBERS SUBJECT TO COMBINED

- Page 101 and 102:

If an appropriate second order elas

- Page 103 and 104:

Determination of δ s Members with

- Page 105 and 106:

D7.4 COMBINED BENDING AND AXIAL COM

- Page 107 and 108:

(b) Out-of-plane capacity where φM

- Page 109 and 110:

D7.4.3.2 Member Capacity 14 . 14 .

- Page 111 and 112:

D7.5.2.1 Section Capacity For The v

- Page 113 and 114:

D7.6 BIAXIAL BENDING For a member s

- Page 115 and 116:

From Figure D7.3(1) the moment ampl

- Page 117 and 118:

D7.7 EXAMPLES Example 2.0 Braced Be

- Page 119 and 120:

Then φM rx * N = 118 . ⎛ ⎞ φM

- Page 121 and 122:

DCTDHS/06 DuraGal DESIGN CAPACITY T

- Page 123 and 124:

DCTDHS/06 DuraGal DESIGN CAPACITY T

- Page 125 and 126:

DCTDHS/06 DuraGal DESIGN CAPACITY T

- Page 127 and 128:

DCTDHS/06 DuraGal DESIGN CAPACITY T

- Page 129 and 130:

[ BLANK ] DCTDHS/06 DuraGal DESIGN

- Page 131 and 132:

PART 8 MAXIMUM DESIGN LOADS FOR BEA

- Page 133 and 134:

D8.2.2 Serviceability Limit State D

- Page 135 and 136:

D8.5 OTHER LOAD CONDITIONS The valu

- Page 137 and 138:

(b) Use of the Tables: Strength Lim

- Page 139 and 140:

DuraGal DESIGN CAPACITY TABLES DCTD

- Page 141 and 142:

DuraGal DESIGN CAPACITY TABLES DCTD

- Page 143 and 144:

DuraGal DESIGN CAPACITY TABLES DCTD

- Page 145 and 146:

DuraGal DESIGN CAPACITY TABLES DCTD

- Page 147 and 148:

DuraGal DESIGN CAPACITY TABLES DCTD

- Page 149 and 150:

DuraGal DESIGN CAPACITY TABLES DCTD

- Page 151 and 152:

DuraGal DESIGN CAPACITY TABLES DCTD

- Page 153 and 154:

DuraGal DESIGN CAPACITY TABLES DCTD

- Page 155 and 156:

DuraGal DESIGN CAPACITY TABLES DCTD

- Page 157 and 158:

DuraGal DESIGN CAPACITY TABLES DCTD

- Page 159 and 160:

DuraGal DESIGN CAPACITY TABLES DCTD

- Page 161 and 162:

DuraGal DESIGN CAPACITY TABLES DCTD

- Page 163 and 164:

DuraGal DESIGN CAPACITY TABLES DCTD

- Page 165 and 166:

DuraGal DESIGN CAPACITY TABLES DCTD

- Page 167 and 168:

DuraGal DESIGN CAPACITY TABLES DCTD

- Page 169 and 170:

DuraGal DESIGN CAPACITY TABLES DCTD

- Page 171 and 172:

DuraGal DESIGN CAPACITY TABLES DCTD

- Page 173 and 174:

DuraGal DESIGN CAPACITY TABLES DCTD

- Page 175 and 176:

DuraGal DESIGN CAPACITY TABLES DCTD

- Page 177 and 178:

DuraGal DESIGN CAPACITY TABLES DCTD

- Page 179 and 180:

DuraGal DESIGN CAPACITY TABLES DCTD

- Page 181 and 182:

DuraGal DESIGN CAPACITY TABLES DCTD

- Page 183 and 184:

DuraGal DESIGN CAPACITY TABLES DCTD

- Page 185 and 186:

DuraGal DESIGN CAPACITY TABLES DCTD

- Page 187:

[ BLANK ] Courtesy of Econo Steel r