ORION Commercial 'LULA' Elevator - Advanced Lift Solutions

ORION Commercial 'LULA' Elevator - Advanced Lift Solutions

ORION Commercial 'LULA' Elevator - Advanced Lift Solutions

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

5.0 HYDRAULIC INSTALLATION<br />

When the EPV-12 is installed, the oil line must have a minimum<br />

¾” dia. with a ½” dia. NPT adapter at the jack.<br />

Steel Piping<br />

Before connecting the oil line, clean it out<br />

by placing the jack end of the oil line into<br />

a bucket and running the pump enough to<br />

flush out a cup or two of oil. DO NOT PUT<br />

THIS OIL BACK IN THE TANK!<br />

Make sure the pipe and fittings have the<br />

proper rating. Most jurisdictions require<br />

minimum Schedule 40 oil line and fittings.<br />

When routing the oil line to the hydraulic jack<br />

assembly, always minimize the number of<br />

90 o bends in the line. Each 90 o bend causes<br />

pressure loss and increases the noise level,<br />

as the elevator operates.<br />

Insulate the oil line where it passes through<br />

the hoistway wall to prevent vibration.<br />

The code permits the use of hydraulic<br />

hose within the machine (pump) room. It<br />

is recommended practice to install a short<br />

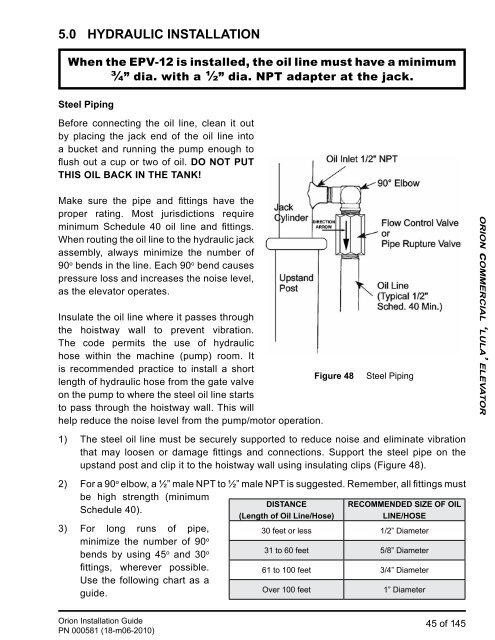

figure 48 Steel Piping<br />

length of hydraulic hose from the gate valve<br />

on the pump to where the steel oil line starts<br />

to pass through the hoistway wall. This will<br />

help reduce the noise level from the pump/motor operation.<br />

1) The steel oil line must be securely supported to reduce noise and eliminate vibration<br />

that may loosen or damage fittings and connections. Support the steel pipe on the<br />

upstand post and clip it to the hoistway wall using insulating clips (Figure 48).<br />

2) For a 90o elbow, a ½” male NPT to ½” male NPT is suggested. Remember, all fittings must<br />

be high strength (minimum<br />

Schedule 40).<br />

DISTANCE<br />

RECOMMENDED SIZE Of OIL<br />

3) For long runs of pipe,<br />

minimize the number of 90 o<br />

bends by using 45 o and 30 o<br />

fittings, wherever possible.<br />

Use the following chart as a<br />

guide.<br />

Orion Installation Guide<br />

PN 000581 (18-m06-2010)<br />

(Length of Oil Line/Hose)<br />

LINE/HOSE<br />

30 feet or less 1/2” Diameter<br />

31 to 60 feet 5/8” Diameter<br />

61 to 100 feet 3/4” Diameter<br />

Over 100 feet 1” Diameter<br />

45 of 145<br />

o r i o n co m m e r c i a l ‘l u l a’ e l e vato r