3-phase TEFV induction motors ATEX GAS - Zones 1 & 2

3-phase TEFV induction motors ATEX GAS - Zones 1 & 2

3-phase TEFV induction motors ATEX GAS - Zones 1 & 2

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

20<br />

3-<strong>phase</strong> <strong>TEFV</strong> <strong>induction</strong> <strong>motors</strong><br />

<strong>ATEX</strong> <strong>GAS</strong> - <strong>Zones</strong> 1 & 2<br />

Environment<br />

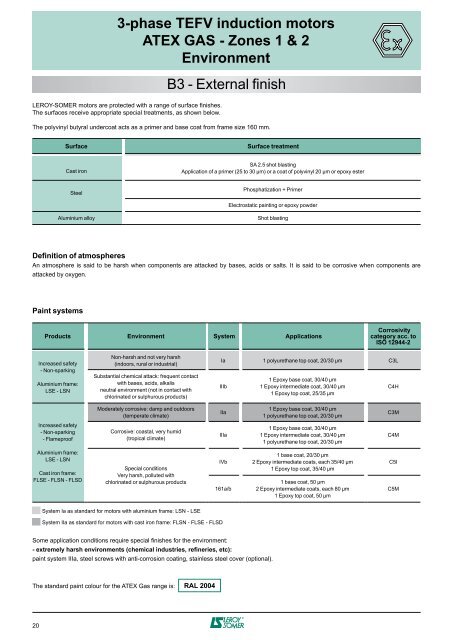

LEROY-SOMER <strong>motors</strong> are protected with a range of surface finishes.<br />

The surfaces receive appropriate special treatments, as shown below.<br />

B3 - External finish<br />

The polyvinyl butyral undercoat acts as a primer and base coat from frame size 160 mm.<br />

Surface Surface treatment<br />

Cast iron<br />

Steel<br />

SA 2.5 shot blasting<br />

Application of a primer (25 to 30 μm) or a coat of polyvinyl 20 μm or epoxy ester<br />

Phosphatization + Primer<br />

Electrostatic painting or epoxy powder<br />

Aluminium alloy Shot blasting<br />

Definition of atmospheres<br />

An atmosphere is said to be harsh when components are attacked by bases, acids or salts. It is said to be corrosive when components are<br />

attacked by oxygen.<br />

Paint systems<br />

Products Environment System Applications<br />

Increased safety<br />

- Non-sparking<br />

Aluminium frame:<br />

LSE - LSN<br />

Increased safety<br />

- Non-sparking<br />

- Flameproof<br />

Aluminium frame:<br />

LSE - LSN<br />

Cast iron frame:<br />

FLSE - FLSN - FLSD<br />

Non-harsh and not very harsh<br />

(indoors, rural or industrial)<br />

Substantial chemical attack: frequent contact<br />

with bases, acids, alkalis<br />

neutral environment (not in contact with<br />

chlorinated or sulphurous products)<br />

Moderately corrosive: damp and outdoors<br />

(temperate climate)<br />

Corrosive: coastal, very humid<br />

(tropical climate)<br />

Special conditions<br />

Very harsh, polluted with<br />

chlorinated or sulphurous products<br />

System Ia as standard for <strong>motors</strong> with aluminium frame: LSN - LSE<br />

System IIa as standard for <strong>motors</strong> with cast iron frame: FLSN - FLSE - FLSD<br />

Corrosivity<br />

category acc. to<br />

ISO 12944-2<br />

Ia 1 polyurethane top coat, 20/30 μm C3L<br />

IIIb<br />

IIa<br />

IIIa<br />

IVb<br />

161a/b<br />

Some application conditions require special finishes for the environment:<br />

- extremely harsh environments (chemical industries, refineries, etc):<br />

paint system IIIa, steel screws with anti-corrosion coating, stainless steel cover (optional).<br />

The standard paint colour for the <strong>ATEX</strong> Gas range is: RAL 2004<br />

1 Epoxy base coat, 30/40 μm<br />

1 Epoxy intermediate coat, 30/40 μm<br />

1 Epoxy top coat, 25/35 μm<br />

1 Epoxy base coat, 30/40 μm<br />

1 polyurethane top coat, 20/30 μm<br />

1 Epoxy base coat, 30/40 μm<br />

1 Epoxy intermediate coat, 30/40 μm<br />

1 polyurethane top coat, 20/30 μm<br />

1 base coat, 20/30 μm<br />

2 Epoxy intermediate coats, each 35/40 μm<br />

1 Epoxy top coat, 35/40 μm<br />

1 base coat, 50 μm<br />

2 Epoxy intermediate coats, each 80 μm<br />

1 Epoxy top coat, 50 μm<br />

C4H<br />

C3M<br />

C4M<br />

C5I<br />

C5M