AT&S World

AT&S World

AT&S World

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

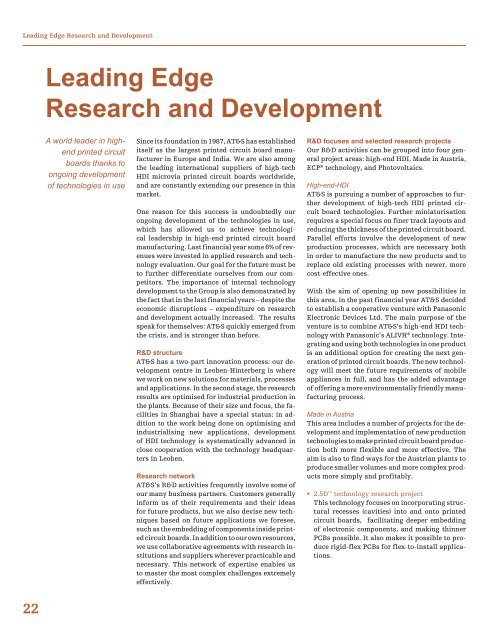

Leading Edge Research and Development<br />

22<br />

Leading Edge<br />

Research and Development<br />

A world leader in highend<br />

printed circuit<br />

boards thanks to<br />

ongoing development<br />

of technologies in use<br />

Since its foundation in 1987, AT&S has established<br />

itself as the largest printed circuit board manufacturer<br />

in Europe and India. We are also among<br />

the leading international suppliers of high-tech<br />

HDI microvia printed circuit boards worldwide,<br />

and are constantly extending our presence in this<br />

market.<br />

One reason for this success is undoubtedly our<br />

ongoing development of the technologies in use,<br />

which has allowed us to achieve technological<br />

leadership in high-end printed circuit board<br />

manufacturing. Last financial year some 6% of revenues<br />

were invested in applied research and technology<br />

evaluation. Our goal for the future must be<br />

to further differentiate ourselves from our competitors.<br />

The importance of internal technology<br />

development to the Group is also demonstrated by<br />

the fact that in the last financial years – despite the<br />

economic disruptions – expenditure on research<br />

and development actually increased. The results<br />

speak for themselves: AT&S quickly emerged from<br />

the crisis, and is stronger than before.<br />

R&D structure<br />

AT&S has a two-part innovation process: our development<br />

centre in Leoben-Hinterberg is where<br />

we work on new solutions for materials, processes<br />

and applications. In the second stage, the research<br />

results are optimised for industrial production in<br />

the plants. Because of their size and focus, the facilities<br />

in Shanghai have a special status: in addition<br />

to the work being done on optimising and<br />

industrialising new applications, development<br />

of HDI technology is systematically advanced in<br />

close cooperation with the technology headquarters<br />

in Leoben.<br />

Research network<br />

AT&S’s R&D activities frequently involve some of<br />

our many business partners. Customers generally<br />

inform us of their requirements and their ideas<br />

for future products, but we also devise new techniques<br />

based on future applications we foresee,<br />

such as the embedding of components inside printed<br />

circuit boards. In addition to our own resources,<br />

we use collaborative agreements with research institutions<br />

and suppliers wherever practicable and<br />

necessary. This network of expertise enables us<br />

to master the most complex challenges extremely<br />

effectively.<br />

R&D focuses and selected research projects<br />

Our R&D activities can be grouped into four general<br />

project areas: high-end HDI, Made in Austria,<br />

ECP ® technology, and Photovoltaics.<br />

High-end-HDI<br />

AT&S is pursuing a number of approaches to further<br />

development of high-tech HDI printed circuit<br />

board technologies. Further miniaturisation<br />

requires a special focus on finer track layouts and<br />

reducing the thickness of the printed circuit board.<br />

Parallel efforts involve the development of new<br />

production processes, which are necessary both<br />

in order to manufacture the new products and to<br />

replace old existing processes with newer, more<br />

cost-effective ones.<br />

With the aim of opening up new possibilities in<br />

this area, in the past financial year AT&S decided<br />

to establish a cooperative venture with Panasonic<br />

Electronic Devices Ltd. The main purpose of the<br />

venture is to combine AT&S’s high-end HDI technology<br />

with Panasonic’s ALIVH ® technology. Integrating<br />

and using both technologies in one product<br />

is an additional option for creating the next generation<br />

of printed circuit boards. The new technology<br />

will meet the future requirements of mobile<br />

appliances in full, and has the added advantage<br />

of offering a more environmentally friendly manufacturing<br />

process.<br />

Made in Austria<br />

This area includes a number of projects for the development<br />

and implementation of new production<br />

technologies to make printed circuit board production<br />

both more flexible and more effective. The<br />

aim is also to find ways for the Austrian plants to<br />

produce smaller volumes and more complex products<br />

more simply and profitably.<br />

2.5D technology research project<br />

This technology focuses on incorporating structural<br />

recesses (cavities) into and onto printed<br />

circuit boards, facilitating deeper embedding<br />

of electronic components, and making thinner<br />

PCBs possible. It also makes it possible to produce<br />

rigid-flex PCBs for flex-to-install applications.