You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

SPECIAL FOCUS<br />

The main<br />

production site at<br />

Wallhamn on the Swedish west coast<br />

has access to a deep water quay for<br />

optimum shipping options and there<br />

are around 20 worldwide licensed<br />

production sites.<br />

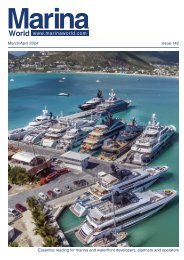

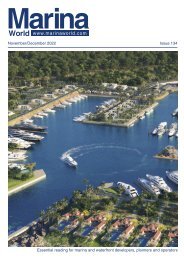

SF systems form the basis of<br />

marinas as diverse as the Russian<br />

hub of Sochi Grande and the idyllic<br />

sanctuary of Tyrell Bay, Grenada. They<br />

dominate strategic sailing routes at<br />

Palmarina Bodrum in Turkey and Linton<br />

Bay <strong>Marina</strong> in Panama. They moor up<br />

superyachts at OneOcean Port Vell in<br />

Spain and Provincetown <strong>Marina</strong> in the<br />

USA, and are cleverly angle jointed to<br />

follow the multiple corners of the fixed<br />

breakwater at Hamilton Princess &<br />

Beach Club, Bermuda.<br />

Floating products<br />

Quality control is strict. Almost all<br />

concrete pontoons and breakwaters<br />

are custom built and often exceed<br />

their 50-year life expectancy and, as<br />

each system comprises modular units,<br />

rebuilds and reconfigurations – as<br />

well as new marinas – are easier to<br />

plan and more cost-effective. Every<br />

marina system or floating solution is<br />

designed using precise calculations<br />

that are based on PIANC guidelines<br />

and national recommendations, and<br />

manufacturing follows Eurocode for<br />

concrete designs.<br />

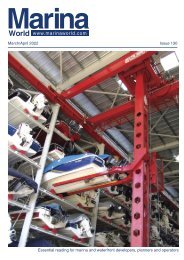

In the 1990s SF hit the<br />

headlines when it installed<br />

a 4m (13ft) - as opposed to<br />

the normal 3m/10ft - wide<br />

breakwater at Mayflower<br />

<strong>Marina</strong> in Plymouth, UK but<br />

today it has the technology<br />

to manufacture breakwater<br />

units up to 10m (33ft) wide.<br />

The key is supreme core<br />

strength, low centre of gravity<br />

and thick layers of quality<br />

concrete, factors which also<br />

apply to its 2.4 to 10m (8 to<br />

33ft) wide range of concrete<br />

pontoons, which are offered in any<br />

length, any angle and any configuration.<br />

Continuing development<br />

Always with an eye to developing new<br />

solutions, SF has looked at alternative<br />

materials and construction methods<br />

over the years. Most recently, it has<br />

patented two new product lines –<br />

ProDock and X-line – which rely on<br />

basalt (volcanic rock) as opposed to<br />

steel for reinforcement. Basalt rebar is<br />

tough, stronger than steel and has a<br />

higher tensile strength.<br />

It is also lighter<br />

in weight making<br />

products easier to<br />

handle and less<br />

expensive to transport.<br />

All projects are<br />

undertaken by means<br />

of SF’s trademarked<br />

SAFE <strong>Marina</strong><br />

System: Secure,<br />

Adapted, Flexible,<br />

Environmentally<br />

friendly. These core<br />

factors owe their<br />

strengths to one hundred years of<br />

knowledge and experience in perfecting<br />

floating concrete systems. By listening<br />

to customers, making thorough site<br />

assessments, delivering eco-friendly<br />

systems that are built to last, and<br />

continuing to perfect and innovate,<br />

chairman Lars Odhe, CEO Michael<br />

Sigvardsson and the international SF<br />

team are more than ready to take the<br />

company into its second century.<br />

www.marinaworld.com - <strong>November</strong>/<strong>December</strong> <strong>2018</strong> 17