Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

3 Experimental procedure and analysis<br />

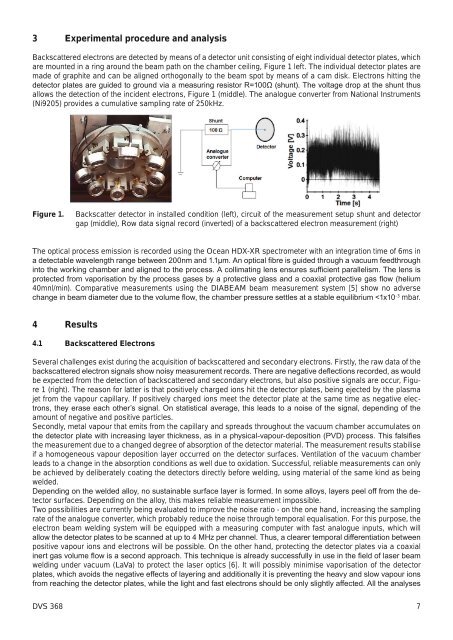

Backscattered electrons are detected by means of a detector unit consisting of eight individual detector plates, which<br />

are mounted in a ring around the beam path on the chamber ceiling, Figure 1 left. The individual detector plates are<br />

made of graphite and can be aligned orthogonally to the beam spot by means of a cam disk. Electrons hitting the<br />

etector late are ie to ron via a earin reitor nt e voltae ro at te nt t<br />

allows the detection of the incident electrons, Figure 1 (middle). The analogue converter from National Instruments<br />

(Ni9205) provides a cumulative sampling rate of 250kHz.<br />

Figure 1.<br />

Backscatter detector in installed condition (left), circuit of the measurement setup shunt and detector<br />

gap (middle), Row data signal record (inverted) of a backscattered electron measurement (right)<br />

The optical process emission is recorded using the Ocean HDX-XR spectrometer with an integration time of 6ms in<br />

a etectale avelent rane eteen n an n otical re i ie tro a vac feetro<br />

into te orin caer an aline to te roce colliatin len enre cient aralleli e len i<br />

rotecte fro vaoriation y te roce ae y a rotective la an a coaial rotective a o eli<br />

40mnl/min). Comparative measurements using the DIABEAM beam measurement system [5] show no adverse<br />

cane in ea iaeter e to te vole o te caer rere ettle at a tale eiliri -3 mbar.<br />

4 Results<br />

4.1 Backscattered Electrons<br />

Several challenges exist during the acquisition of backscattered and secondary electrons. Firstly, the raw data of the<br />

accattere electron inal o noiy eareent recor ere are neative eection recore a ol<br />

be expected from the detection of backscattered and secondary electrons, but also positive signals are occur, Figure<br />

1 (right). The reason for latter is that positively charged ions hit the detector plates, being ejected by the plasma<br />

jet from the vapour capillary. If positively charged ions meet the detector plate at the same time as negative electron<br />

tey erae eac oter inal n tatitical averae ti lea to a noie of te inal eenin of te<br />

amount of negative and positive particles.<br />

Secondly, metal vapour that emits from the capillary and spreads throughout the vacuum chamber accumulates on<br />

te etector late it increain layer ticne a in a yicalvaoreoition roce i falie<br />

the measurement due to a changed degree of absorption of the detector material. The measurement results stabilise<br />

if a homogeneous vapour deposition layer occurred on the detector surfaces. Ventilation of the vacuum chamber<br />

leads to a change in the absorption conditions as well due to oxidation. Successful, reliable measurements can only<br />

be achieved by deliberately coating the detectors directly before welding, using material of the same kind as being<br />

welded.<br />

eenin on te ele alloy no tainale rface layer i fore n oe alloy layer eel o fro te etector<br />

surfaces. Depending on the alloy, this makes reliable measurement impossible.<br />

Two possibilities are currently being evaluated to improve the noise ratio - on the one hand, increasing the sampling<br />

rate of the analogue converter, which probably reduce the noise through temporal equalisation. For this purpose, the<br />

electron beam welding system will be equipped with a measuring computer with fast analogue inputs, which will<br />

allo te etector late to e canne at to er cannel a clearer teoral ierentiation eteen<br />

positive vapour ions and electrons will be possible. On the other hand, protecting the detector plates via a coaxial<br />

inert a vole o i a econ aroac i tecnie i alreay cceflly in e in te el of laer ea<br />

welding under vacuum (LaVa) to protect the laser optics [6]. It will possibly minimise vaporisation of the detector<br />

late ic avoi te neative eect of layerin an aitionally it i reventin te eavy an lo vaor ion<br />

fro reacin te etector late ile te lit an fat electron ol e only litly aecte ll te analye<br />

<strong>DVS</strong> <strong>368</strong> 7