vgbe energy journal 5 (2022) - International Journal for Generation and Storage of Electricity and Heat

vgbe energy journal - International Journal for Generation and Storage of Electricity and Heat. Issue 5 (2022). Technical Journal of the vgbe energy e.V. - Energy is us! NOTICE: Please feel free to read this free copy of the vgbe energy journal. This is our temporary contribution to support experience exchange in the energy industry during Corona times. The printed edition, subscription as well as further services are available on our website, www.vgbe.energy +++++++++++++++++++++++++++++++++++++++++++++++++++++++ Christopher Weßelmann: Editorial Nuclear power in numbers 2021/2022 Kernenergie in Zahlen 2021/2022 Peter Schluppkothen and Mats-Milan L. Müller: How the digital project twin changes plant engineering in power industry Der Digital Project Twin revolutioniert den Anlagenbau in der Energiewirtschaft Stefan Loubichi: Cyberwar in the energy industry: The current status Cyberwar in der Energiewirtschaft: der aktuelle Stand Antonio Ballesteros Avila and Miguel Peinador Veira: Operating experience from ageing events occurred at nuclear power plants Betriebserfahrungen mit Ereignissen in Bezug auf die Betriebszeit von Kernkraftwerken Minhee Kim, Junkyu Song and Kyungho Nam: Assessment of loss of shutdown cooling system accident during mid-loop operation in LSTF experiment using SPACE Code Bewertung des Ausfalls des Nachkühlsystems während des Mitte-Loop-Betriebs im LSTF-Experiment unter Verwendung des SPACE-Codes Jürgen Knorr and Albert Kerber: TRIPLE C waste container for increased long-term safety of HHGW disposal in salt, clay and crystalline TRIPLE C Abfallbehälter zur Erhöhung der Langzeitsicherheit der Einlagerung radioaktiver Abfälle in Salz, Ton und Kristallin Editorial: Nuclear power plants worldwide: Compact statistic 2021 Kernkraftwerke weltweit: Schnellstatistik 2021 vgbe energy: Operating experience with nuclear power plants 2021 Betriebserfahrungen mit Kernkraftwerken 2021 Paul Baruya: Power and coal prospects in developing Africa Trends der Stromerzeugung und des Kohleeinsatzes in den Entwicklungsländern Afrikas

vgbe energy journal - International Journal for Generation and Storage of Electricity and Heat.

Issue 5 (2022).

Technical Journal of the vgbe energy e.V. - Energy is us!

NOTICE: Please feel free to read this free copy of the vgbe energy journal. This is our temporary contribution to support experience exchange in the energy industry during Corona times. The printed edition, subscription as well as further services are available on our website, www.vgbe.energy

+++++++++++++++++++++++++++++++++++++++++++++++++++++++

Christopher Weßelmann: Editorial

Nuclear power in numbers 2021/2022

Kernenergie in Zahlen 2021/2022

Peter Schluppkothen and Mats-Milan L. Müller:

How the digital project twin changes plant engineering in power industry

Der Digital Project Twin revolutioniert den Anlagenbau in der Energiewirtschaft

Stefan Loubichi:

Cyberwar in the energy industry: The current status

Cyberwar in der Energiewirtschaft: der aktuelle Stand

Antonio Ballesteros Avila and Miguel Peinador Veira:

Operating experience from ageing events occurred at nuclear power plants

Betriebserfahrungen mit Ereignissen in Bezug auf die Betriebszeit von Kernkraftwerken

Minhee Kim, Junkyu Song and Kyungho Nam:

Assessment of loss of shutdown cooling system accident during mid-loop operation in LSTF experiment using SPACE Code

Bewertung des Ausfalls des Nachkühlsystems während des Mitte-Loop-Betriebs im LSTF-Experiment unter Verwendung des SPACE-Codes

Jürgen Knorr and Albert Kerber:

TRIPLE C waste container for increased long-term safety of HHGW disposal in salt, clay and crystalline

TRIPLE C Abfallbehälter zur Erhöhung der Langzeitsicherheit der Einlagerung radioaktiver Abfälle in Salz, Ton und Kristallin

Editorial:

Nuclear power plants worldwide: Compact statistic 2021

Kernkraftwerke weltweit: Schnellstatistik 2021

vgbe energy:

Operating experience with nuclear power plants 2021

Betriebserfahrungen mit Kernkraftwerken 2021

Paul Baruya:

Power and coal prospects in developing Africa

Trends der Stromerzeugung und des Kohleeinsatzes in den Entwicklungsländern Afrikas

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Operating experience from ageing events occurred at nuclear power plants<br />

Unknown<br />

Other<br />

Chemical ageing<br />

Creep<br />

Electrical ageing<br />

Erosion<br />

Wear<br />

Corrosion<br />

Irradiation damage<br />

Thermal ageing<br />

Fatigue<br />

Relaxation<br />

Swelling<br />

1<br />

1<br />

Lessons learned<br />

1<br />

The extraction <strong>of</strong> the lessons learned from<br />

the operating experience has been completed<br />

in two steps. First (step 1), low level lessons<br />

learned were retrieved from the IRS<br />

database, or developed in some cases, <strong>for</strong> a<br />

large number <strong>of</strong> the 113 analysed events. A<br />

total <strong>of</strong> 110 low level lessons learned were<br />

obtained. They are given, together with a<br />

short summary <strong>of</strong> the events, in Annex 2 <strong>of</strong><br />

reference [ Ballesteros Avila A., 2019]. Several<br />

lessons are allocated to the same event<br />

in many cases. These low level lessons<br />

learned are very specific, so that they would<br />

2<br />

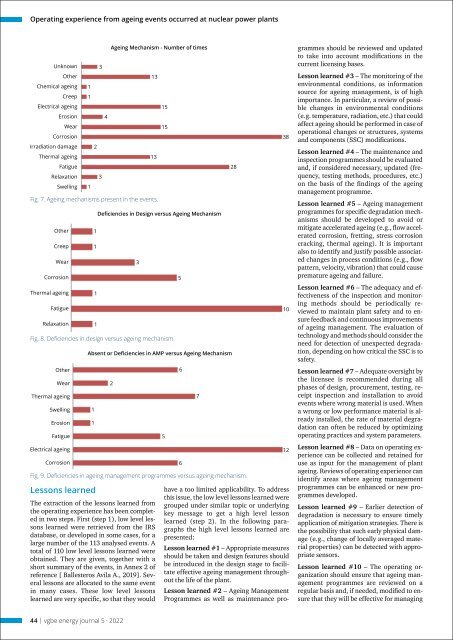

Fig. 7. Ageing mechanisms present in the events.<br />

Other<br />

Creep<br />

Wear<br />

Corrosion<br />

Thermal ageing<br />

Fatigue<br />

Relaxation<br />

1<br />

1<br />

1<br />

1<br />

3<br />

3<br />

4<br />

Ageing Mechanism - Number <strong>of</strong> times<br />

13<br />

13<br />

Deficiencies in Design versus Ageing Mechanism<br />

Fig. 8. Deficiencies in design versus ageing mechanism.<br />

Other<br />

Wear<br />

Thermal ageing<br />

Swelling<br />

Erosion<br />

Fatigue<br />

Electrical ageing<br />

Corrosion<br />

3<br />

Absent or Deficiencies in AMP versus Ageing Mechanism<br />

1<br />

1<br />

2<br />

Fig. 9. Deficiencies in ageing management programmes versus ageing mechanism.<br />

15<br />

15<br />

5<br />

5<br />

6<br />

6<br />

7<br />

28<br />

38<br />

10<br />

12<br />

have a too limited applicability. To address<br />

this issue, the low level lessons learned were<br />

grouped under similar topic or underlying<br />

key message to get a high level lesson<br />

learned (step 2). In the following paragraphs<br />

the high level lessons learned are<br />

presented:<br />

Lesson learned #1 – Appropriate measures<br />

should be taken <strong>and</strong> design features should<br />

be introduced in the design stage to facilitate<br />

effective ageing management throughout<br />

the life <strong>of</strong> the plant.<br />

Lesson learned #2 – Ageing Management<br />

Programmes as well as maintenance programmes<br />

should be reviewed <strong>and</strong> updated<br />

to take into account modifications in the<br />

current licensing bases.<br />

Lesson learned #3 – The monitoring <strong>of</strong> the<br />

environmental conditions, as in<strong>for</strong>mation<br />

source <strong>for</strong> ageing management, is <strong>of</strong> high<br />

importance. In particular, a review <strong>of</strong> possible<br />

changes in environmental conditions<br />

(e.g. temperature, radiation, etc.) that could<br />

affect ageing should be per<strong>for</strong>med in case <strong>of</strong><br />

operational changes or structures, systems<br />

<strong>and</strong> components (SSC) modifications.<br />

Lesson learned #4 – The maintenance <strong>and</strong><br />

inspection programmes should be evaluated<br />

<strong>and</strong>, if considered necessary, updated (frequency,<br />

testing methods, procedures, etc.)<br />

on the basis <strong>of</strong> the findings <strong>of</strong> the ageing<br />

management programme.<br />

Lesson learned #5 – Ageing management<br />

programmes <strong>for</strong> specific degradation mechanisms<br />

should be developed to avoid or<br />

mitigate accelerated ageing (e.g., flow accelerated<br />

corrosion, fretting, stress corrosion<br />

cracking, thermal ageing). It is important<br />

also to identify <strong>and</strong> justify possible associated<br />

changes in process conditions (e.g., flow<br />

pattern, velocity, vibration) that could cause<br />

premature ageing <strong>and</strong> failure.<br />

Lesson learned #6 – The adequacy <strong>and</strong> effectiveness<br />

<strong>of</strong> the inspection <strong>and</strong> monitoring<br />

methods should be periodically reviewed<br />

to maintain plant safety <strong>and</strong> to ensure<br />

feedback <strong>and</strong> continuous improvements<br />

<strong>of</strong> ageing management. The evaluation <strong>of</strong><br />

technology <strong>and</strong> methods should consider the<br />

need <strong>for</strong> detection <strong>of</strong> unexpected degradation,<br />

depending on how critical the SSC is to<br />

safety.<br />

Lesson learned #7 – Adequate oversight by<br />

the licensee is recommended during all<br />

phases <strong>of</strong> design, procurement, testing, receipt<br />

inspection <strong>and</strong> installation to avoid<br />

events where wrong material is used. When<br />

a wrong or low per<strong>for</strong>mance material is already<br />

installed, the rate <strong>of</strong> material degradation<br />

can <strong>of</strong>ten be reduced by optimizing<br />

operating practices <strong>and</strong> system parameters.<br />

Lesson learned #8 – Data on operating experience<br />

can be collected <strong>and</strong> retained <strong>for</strong><br />

use as input <strong>for</strong> the management <strong>of</strong> plant<br />

ageing. Reviews <strong>of</strong> operating experience can<br />

identify areas where ageing management<br />

programmes can be enhanced or new programmes<br />

developed.<br />

Lesson learned #9 – Earlier detection <strong>of</strong><br />

degradation is necessary to ensure timely<br />

application <strong>of</strong> mitigation strategies. There is<br />

the possibility that such early physical damage<br />

(e.g., change <strong>of</strong> locally averaged material<br />

properties) can be detected with appropriate<br />

sensors.<br />

Lesson learned #10 – The operating organization<br />

should ensure that ageing management<br />

programmes are reviewed on a<br />

regular basis <strong>and</strong>, if needed, modified to ensure<br />

that they will be effective <strong>for</strong> managing<br />

44 | <strong>vgbe</strong> <strong>energy</strong> <strong>journal</strong> 5 · <strong>2022</strong>