Issue 60

The UK's outdoor hospitality business magazine for function venues, glamping, festivals and outdoor events

The UK's outdoor hospitality business magazine for function venues, glamping, festivals and outdoor events

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

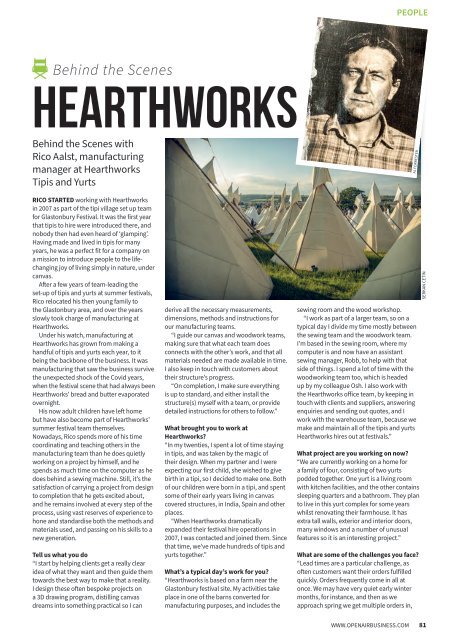

PEOPLE<br />

Behind the Scenes<br />

Hearthworks<br />

Behind the Scenes with<br />

Rico Aalst, manufacturing<br />

manager at Hearthworks<br />

Tipis and Yurts<br />

AL FORRESTER<br />

RICO STARTED working with Hearthworks<br />

in 2007 as part of the tipi village set up team<br />

for Glastonbury Festival. It was the first year<br />

that tipis to hire were introduced there, and<br />

nobody then had even heard of ‘glamping’.<br />

Having made and lived in tipis for many<br />

years, he was a perfect fit for a company on<br />

a mission to introduce people to the lifechanging<br />

joy of living simply in nature, under<br />

canvas.<br />

After a few years of team-leading the<br />

set-up of tipis and yurts at summer festivals,<br />

Rico relocated his then young family to<br />

the Glastonbury area, and over the years<br />

slowly took charge of manufacturing at<br />

Hearthworks.<br />

Under his watch, manufacturing at<br />

Hearthworks has grown from making a<br />

handful of tipis and yurts each year, to it<br />

being the backbone of the business. It was<br />

manufacturing that saw the business survive<br />

the unexpected shock of the Covid years,<br />

when the festival scene that had always been<br />

Hearthworks’ bread and butter evaporated<br />

overnight.<br />

His now adult children have left home<br />

but have also become part of Hearthworks’<br />

summer festival team themselves.<br />

Nowadays, Rico spends more of his time<br />

coordinating and teaching others in the<br />

manufacturing team than he does quietly<br />

working on a project by himself, and he<br />

spends as much time on the computer as he<br />

does behind a sewing machine. Still, it’s the<br />

satisfaction of carrying a project from design<br />

to completion that he gets excited about,<br />

and he remains involved at every step of the<br />

process, using vast reserves of experience to<br />

hone and standardise both the methods and<br />

materials used, and passing on his skills to a<br />

new generation.<br />

Tell us what you do<br />

“I start by helping clients get a really clear<br />

idea of what they want and then guide them<br />

towards the best way to make that a reality.<br />

I design these often bespoke projects on<br />

a 3D drawing program, distilling canvas<br />

dreams into something practical so I can<br />

derive all the necessary measurements,<br />

dimensions, methods and instructions for<br />

our manufacturing teams.<br />

“I guide our canvas and woodwork teams,<br />

making sure that what each team does<br />

connects with the other’s work, and that all<br />

materials needed are made available in time.<br />

I also keep in touch with customers about<br />

their structure’s progress.<br />

“On completion, I make sure everything<br />

is up to standard, and either install the<br />

structure(s) myself with a team, or provide<br />

detailed instructions for others to follow.”<br />

What brought you to work at<br />

Hearthworks?<br />

“In my twenties, I spent a lot of time staying<br />

in tipis, and was taken by the magic of<br />

their design. When my partner and I were<br />

expecting our first child, she wished to give<br />

birth in a tipi, so I decided to make one. Both<br />

of our children were born in a tipi, and spent<br />

some of their early years living in canvas<br />

covered structures, in India, Spain and other<br />

places.<br />

“When Hearthworks dramatically<br />

expanded their festival hire operations in<br />

2007, I was contacted and joined them. Since<br />

that time, we’ve made hundreds of tipis and<br />

yurts together.”<br />

What’s a typical day’s work for you?<br />

“Hearthworks is based on a farm near the<br />

Glastonbury festival site. My activities take<br />

place in one of the barns converted for<br />

manufacturing purposes, and includes the<br />

sewing room and the wood workshop.<br />

“I work as part of a larger team, so on a<br />

typical day I divide my time mostly between<br />

the sewing team and the woodwork team.<br />

I’m based in the sewing room, where my<br />

computer is and now have an assistant<br />

sewing manager, Robb, to help with that<br />

side of things. I spend a lot of time with the<br />

woodworking team too, which is headed<br />

up by my colleague Osh. I also work with<br />

the Hearthworks office team, by keeping in<br />

touch with clients and suppliers, answering<br />

enquiries and sending out quotes, and I<br />

work with the warehouse team, because we<br />

make and maintain all of the tipis and yurts<br />

Hearthworks hires out at festivals.”<br />

What project are you working on now?<br />

“We are currently working on a home for<br />

a family of four, consisting of two yurts<br />

podded together. One yurt is a living room<br />

with kitchen facilities, and the other contains<br />

sleeping quarters and a bathroom. They plan<br />

to live in this yurt complex for some years<br />

whilst renovating their farmhouse. It has<br />

extra tall walls, exterior and interior doors,<br />

many windows and a number of unusual<br />

features so it is an interesting project.”<br />

What are some of the challenges you face?<br />

“Lead times are a particular challenge, as<br />

often customers want their orders fulfilled<br />

quickly. Orders frequently come in all at<br />

once. We may have very quiet early winter<br />

months, for instance, and then as we<br />

approach spring we get multiple orders in,<br />

SERKAN CETIN<br />

WWW.OPENAIRBUSINESS.COM 81