petfoodpro 3/2023

PetFood PRO is the international magazine for executives and specialists in the manufacture of food for domestic animals – the pet food industry. The magazine focuses on food and delicacies for dogs, cats and other small animals, ornamental birds and fish, as well as animals kept in terrariums. We publish feature articles, reports and announcements about new ingredients, technology, equipment and processes, packaging machinery and materials as well as marketing trends and developments. Readers are executives, product developers and specialists in the pet food industry, including process and packaging engineers. PetFood PRO will be published in English. Circulation is worldwide, with an emphasis on important growth markets.

PetFood PRO is the international magazine for executives and specialists in the manufacture of food for domestic animals – the pet food industry. The magazine focuses on food and delicacies for dogs, cats and other small animals, ornamental birds and fish, as well as animals kept in terrariums.

We publish feature articles, reports and announcements about new ingredients, technology, equipment and processes, packaging machinery and materials as well as marketing trends and developments. Readers are executives, product developers and specialists in the pet food industry, including process and packaging engineers. PetFood PRO will be published in English. Circulation is worldwide, with an emphasis on important growth markets.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

PACKAGING<br />

After weighing, product is transferred<br />

to the pouch filling and sealing system.<br />

Packs are then passed through the<br />

Ishida DAGS-G-S015 checkweigher and<br />

metal detector combination to ensure<br />

product is the correct weight and free of<br />

metal contaminants. The checkweigher<br />

incorporates Ishida’s Anti-Floor Vibration<br />

(AFV) technology to maintain high<br />

weighing accuracy in environments<br />

susceptible to floor vibration. It also<br />

features the company’s Retail Reject<br />

Confirmation (RRC) software that checks<br />

and confirms that out-of-spec products<br />

or packs have been successfully removed<br />

from the line.<br />

“We have enjoyed a longstanding working<br />

partnership with Ishida,” commented<br />

Patricia Molloy, Marketing Manager of SF<br />

Engineering. “The company’s equipment<br />

is the best on the market, particularly<br />

in terms of its efficiency and reliability,<br />

and the CCW-RVE and DACS-G were the<br />

perfect choices to ensure we could deliver<br />

our targets for the line.”<br />

The new line has increased throughput<br />

by 75 percent. Operator requirement has<br />

been reduced by 60 percent and personnel<br />

reallocated to other manufacturing<br />

processes, thus improving overall facility<br />

productivity. These benefits have led to<br />

a reduced cost per pack, with Irish Dog<br />

Foods achieving a return on investment<br />

within 12 months of installation.<br />

“The line has been working well against<br />

agreed targets and is helping with<br />

our plans for further expansion and<br />

automation,” said Andrew Flynn, Irish Dog<br />

Foods’ Factory Manager. “The solution<br />

that SF Engineering and Ishida have<br />

delivered really is impressive.”<br />

For more information<br />

www.ishidaeurope.com<br />

Robotic Technology Answers<br />

Multiple Needs for PetFood<br />

a way to orient and load them was very<br />

important to the customer. With their<br />

robots, Cama was able to successfully<br />

orient the cups so they are all facing the<br />

same direction, with graphics aligned and<br />

in easy view on store shelves.<br />

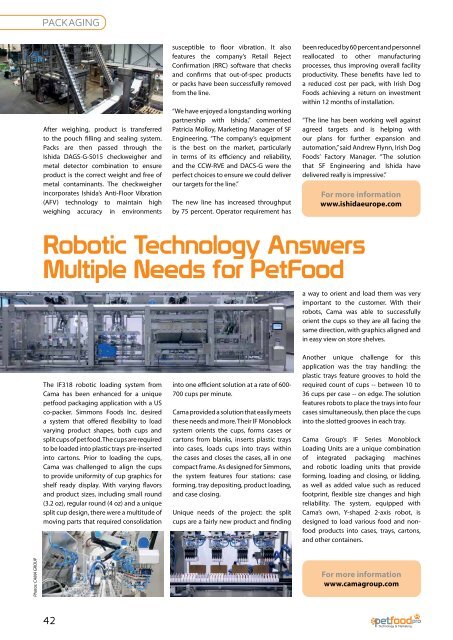

The IF318 robotic loading system from<br />

Cama has been enhanced for a unique<br />

petfood packaging application with a US<br />

co-packer. Simmons Foods Inc. desired<br />

a system that offered flexibility to load<br />

varying product shapes, both cups and<br />

split cups of pet food. The cups are required<br />

to be loaded into plastic trays pre-inserted<br />

into cartons. Prior to loading the cups,<br />

Cama was challenged to align the cups<br />

to provide uniformity of cup graphics for<br />

shelf ready display. With varying flavors<br />

and product sizes, including small round<br />

(3.2 oz), regular round (4 oz) and a unique<br />

split cup design, there were a multitude of<br />

moving parts that required consolidation<br />

into one efficient solution at a rate of 600-<br />

700 cups per minute.<br />

Cama provided a solution that easily meets<br />

these needs and more. Their IF Monoblock<br />

system orients the cups, forms cases or<br />

cartons from blanks, inserts plastic trays<br />

into cases, loads cups into trays within<br />

the cases and closes the cases, all in one<br />

compact frame. As designed for Simmons,<br />

the system features four stations: case<br />

forming, tray depositing, product loading,<br />

and case closing.<br />

Unique needs of the project: the split<br />

cups are a fairly new product and finding<br />

Another unique challenge for this<br />

application was the tray handling: the<br />

plastic trays feature grooves to hold the<br />

required count of cups -- between 10 to<br />

36 cups per case -- on edge. The solution<br />

features robots to place the trays into four<br />

cases simultaneously, then place the cups<br />

into the slotted grooves in each tray.<br />

Cama Group’s IF Series Monoblock<br />

Loading Units are a unique combination<br />

of integrated packaging machines<br />

and robotic loading units that provide<br />

forming, loading and closing, or lidding,<br />

as well as added value such as reduced<br />

footprint, flexible size changes and high<br />

reliability. The system, equipped with<br />

Cama’s own, Y-shaped 2-axis robot, is<br />

designed to load various food and nonfood<br />

products into cases, trays, cartons,<br />

and other containers.<br />

Photos: CAMA GROUP<br />

For more information<br />

www.camagroup.com<br />

42<br />

Technology & Marketing