petfoodpro 3/2023

PetFood PRO is the international magazine for executives and specialists in the manufacture of food for domestic animals – the pet food industry. The magazine focuses on food and delicacies for dogs, cats and other small animals, ornamental birds and fish, as well as animals kept in terrariums. We publish feature articles, reports and announcements about new ingredients, technology, equipment and processes, packaging machinery and materials as well as marketing trends and developments. Readers are executives, product developers and specialists in the pet food industry, including process and packaging engineers. PetFood PRO will be published in English. Circulation is worldwide, with an emphasis on important growth markets.

PetFood PRO is the international magazine for executives and specialists in the manufacture of food for domestic animals – the pet food industry. The magazine focuses on food and delicacies for dogs, cats and other small animals, ornamental birds and fish, as well as animals kept in terrariums.

We publish feature articles, reports and announcements about new ingredients, technology, equipment and processes, packaging machinery and materials as well as marketing trends and developments. Readers are executives, product developers and specialists in the pet food industry, including process and packaging engineers. PetFood PRO will be published in English. Circulation is worldwide, with an emphasis on important growth markets.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

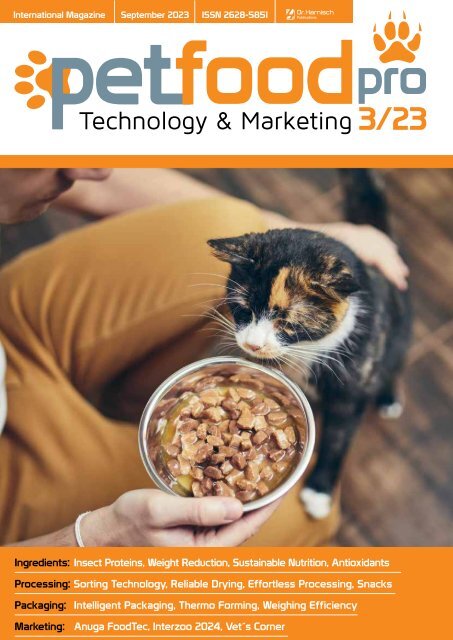

International Magazine September <strong>2023</strong> ISSN 2628-5851<br />

Technology & Marketing 3/23<br />

Ingredients: Insect Proteins, Weight Reduction, Sustainable Nutrition, Antioxidants<br />

Processing: Sorting Technology, Reliable Drying, Effortless Processing, Snacks<br />

Packaging: Intelligent Packaging, Thermo Forming, Weighing Efficiency<br />

Marketing: Anuga FoodTec, Interzoo 2024, Vet´s Corner

Prof. Visscher from the University of<br />

Veterinary Medicine Hannover and top<br />

speakers from the industry<br />

Factory tour of the most modern insect<br />

facility in Germany<br />

Exchange with producers of insect<br />

protein and tat<br />

Gala Dinner & Networking Event<br />

Organized and hosted by<br />

()<br />

FARMINSECT<br />

Largest producer of regional<br />

and sustainable insects<br />

X<br />

(u)<br />

greclo<br />

Leading processor<br />

ofinsects

EDITORIAL<br />

Discovering Cats<br />

My wife has been adopted. It came as<br />

rather a surprise, but the whole family<br />

is delighted. There’s a lot of truth in the<br />

saying that cats choose their hosts, rather<br />

than the other way around, as with other<br />

pets. The interesting thing is that my wife<br />

didn’t actually want a pet at the moment,<br />

and certainly not a cat, after having been<br />

bitten as a child.<br />

It came about when our next-door<br />

neighbours moved and the new catloving<br />

neighbours accepted an additional<br />

responsibility. During the upheaval we had<br />

a visitor, who was looking for a peaceful<br />

corner. As we stroked her and gave her a<br />

little snack, as you do, she decided to stay<br />

for a while. My wife found the purring and<br />

stroking very peaceful herself and one<br />

thing led to another. During our vacation<br />

we spent a lot of time in the garden, the<br />

three of us, and found it very relaxing.<br />

As a child I lived on a farm, so I knew<br />

more about working dogs, as well as<br />

cows, geese and horses before starting<br />

this magazine. Cats were there to catch<br />

mice. Since this summer I have learned<br />

more about domestic cats. “Our“ cat<br />

(who prefers not to be named to keep<br />

her reputation intact) does give a lot of<br />

love, it’s true. She also looks for food,<br />

water, snacks and a bed for the day-time<br />

rests. She is also aware of her territory and<br />

defends it fiercely. This mostly happens<br />

at dawn or dusk and is loudest when we<br />

have just gone to sleep.<br />

The new neighbours (and official owners<br />

of the cat) report that she comes to eat<br />

and socialise every day, but they are<br />

happy if she is sharing herself around. We<br />

have spent time discovering what the pet<br />

food industry has been putting together<br />

to keep these special animals content.<br />

We were surprised at how many different<br />

kinds of food there is, wet and dry, for<br />

adults, juniors and seniors. And how many<br />

toys! We spent a long time in one or two<br />

stores and took home a small selection.<br />

A cat‘s traits include its small size, social<br />

nature, obvious body language, love of<br />

play, and high intelligence. It is fascinating<br />

Ian D. Healey, Editor-in-Chief<br />

and somehow bewitching to observe<br />

and be a part of. Having accepted one<br />

cat into the extended family, we then<br />

found they often visit each other! Our<br />

garden has become a meeting place and<br />

entertainment centre and we are richer<br />

because of it.<br />

Never a dull moment!<br />

Sincerely<br />

If you like it subscribe!<br />

Issue 3 <strong>2023</strong><br />

3

CONTENTS<br />

International Magazine September <strong>2023</strong> ISSN 2628-5851<br />

Technology & Marketing 3/23<br />

Ingredients: Insect Proteins, Weight Reduction, Sustainable Nutrition, Antioxidants<br />

Processing: Sorting Technology, Reliable Drying, Effortless Processing, Snacks<br />

Packaging: Intelligent Packaging, Thermo Forming, Weighing Efficiency<br />

Marketing: Anuga FoodTec, Interzoo 2024, Vet´s Corner<br />

Issue 3 September <strong>2023</strong><br />

Shifting consumer expectations make it more important now than ever before<br />

for processors and renderers to have effective safeguards in place, to protect<br />

food safety and product quality, whilst also minimizing food waste to improve<br />

sustainability and profitability. These things have always mattered, of course, but<br />

thanks to technical advances of modern sorting machines, there are solutions to<br />

all of these challenges.<br />

The Cover Story starts on page 6<br />

Cover: TOMRA Food<br />

Ingredients<br />

Processing<br />

6 Spotlight on Protein Sorting<br />

10 Tereos Launches Profeed ADVANCED®, a Complementary<br />

Feed to Support Dogs’ Immune Function<br />

11 Low Glycaemic Properties of Isomaltulose Confirmed in Dogs<br />

14 High-quality, Functional, and Sustainable: the Current<br />

Trends in Natural Dog Nutrition<br />

18 Protection of Pet Food with Natural and Cost-effective<br />

Antioxidants Solutions<br />

21 Insects in Pet Food: Do Insect Larvae Outcompete Classic<br />

Protein Sources?<br />

23 Nutrition Brand Evolution with Nuvin<br />

24 Efficient Process Technology for Dogs and Cats<br />

26 Technology for Pet Food Snacks and Treats<br />

28 Energy-saving and Reliable Drying of Cat Food<br />

31 New Concept Revolutionizes Animal Feed Production<br />

35 Deadly Mycotoxins in Pet Food Cost Pet Health and Brand<br />

Trust: There is an Answer<br />

36 Sustainability in Pet Food Production? Important Steps and<br />

Solutions!<br />

Just as human diets are different, so are those of our pets: True<br />

to the motto "what's good for me can't be bad for my dog",<br />

owners (often unconsciously) adapt their pet's diet to their own.<br />

Preferably fresh and natural ingredients find their way into the<br />

bowl – with a demand for quality and positive health effects.<br />

The nutritional spectrum is wide ranging. Take a look at our<br />

analysis on page 14.<br />

Industrial machines are a major investment in which sustainability<br />

plays a key role. Production line components are expected<br />

to process tens of thousands of tonnes of raw materials for many<br />

years. The animal feed market is growing and producers need to<br />

keep pace. A German company has just made such an investment<br />

and relies on two automatic industrial grinders, which take high<br />

processing volumes in their stride. See page 31<br />

4<br />

Technology & Marketing

Departments<br />

3 Editorial<br />

52 Upcoming Events<br />

52 Impressum<br />

Events / Marketing<br />

46 Young and Innovative: Interzoo 2024 Encouraging Start-ups<br />

47 We Mourn the Loss of our Friend and Partner<br />

48 Interview with Dr. Gilch, specialist veterinary practice<br />

50 Premiere of the Pet Food Zone at Anuga FoodTec 2024<br />

Your Recipe.<br />

Automated to Perfection.<br />

Food-focused. Global resources<br />

that deliver.<br />

Whether it’s storing, sifting, metering,<br />

weighing or transferring, Shick Esteve<br />

is your complete ingredient automation<br />

systems provider.<br />

Packaging<br />

38 Sustainable Packaging for Dry Pet Food<br />

41 Weighing Technology Helps Petfood Line Efficiency<br />

42 Robotic Technology Answers Multiple Needs for PetFood<br />

43 Coveris Expands Pet-Food Business With a Further<br />

Acquisition in CEE.<br />

44 Pet Food Packaged in an Efficient, Resource-saving and<br />

Eye-catching Way<br />

A significant category in pet food is snacks, such as dog or<br />

cat treats. In this competitive sector, pet food manufacturers<br />

must be able to adapt quickly to the latest trends, so that they<br />

can always meet the current customer needs. Here, packaging<br />

plays a key role, where high performance traysealers and<br />

thermoformers and the development of innovative packaging<br />

concepts can provide support. Full details on page 44.<br />

shickesteve.com/fr | +33 (0)2 48 66 60 60<br />

Issue 3 <strong>2023</strong><br />

5

COVER STORY<br />

Spotlight on Protein Sorting<br />

Maximizing protein´s profitability from meat, poultry, rendering and pet food<br />

Producing and selling tasty, protein-rich petfood shouldn’t be compromised. TOMRA's equipment helps prevent unwanted foreign<br />

materials. Photos: TOMRA Food<br />

There’s money in protein. Whether<br />

it’s meat or poultry, and whether it’s<br />

processed for human consumption or<br />

rendered for pet food, it’s worth making<br />

the effort to extract every possible<br />

kilogram of saleable raw materials. But<br />

this is a business with risks.<br />

For one thing, derived meat for rendering<br />

delivered by slaughterhouses typically<br />

contains foreign materials, and these can<br />

be so difficult to detect that they get all<br />

the way down the processing line into the<br />

final product. For another, when rendered<br />

meat and poultry are turned into dry<br />

pet food, one type of kibble can easily<br />

get cross-contaminated with another,<br />

so that packages mistakenly contain<br />

unlisted ingredients. And if potentially<br />

harmful products get into the hands of an<br />

unhappy customer with a cellphone and<br />

social media access, the retailer’s brand<br />

reputation can quickly be damaged.<br />

These threats mean it is crucial for<br />

processors and renderers to have<br />

effective safeguards in place to protect<br />

food safety and product quality, whilst<br />

also minimizing food waste to improve<br />

sustainability and profitability. These<br />

things have always mattered, of course,<br />

but shifting consumer expectations make<br />

them more important now than ever<br />

before.<br />

Risks, yes - but potentially big<br />

rewards<br />

The risks and rewards of meat processing<br />

and rendering are increasing for two<br />

big reasons. One is that consumers have<br />

become far less tolerant of imperfections<br />

in the food they buy for themselves or<br />

their pets. The other is that the demand<br />

for high-quality, protein-rich foods for<br />

people and pets is growing fast.<br />

In fact, mankind’s need for proteins is<br />

set to skyrocket. The United Nations’<br />

Food and Agriculture Division predicts<br />

that by 2050 global meat production<br />

will double - yes, double! - as the world’s<br />

population increases from 7.9 billion<br />

people to 9.8 billion. At the same time,<br />

increasing wealth in developing nations<br />

will empower greater numbers of people<br />

to spend more on food.<br />

Demand for pet food is also booming.<br />

Market researchers forecast that this<br />

market’s global value will increase in the<br />

next seven years at a compound annual<br />

growth rate of almost five percent, from<br />

$94bn in 2020 to $137bn in 2028. What’s<br />

more, this market is being reshaped<br />

by the ‘humanization’ of products that<br />

contain fresh ingredients, superfoods,<br />

and high protein - and premium products<br />

can command premium prices.<br />

Increasing meat production is good news<br />

for processors and renderers, but there is a<br />

downside: meat and dairy production are<br />

responsible for a whopping 14% of global<br />

greenhouse gas emissions. This means it’s<br />

imperative to minimize food waste - not<br />

only by getting retailers and consumers<br />

into the habit of throwing away less, but<br />

also by making more efficient use of the<br />

potentially usable food in livestock.<br />

For these reasons, rendering is an<br />

environmentally-friendly way to recycle<br />

material that would otherwise be wasted<br />

- and it also reduces the greenhouse<br />

gas emissions that would come from<br />

6<br />

Technology & Marketing

COVER STORY<br />

the natural decomposition of animal<br />

parts in compost or landfill. The National<br />

Renderers Association in the USA<br />

calculates that rendering animal tissues<br />

rather than leaving them to decompose<br />

has the same effect on greenhouse gas<br />

emissions as removing 12.2 million cars<br />

from the road.<br />

Sorting machines solve the<br />

problems<br />

Thanks to technical advances, there<br />

are solutions to all of these challenges.<br />

TOMRA Food, the leading manufacturer of<br />

sensor-based sorters for the food industry,<br />

offers machines that safeguard brand<br />

reputations and enhance sustainability<br />

by reducing food waste, protecting food<br />

safety, and consistently maintaining high<br />

product standards.<br />

The TOMRA 5B safeguards producers and brands against complaints and recalls<br />

Modern optical sorting machines also<br />

solve the widespread problem of labor<br />

scarcity, as well as helping to eliminate<br />

the health risks inherent on processing<br />

lines - as the COVID-19 pandemic drags<br />

on - when people have to spend a long<br />

time standing close to each other. And<br />

whereas manual sorting is subjective,<br />

imperfect, and especially vulnerable<br />

to errors when laborers are tired or<br />

bored, automated sorters work from the<br />

beginning to the end of each shift with<br />

unflagging accuracy.<br />

TOMRA’s sorters detect and eject<br />

unwanted materials from processing<br />

lines that simply cannot be seen by the<br />

human eye or inferior machines. They do<br />

this by inspecting materials according<br />

to their shape, color, structure, size, and<br />

even their biological characteristics.<br />

TOMRA also offers machines with x-ray<br />

technology to detect the presence in<br />

food of high-density foreign materials.<br />

For additional advantages, TOMRA’s<br />

machines can be connected to TOMRA<br />

Insight, a web-based data platform that<br />

gathers sorting data in real-time and<br />

stores this securely in the cloud. Live<br />

data can be reacted to immediately<br />

(and remotely) to optimize machine<br />

settings; historical data can be used<br />

to quantify and compare the quality<br />

of materials from suppliers. Such data<br />

analysis will become increasingly<br />

valuable as we move into a digitized<br />

future, transforming sorting from an<br />

operational process into a strategic<br />

management tool.<br />

So, let’s take a brief look at the sorting<br />

machines best-suited to meat and poultry<br />

processors, rendering plants, and pet food<br />

processors.<br />

Solutions for meat and poultry<br />

TOMRA offers sorting solutions for a wide<br />

variety of meat and poultry applications.<br />

These are for frozen products such as<br />

ground meat, nuggets, patties, and bacon<br />

bits, and for fresh raw products such as<br />

sausages.<br />

TOMRA also offers inline inspection<br />

systems. These help processors determine<br />

the right fat percentage for any grinder/<br />

mixer set-up for minced meat, burgers,<br />

and sausages, as well as making real-time<br />

measurements of protein and moisture<br />

levels. And the QV-P in-line detection<br />

machine for chicken fillets helps ensure<br />

that fillets with ‘wooden breast’ don’t end<br />

up in the final packaging.<br />

Producing and selling tasty, protein-rich<br />

sausages shouldn’t be compromised by<br />

having casing residues still attached to<br />

the final product (or by any other foreign<br />

material, for that matter). The TOMRA<br />

5B safeguards producers and brands<br />

against complaints and expensive recalls<br />

by detecting even the smallest casing<br />

fragments. The TOMRA 5B also controls for<br />

sausage length, dimensions, discoloration,<br />

and breakages. And there’s the option to<br />

sort out the rejects in two streams - one<br />

for foreign materials and casing remains,<br />

and one for products that don’t match the<br />

set scope but can be reused, minimizing<br />

food waste.<br />

For IQF products such as chicken nuggets<br />

or stripes, bacon bits, or other breaded<br />

or un-breaded products, the best sorters<br />

are the TOMRA 5C. Located after the<br />

freezer and close to packaging, this unit<br />

sets the benchmark in product safety<br />

at the same time as minimizing false<br />

rejects and food waste. By using new,<br />

best-in-class laser technology combined<br />

with TOMRA’s unique BSI+ (biometric<br />

signature identification) scanner, the<br />

unseen becomes visible, making foreign<br />

materials a problem of the past. These<br />

technologies are also highly effective at<br />

sorting-out discoloration, black spots,<br />

embedded plastic, doubles, thin coating,<br />

and voids.<br />

Sorters for pet food and<br />

rendering<br />

Producing food for pets is strictly<br />

regulated by local and global legislation<br />

which is designed to ensure product<br />

quality and food safety. Complying with<br />

these regulations requires the use of<br />

safe ingredients and additives, hygienic<br />

processing practices, and HACCP (hazards<br />

analysis and critical control points)<br />

management - but even so, there is still<br />

the risk of foreign materials entering the<br />

manufacturing facility in raw materials.<br />

This is why TOMRA works closely not<br />

only with pet food manufacturers, but<br />

also with their suppliers in the rendering<br />

industry.<br />

Important protein sources in both wet<br />

and dry pet food are animal-derived<br />

ingredients. However, entering the<br />

rendering facilities these ingredients<br />

Issue 3 <strong>2023</strong><br />

7

COVER STORY<br />

the TOMRA 5B is the perfect solution,<br />

ensuring that only the right products get<br />

into the package.<br />

In wet pet food, the TOMRA 5B is ideal<br />

for the inbound set-up, where incoming<br />

frozen blocks pass through either a breaker<br />

or a grinder before entering the mixer.<br />

Placed between the breaker/grinder and<br />

mixer, the TOMRA 5B effectively detects<br />

and sorts various foreign materials<br />

including stones, hard and soft plastics,<br />

metal, wood, glass, rubber and bones. In<br />

addition to protecting final products from<br />

unwanted materials, the TOMRA 5B also<br />

logs every batch, so it is possible to assess<br />

what’s coming from suppliers accurately.<br />

The TOMRA 5C sets the benchmark in product safety<br />

often contain various foreign bodies<br />

which come from the abattoirs, such as<br />

rubber parts, foils, wood, glass, and metals.<br />

This is hard to avoid with an automated<br />

production line, but also mostly hard to<br />

detect with conventional methods such<br />

as metal detection and/or X-ray.<br />

The TOMRA 5C solves this, preventing<br />

foreign materials from reaching the pet<br />

food manufacturer. This sorter often acts<br />

as the final control on the meal line: placed<br />

after the final screen, it not only detects<br />

and rejects even the smallest particle<br />

of foreign material but also sources out<br />

all the good product coming from the<br />

screen, feeding this into the good stream<br />

again. These capabilities, plus the ability<br />

to regulate the ash content to enhance<br />

the final quality, make the TOMRA 5C<br />

essential for every meal stream.<br />

In dry pet food, foreign material isn’t the<br />

only threat - there’s also the problem of<br />

cross-contamination. And as a solution,<br />

the TOMRA Nimbus is unbeatable. This<br />

machine’s various sensors protect against<br />

foreign materials, loose and embedded,<br />

and cross-contamination - and with<br />

TOMRA’s new pet food software, the<br />

change over from one recipe to the next<br />

is like a snap of the fingers. This eliminates<br />

traditional ways of trying to avoid crosscontamination<br />

which are both timeconsuming<br />

and product-consuming.<br />

TOMRA’s unique BSI+ technology checks<br />

the inside of materials, ensuring that<br />

different types of kibble don’t get mixed<br />

even if they are near-identical in outward<br />

appearance, and by using the new<br />

petfood software, the operator always has<br />

the best view on what to produce next.<br />

For producing best-in-class pet treats<br />

and snacks, foreign materials must be<br />

prevented from ending up in the final<br />

package, and products should have<br />

the same size, form and color. For this<br />

The accurate removal of foreign bodies such as food bones and meat is critical<br />

An investment that pays back<br />

well<br />

When processors and renderers first<br />

adopt TOMRA’s sorting solutions, they<br />

are pleased to find that the once-steady<br />

trickle of customer complaints dries up.<br />

One good example of this is JG Pears, a<br />

leading processor of animal by-products<br />

and food waste in the UK, producing a<br />

range of meals and fat for the pet food<br />

industry. The company’s Site Manager,<br />

Craig Harrison, said: “Non-conformances<br />

with our customers have reduced<br />

dramatically, and we see very, very little<br />

waste or foreign bodies in our material.<br />

Our current customers have seen the<br />

difference in the finished product and<br />

there’s lots of interest from additional<br />

customers enquiring about buying our<br />

material.”<br />

In addition to keeping customers happy,<br />

then, TOMRA’s sorting machines are also a<br />

key which can unlock new business. One<br />

of many business leaders who will affirm<br />

this is Andy Kettle, Managing Director of<br />

GA Pet Food Partners, Europe’s leading<br />

manufacturer of private label premium<br />

dry pet food. Andy commented: “TOMRA’s<br />

technology has helped us break open new<br />

markets which previously would not have<br />

been available to us. For me, it has been<br />

one of the best investments made by the<br />

business in the last three to four years.”<br />

Technology & Marketing<br />

For more information<br />

www.tomra.com/petfood<br />

8<br />

Technology & Marketing

Pet Food<br />

Cutting<br />

Solutions<br />

As the #1 European and Global Leader in Food<br />

Cutting Technology, successful processors depend<br />

on Urschel's expertise to deliver optimal cutting<br />

solutions for all types of pet food ingredients.<br />

Urschel cutting equipment delivers a full<br />

spectrum of size reduction capabilities.<br />

Explore dicing, slicing, or pureeing to<br />

achieve your processing goals.<br />

NEW<br />

NEW<br />

#1 Best selling provider of<br />

industrial cutting machinery<br />

throughout the world.<br />

The Global Leader in Food Cutting Technology<br />

Set up a free test-cut of your product.<br />

www.urschel.com<br />

®Urschel, Urschel logo symbol, and The Global Leader in Food Cutting Technology<br />

are registered trademarks of Urschel Laboratories, Inc. U.S.A.

INGREDIENTS<br />

Tereos Launches Profeed<br />

ADVANCED®, a Complementary<br />

Feed to Support Dogs’ Immune<br />

Function<br />

Tereos is launching Profeed ADVANCED®,<br />

a complementary feed that is proven*<br />

to support the immune defence system<br />

in aging dogs. Developed jointly with<br />

Lallemand, a leading company in the<br />

development of yeast, bacteria, and<br />

their derivatives, Profeed ADVANCED®<br />

combines Tereos’ short-chain fructooligosaccharides<br />

(scFOS), already known<br />

as Profeed®, with new and unique selected<br />

yeast fractions to tackle the gut microbiota<br />

and immune changes in elderly dogs.<br />

Obtained from sugar beet sucrose,<br />

Profeed® short chain FOS encourages the<br />

growth of beneficial gut bacteria, while<br />

new Profeed ADVANCED® combines these<br />

proven prebiotic effects with the action of<br />

specifically selected yeast fractions, acting<br />

as postbiotics. This results in a synergistic<br />

effect for a unique complementary feed –<br />

for which a patent is still pending.<br />

Dr. Cindy Le Bourgot, Nutrition & Health<br />

Scientist at Tereos, explains: “Tereos’<br />

Profeed® range has been a favorite with<br />

petfood manufacturers for many years,<br />

and Profeed ADVANCED® is a real step<br />

forward in helping dogs stay healthier for<br />

longer. Science and innovation have come<br />

together to create a symbiotic product<br />

based on complementary modes of<br />

action, helping older dogs to stay healthier<br />

for longer.”<br />

In dogs, as in humans, the aging process<br />

leads to an alteration of the gut microbiota<br />

and a decrease in the efficacy of the<br />

immune system. Profeed ADVANCED®<br />

has been designed to support a balanced<br />

microbiota while sustaining the immune<br />

system through aging.<br />

Dr. Francesca Susca, Global Pet Product<br />

Manager at Lallemand Animal Nutrition<br />

(Tereos’ development partner), added:<br />

“Lallemand has worked for many years<br />

developing yeast and bacteria and their<br />

derivatives for humans and animals.<br />

We have selected specific yeast strains<br />

for Profeed ADVANCED® to develop<br />

a complementary feed with proven<br />

benefits in balancing the microbiota of<br />

senior dogs and helping to maintain their<br />

immunity. This is the first yeast derivatives<br />

product of this kind in the market.”<br />

Manufactured at Tereos’ facility in<br />

Chevrieres, France, the feed comes in the<br />

form of a neutral-tasting powder that can<br />

be added to any wet or dry petfood by<br />

manufacturers.<br />

Technology & Marketing<br />

For more information<br />

www.Tereos.com/en<br />

About Tereos<br />

Tereos is a cooperative union with<br />

11,200 cooperative members, with a<br />

recognised know-how in the processing<br />

of beet, sugarcane, cereals and potatoes.<br />

Through 43 industrial sites, presence in<br />

15 countries and the commitment of its<br />

15,800 employees, Tereos supports its<br />

customers close to their markets with<br />

a broad and complementary range of<br />

products. In 2022/23, the Group posted<br />

revenues of €6.6 billion.<br />

About Lallemand<br />

Lallemand Inc. is a privately held global<br />

company founded in Canada at the end of the<br />

19th century, specializing in the development,<br />

production, and marketing of microorganisms.<br />

The company serves the baking, winemaking,<br />

distilling, ethanol, brewing, animal nutrition,<br />

dietary supplements, food, fermentation,<br />

pharmaceutical and plant care industries.<br />

Lallemand currently has more than 5,000<br />

employees located in over 50 countries on five<br />

continents.<br />

For more information<br />

www.lallemand.com<br />

*Wambacq et al., 2022. Supplementation of<br />

a new combination of pre- and postbiotics<br />

to mitigate immunosenescence biomarkers<br />

and modify faecal microbiota of old dogs.<br />

Proceedings of the 26th European Society<br />

of Veterinary and Comparative Nutrition<br />

(ESVCN) Congress, Basel, Switzerland, 6-8<br />

September 2022.<br />

10<br />

Technology & Marketing

Low Glycaemic<br />

Properties of<br />

Isomaltulose<br />

Confirmed in Dogs<br />

Best in<br />

bioavailability!<br />

an important role to play, especially<br />

in regards to which carbohydrate is<br />

used in a dog’s food. Firstly, because<br />

overweight or obese pets are at risk<br />

of developing impaired glucose<br />

tolerance and insulin resistance.<br />

Secondly, low glycaemic diets have<br />

been shown to support weight loss<br />

and improve metabolic health in<br />

both humans and dogs iv . Therefore,<br />

finding suitable low glycaemic<br />

ingredients for dog food is key.<br />

CeF i<br />

®pro<br />

–<br />

Autolysed yeast!<br />

A new series of in-vitro and in-vivo studies<br />

initiated by BENEO and conducted by<br />

Corbee et al i , have evaluated the digestion<br />

of isomaltulose, as well as its glycaemic<br />

and insulinaemic effects in dogs,<br />

compared to other relevant carbohydrate<br />

sources. The study results demonstrate<br />

that isomaltulose is a suitable low<br />

glycaemic ingredient for use in dog food,<br />

triggering a lower blood glucose rise after<br />

consumption. This property makes it a<br />

particularly interesting solution with the<br />

potential to support metabolic health<br />

and weight management.<br />

Numbers of overweight and obese<br />

dogs have steadily increased over the<br />

last few decades and exceed 50% in<br />

Western countries ii . Excessive weight<br />

is linked to metabolic and skeletal<br />

associated disorders and impacts the<br />

quality of life of both dog and owner.<br />

This is reflected in pet owners’ interest<br />

in tackling such issues: More than 8 in<br />

10 pet owners worldwide agree that onpack<br />

communication about helping to<br />

control their pet’s weight naturally (87%),<br />

or having a lower impact on blood sugar<br />

levels (85%), very much or somewhat<br />

affects their purchase intention of a pet<br />

food product iii . Here, nutrient choice has<br />

In total, three studies were carried out by<br />

the teams from universities in Utrecht and<br />

Wageningen. The first, an in-vitro study<br />

of small intestinal tissue samples from<br />

three dogs, evaluated the small intestinal<br />

hydrolysis of isomaltulose compared<br />

to sucrose, maltose, maltodextrin,<br />

lactose and α-trehalose. The aim was to<br />

confirm if dogs have the ability to digest<br />

isomaltulose, as well as compare it with<br />

other carbohydrate sources. The findings<br />

showed that it can be digested by canine<br />

intestinal enzymes, with a lower enzyme<br />

activity compared to high glycaemic<br />

carbohydrates, indicating a slower rate of<br />

hydrolysis.<br />

The second and third studies compared<br />

the effects of isomaltulose, sucrose and<br />

maltodextrin in an in-vivo set-up. One<br />

of the studies assessed the glycaemic<br />

effects of the three carbohydrates<br />

in nine dogs and using a 3x3 Latinsquare<br />

design v . After an overnight fast,<br />

the blood glycaemia and insulinaemia<br />

were measured 0-180 minutes after<br />

the administration of a single dose<br />

of either isomaltulose, sucrose or<br />

maltodextrin. The results showed that<br />

isomaltulose significantly lowered<br />

blood glucose and insulin responses in<br />

the dogs, compared to maltodextrin or<br />

sucrose.<br />

| free amino acids &<br />

nucleotides<br />

| promotes intestinal<br />

integrity<br />

| stimulates metabolism<br />

| enhances palatability<br />

Visit our website:<br />

leibergmbh.de<br />

Leiber GmbH | Franz-Leiber-Straße 1 | 49565 Bramsche<br />

Germany | info@leibergmbh.de

INGREDIENTS<br />

The goal of the final study was to assess<br />

the glycaemic properties of isomaltulose<br />

in dogs, after continuous intake. This was<br />

based on the assumption that the abilities<br />

to digest isomaltulose might evolve<br />

through adaptation, so that its impact on<br />

blood glucose levels would get closer to<br />

the other carbohydrates. In this study, 18<br />

dogs received a 50:50 mix of isomaltulose<br />

and sucrose (1g per kg bodyweight) daily<br />

for two weeks. They were then split into<br />

three equal groups which each received<br />

a single dose of either isomaltulose,<br />

sucrose or maltodextrin after an<br />

overnight fast. Following this, the dogs’<br />

blood glucose and insulin responses were<br />

measured. Even after continuous intake<br />

over two weeks, the low glycaemic and<br />

insulinaemic properties of isomaltulose<br />

were confirmed.<br />

About BENEO<br />

BENEO-Animal Nutrition offers a broad<br />

range of natural ingredients with<br />

nutritional benefits. The product range<br />

is comprised of vegetable proteins,<br />

digestible carbohydrates, prebiotic<br />

chicory root fibers and specialty rice<br />

ingredients. BENEO-Animal Nutrition<br />

extends BENEO´s unique expertise in<br />

human food to the world of pet food,<br />

livestock feed and aqua feed.<br />

Commenting on the findings, Dr Maygane<br />

Ronsmans, Product Manager Animal<br />

Nutrition at BENEO says: “This research<br />

is of great importance as it offers the<br />

first comprehensive characterisation<br />

of isomaltulose with respect to its<br />

digestibility and metabolic effects in<br />

dogs. The low glycaemic properties of<br />

isomaltulose already shown in other<br />

species, including humans, pigs and<br />

rodents, have now been confirmed in<br />

dogs. The combined results of this study<br />

suggest that isomaltulose would be<br />

a suitable energy source in dog food,<br />

which contributes to a more stable blood<br />

glucose response, and may improve the<br />

dog’s metabolic profile and overall health.”<br />

Isomaltulose is a disaccharide which<br />

occurs naturally in honey. It is composed<br />

of glucose and fructose, characterised by<br />

a stronger glycosidic bond than that of<br />

usual sugar. Isomaltulose is a direct source<br />

of energy that generates a more balanced<br />

blood glucose response, distinguishing<br />

it from high glycaemic energy sources,<br />

such as heat treated cereals and<br />

conventional sugars (e.g. dextrose).<br />

BENEO derives isomaltulose from sugar<br />

beet at its production plant for functional<br />

carbohydrates in Offstein, Germany.<br />

References<br />

Technology & Marketing<br />

Animal Physiology and Animal Nutrition, 1–<br />

9. https://doi.org/10.1111/jpn.13860<br />

ii<br />

Read, C. (2019). The growth of pet obesity.<br />

The Veterinary record 185, 1–3. https://doi.<br />

org/10.1136/vr.l6498<br />

German, A.J., Woods, G.R.T., Holden, S.L.,<br />

Brennan, L. & Burke, C. (2018). Dangerous<br />

trends in pet obesity. Veterinary Record, 182:<br />

25. https://doi.org/10.1136/vr.k2<br />

iii<br />

BENEO Consumer Research on Attitudes<br />

towards Pet Food in US, Brazil, UK, Germany<br />

& China 2021<br />

iv<br />

Mitsuhashi Y, Nagaoka D, Bigley KE, Umeda<br />

T, Otsuji K, Bauer JE (2012). Metabolic and<br />

Hormonal Alterations with Diacylglycerol<br />

and Low Glycemic Index Starch during<br />

Canine Weight Loss. ISRN Veterinary Science<br />

2012: 750593. doi: 10.5402/2012/750593.<br />

https://www.ncbi.nlm.nih.gov/pmc/articles/<br />

PMC3671726/<br />

v<br />

A Latin-square design is a method of placing<br />

treatments so that they appear in a balanced<br />

fashion within a square block or field.<br />

Treatments are assigned at random within<br />

rows and columns, with each treatment once<br />

per row and once per column.<br />

BENEO, a division of the Südzucker<br />

Group, employs more than 1000<br />

people and has production units in<br />

Belgium, Chile, Germany, Italy, and the<br />

Netherlands.<br />

i<br />

Corbee, R. J., Mes, J. J., de Jong, G. A. H., van den<br />

Dool, R. T. M., Neumer, F., Theis, S., & Bosch, G.<br />

(<strong>2023</strong>). Brush border enzyme hydrolysis and<br />

glycaemic effects of isomaltulose compared<br />

to other saccharides in dogs. Journal of<br />

For more information<br />

www.beneo.com<br />

12<br />

Technology & Marketing

WE MAKE PET FOOD<br />

TASTE GREAT. TM<br />

AFB partners with pet food companies<br />

to provide palatant solutions that meet<br />

performance, attribute, and economic<br />

objectives.<br />

Contact your AFB account manager to<br />

discuss your unique palatant needs.<br />

AFBInternational.com<br />

©2022 AFB International

INGREDIENTS<br />

High-quality, Functional, and<br />

Sustainable: the Current Trends in<br />

Natural Dog Nutrition<br />

Just as human diets are different, so are those of our pets: True to the motto "what's good for me can't be bad for my dog",<br />

owners (unconsciously) adapt their pet's diet more and more to their own. Preferably fresh and natural ingredients find<br />

their way into the bowl – with a demand for quality and positive health effects. The nutritional spectrum ranges from<br />

regional, vegan, and protein-rich food components, to selected organic products and individual oil blends.<br />

1. High-quality and natural pet<br />

food components<br />

The pet food market is becoming<br />

increasingly "green": more and more pet<br />

parents are paying attention to natural,<br />

sustainable nutrition and care about<br />

the health and well-being of their furry<br />

friends. This also reflects the owners’<br />

increased awareness of environmental<br />

protection and animal welfare.<br />

They increasingly value high-quality<br />

ingredients for pet food made from<br />

natural raw materials and unprocessed<br />

ingredients. "Clean Feeding" serves<br />

this trend: the concept envisions dog<br />

foods that are as natural as possible and<br />

usually consist of half animal protein,<br />

30 to 40 percent plant-based products,<br />

10 to 20 percent carbohydrates, and<br />

a small number of high-quality oils.<br />

Additives such as artificial colors, flavors,<br />

and preservatives as well as genetically<br />

modified ingredients (GMOs) are largely<br />

avoided.<br />

Pet owners are paying more attention to<br />

the origin of food and are turning to organic<br />

products, meat from species-appropriate<br />

farming, and fish from sustainable wild<br />

catches. Many manufacturers are already<br />

responding to the demand for organic pet<br />

food: with organic-certified ingredients<br />

and products, they assure their customers<br />

of an organic standard that excludes the<br />

use of chemical fertilizers, pesticides, or<br />

antibiotics. The menu also more often<br />

includes local fruits and vegetables<br />

from certified organic cultivation. Local<br />

products usually have shorter transport<br />

routes and can be consumed or processed<br />

more quickly. This has a positive impact on<br />

product quality and freshness, but also on<br />

the environment thanks to the reduced<br />

carbon footprint. Buying these products<br />

also supports local farmers and promotes<br />

the local economy.<br />

In addition to the origin of raw materials,<br />

pet owners are also interested in their<br />

sustainable processing: They demand<br />

transparency and prefer environmentally<br />

friendly manufacturing processes that<br />

gently preserve the valuable nutrients of<br />

the raw goods. Transparent label design<br />

helps them understand the composition<br />

of products better. In this way, pet<br />

owners ensure that the food chosen<br />

meets their dog's nutritional needs and<br />

can also identify and avoid undesirable<br />

ingredients in case of allergies and<br />

intolerances.<br />

2. Healthy and functional<br />

ingredients<br />

The demands on animal nutrition have<br />

become more complex in recent years<br />

– besides qualitative and sustainable<br />

criteria, it should be functional and<br />

healthy. According to a Mintel study,<br />

there is a clear trend in this direction: 63<br />

percent of German pet owners would<br />

like to know more about their pet's brain<br />

health and 57 percent are interested in<br />

food components that promote their<br />

pet's intestinal health. Functional food<br />

contains selected ingredients that, on the<br />

one hand, meet the pet's basic nutritional<br />

needs and, on the other, support its<br />

general well-being.<br />

Recently, there has been increasing<br />

demand for grain-free pet food to avoid<br />

potential allergies and intolerances and to<br />

improve intestinal health. Generally, grains<br />

are a good plant source of carbohydrates<br />

and fiber that most dogs can digest well.<br />

However, some have sensitive reactions to<br />

certain grains such as wheat or soy.<br />

This approach goes hand in hand with<br />

the trend to feed purely plant-based<br />

components. Following the example of<br />

vegetarian and vegan diets among us<br />

14<br />

Technology & Marketing

INGREDIENTS<br />

humans, owners sometimes want to feed<br />

their dogs a vegan diet as well – but they<br />

do not want to sacrifice nutritional value,<br />

such as protein and amino acid content.<br />

While meat has long been considered the<br />

main source of protein in animal nutrition,<br />

nowadays more and more plant-based<br />

protein sources are being integrated into<br />

the diet.<br />

Plant-based food components<br />

Vegetable oils, such as linseed, hemp, or<br />

olive oil, can provide valuable nutrients<br />

in dog nutrition: As a partner for natural<br />

raw materials, Henry Lamotte Oils offers<br />

a broad portfolio of essential ingredients<br />

for animal nutrition.<br />

In the company's own Oil Mill Lipos, the<br />

gentle pressing of oilseeds produces highquality<br />

oils and protein-containing press<br />

cakes that are ideal as food ingredients<br />

for dog nutrition. Fine grinding turns<br />

them into LipoMill Flours, which, with a<br />

residual oil content of five to ten percent,<br />

are rich in protein and dietary fiber. They<br />

enrich pet food with valuable omega fatty<br />

acids, amino acids, minerals, and trace<br />

elements.<br />

Vegetable extrudates that resemble<br />

meat in appearance are also becoming<br />

more popular. They are produced, for<br />

example, from organic sunflower seeds<br />

using an extrusion process. The press<br />

cake contains all nine essential amino<br />

acids that neither the human nor the<br />

animal body can produce on its own.<br />

With a high protein content of over 50<br />

percent, the extrudate is an ideal vegan<br />

alternative to the conventional protein<br />

supplier meat.<br />

Algae products are also being used<br />

more frequently in animal nutrition as<br />

a plant-based alternative to fish oils.<br />

Microalgae such as chlorella or spirulina<br />

contain the valuable omega-3 fatty<br />

acids eicosapentaenoic acid (EPA) and<br />

docosahexaenoic acid (DHA). These can<br />

contribute to maintaining the health of<br />

the brain, joints, skin, and fur. In animal<br />

nutrition, algae can be added in the form<br />

of oils or flours.<br />

Jan-Christoph Morisse – Head of Sales Animal<br />

Nutrition & Care / Chemical Technical Industry at<br />

Henry Lamotte Oils. Henry Lamotte Oils is a leading<br />

quality supplier of natural oils and related products<br />

such as vegetable butters, waxes, protein flours and<br />

oleoresins. The company's Oil Mill Lipos primarily<br />

processes organic seeds into oils and press cakes.<br />

Find your solution<br />

Barentz Animal Nutrition is a global distributor of<br />

technical and nutritional ingredients for the pet food<br />

industry. We have several solutions for clean label,<br />

hypoallergenic, digestive support, sustainable, vegetarian<br />

and organic concepts. Always a better solution.<br />

Plant-based<br />

proteins<br />

Antioxidants Colours Hydrocolloids Insect Protein Yeasts Seaweed<br />

barentz.com Always a better solution.<br />

Barentz<br />

Saturnusstraat 15<br />

2132 HB Hoofddorp, The Netherlands<br />

Issue 3 <strong>2023</strong><br />

T + 31 (0) 23 5673456<br />

E petfoodinfo@barentz.com<br />

I www.barentz.com/animal-nutrition<br />

15

INGREDIENTS<br />

Examples of flour packages<br />

BARF feeding<br />

In contrast to the feeding of plantbased<br />

food components, there are<br />

many supporters of a meat-based diet<br />

with animal proteins. They associate<br />

biologically appropriate raw food (BARF)<br />

with a near-natural diet, which they<br />

believe meets the natural needs of the<br />

dog best. In this form of nutrition, pets are<br />

fed meat, bones, and innards. Fruits and<br />

vegetables are added in small quantities<br />

as components. Fish oils, for example, can<br />

be used as a supplement in the BARF diet<br />

because of their high content of omega-3<br />

fatty acids. The EPA and DHA they contain<br />

Algae Pouder<br />

have a positive effect<br />

on the cardiovascular<br />

system and are involved<br />

in many metabolic<br />

processes.<br />

In a study, researchers<br />

from the University of<br />

Winchester in the United<br />

Kingdom and Australia’s<br />

Griffith University<br />

examined three different<br />

diets for dogs and the<br />

effect on their health. A<br />

total of 2536 dogs took<br />

part in the study: 54<br />

percent of them were<br />

fed a mixed diet with<br />

components of meat,<br />

grains and vegetables,<br />

33 percent were fed<br />

exclusively raw meat<br />

(BARF) and 13 percent<br />

were fed a purely plantbased<br />

diet. Considering<br />

various indicators,<br />

specific impairments were examined,<br />

such as gastrointestinal diseases, diseases<br />

of the musculoskeletal system, and of the<br />

skin and ears. According to the study, on<br />

average, the experimental group of dogs<br />

fed a vegan diet was less susceptible to<br />

disease. In contrast, just under half of<br />

the group fed the conventional mixed<br />

diet suffered from health problems. The<br />

dogs fed raw meat did slightly better in<br />

the study. In direct comparison, however,<br />

they were significantly younger than<br />

the vegan-fed group. It is not possible<br />

to clearly determine which diet is the<br />

healthiest: A raw meat diet tends to<br />

carry an increased risk of pathogens and<br />

malnutrition, whereas the vegan diet was<br />

the least risky choice, according to the<br />

study.<br />

3. Customized<br />

product solutions<br />

Personalized products<br />

tailored to the individual<br />

needs and preferences<br />

of one's own pet are<br />

a clear trend resulting<br />

from increasing pet<br />

humanization. Pet<br />

owners consider their<br />

pets as family members<br />

and companions for life,<br />

whose well-being they<br />

want to ensure in all<br />

respects. For this reason,<br />

owners are intensively concerned with a<br />

healthy diet and sustainable care for their<br />

furry friends. Premiumization goes hand in<br />

hand with this development: pet owners<br />

are happy to spend more money on their<br />

dogs if they expect the products to be<br />

of high quality or if they consider them<br />

to be beneficial to their health. Beyond<br />

nutrition and care, premiumization is also<br />

evident in pet accessories and innovative<br />

services. Personalized products create<br />

individuality, strengthen the bond, and<br />

express increased attention.<br />

Individual and environmentally<br />

friendly – Private Label<br />

packaging<br />

On the manufacturers' side, this trend<br />

is also having an impact on product<br />

development. The desire for individual<br />

pet food and oil mixtures is growing to<br />

adapt the diet even better to the dog's<br />

personal needs. In the field of Private<br />

Label bottling, Henry Lamotte Oils uses<br />

its years of expertise to realize individual<br />

product ideas and manufacture<br />

according to desired specifications.<br />

Customized products need well-chosen<br />

packaging: In addition to their functional<br />

and aesthetic criteria, these also meet<br />

requirements for product protection<br />

and are increasingly made of more<br />

environmentally friendly materials<br />

that are recyclable or biodegradable.<br />

Environmentally friendly packaging<br />

solutions help reduce the carbon<br />

footprint and harmful emissions.<br />

With several options available,<br />

environmentally conscious pet owners<br />

often go for the sustainable option.<br />

Regarding oils and flours, different<br />

variants are available for feed packaging.<br />

Glass bottles for oils, for example, offer the<br />

advantage that they are easily recyclable<br />

and do not interact with other substances.<br />

However, melting them down after their<br />

single use requires high temperatures.<br />

Metal cans are unbreakable, light-proof,<br />

and customizable. They have a similar<br />

recycled content to glass bottles, but are<br />

less material-intensive, making them a<br />

possible alternative to glass.<br />

Stand-up pouches made of (kraft) paper<br />

are ideal for feed components such as<br />

flours or extrudates. In contrast to plastic<br />

tins, they are only half as heavy when<br />

empty and reduce costs and emissions<br />

thanks to their minimal transport volume.<br />

Technology & Marketing<br />

16<br />

Technology & Marketing

INGREDIENTS<br />

Natural bioactive ingredient<br />

to soothe pets<br />

Sunflower extracts<br />

(1) Mintel (2021), Vegan dog food and<br />

functional pet food for the well-being of<br />

the animal on the rise, URL: https://www.<br />

mintel.com/de/press-centre/veganeshundefutter-und-funktionelles-tierfutterfur-das-wohlbefinden-des-haustieres-imkommen/<br />

(04.08.<strong>2023</strong>)<br />

(2) PLOS ONE (2022), Vegan versus meatbased<br />

dog food, URL: https://journals.plos.<br />

org/plosone/article?id=10.1371/journal.<br />

pone.0265662 (04.08.<strong>2023</strong>)<br />

Examples of oil packs<br />

For more information<br />

www.lamotte-oils.de/en<br />

Issue 3 <strong>2023</strong><br />

17

INGREDIENTS<br />

Protection of Pet Food with<br />

Natural and Cost-effective<br />

Antioxidants Solutions<br />

Innovative systems to protect new sources of animal proteins<br />

extract is showing excellent performances<br />

in various types of animal proteins and<br />

fats. Mixed tocopherols, vitamin E itself<br />

and Rosemary Extract (botanical extract)<br />

are commonly used in the industry. Our<br />

large Toco-PET range can be used to<br />

protect the many types of meals and fat<br />

used by the industry.<br />

Change is around the corner<br />

A concern for naturalness in human foods<br />

has extended to a greater awareness<br />

about additives in pet food. This has<br />

been accompanied by a slow but steady<br />

increase in the re-evaluation of the safety<br />

of synthetic antioxidants in pet food.<br />

This re-evaluation has extended to the<br />

antioxidants butylated hydroxyanisole<br />

(BHA) and butylated hydroxytoluene<br />

(BHT). Most current concerns are<br />

expressed over BHA and, in particular, its<br />

re-authorization for use in cat food.<br />

Alternatives<br />

The transition from synthetics (BHA and<br />

BHT) to natural additives might reveal<br />

that naturalness comes with a challenge<br />

– in terms of both cost and the stability<br />

of the pet food. Therefore, more attention<br />

should be paid to the synergy between<br />

naturals and ‘more acceptable’ synthetics<br />

used in food systems with proven longstanding<br />

safety, such as infant nutrition.<br />

Ascorbates, gallates and chelates work<br />

well with natural antioxidants and are costeffective.<br />

The drivers of these compounds<br />

work together and are suitable for use<br />

in the pet food process. Pet-Safe (which<br />

does not contain BHA/BHT) offers a<br />

great alternative to standard synthetic<br />

antioxidants with a very competitive cost<br />

in use. This provides a very interesting<br />

opportunity for those looking for a<br />

transition between the synthetic and fully<br />

natural solutions.<br />

Synergies of natural options<br />

During the last 20 years, Vitablend<br />

technical team has worked and developed<br />

synergistic solutions using natural and<br />

traditional active compounds to provide<br />

meals, fats, oils, petfood producers with<br />

the solution offering the best cost in use.<br />

This approach helps us developing natural<br />

system offering similar performances of<br />

traditional synthetic antioxidants. The<br />

combination of tocopherols and rosemary<br />

What’s next…. new sources of<br />

proteins<br />

To sustain the increasing demand, the<br />

industry is now looking at new sources<br />

of animal proteins. Vitablend has done<br />

extensive research to find the best<br />

alternatives to protect insect meals and<br />

fat. This type of matrix can contain up to<br />

45% fat which contains polyunsaturated<br />

fatty acids very sensitive to oxidation.<br />

In our recent studies we have tested<br />

various antioxidants systems. Antioxidant<br />

capacity was measured by the induction<br />

point (hrs) to oxidation under accelerated<br />

conditions. The study showed that our<br />

Toco-PET TR 10 L (Tocopherols and<br />

Rosemary Extract) provides a similar level<br />

of protection as a traditional BHA/BHT<br />

synthetic system, enhancing the shelf life<br />

up to 50%. Our Toco-PET TR 10 L is one<br />

example of a very versatile system which<br />

can be used to protect multiple type of<br />

meals and oils.<br />

Technology & Marketing<br />

Vitablend is a manufacturer of<br />

antioxidants and nutritional systems. It<br />

is part of the Barentz Group, and has its<br />

HQ in The Netherlands, factories in The<br />

Netherlands, USA and Singapore.<br />

For more information<br />

www.barentz.com<br />

petfoodinfo@barentz.com<br />

18<br />

Technology & Marketing

Insects in Pet Food: Do Insect<br />

Larvae Outcompete Classic<br />

Protein Sources?<br />

INGREDIENTS<br />

The demand for insect based pet food is growing in global<br />

markets. Forecasts predict significant growth rates for pet food<br />

with ingredients derived from insects in the coming years. Pet<br />

owners desire the best possible nutrition for their four-legged<br />

companions. However, pet foods with a high meat content<br />

regularly have an unfavorable environmental footprint. Customers<br />

are becoming increasingly aware of this trait. Insect based feeds<br />

may help to significantly improve the ecological footprint of pet<br />

food. Wholesome insect granules contain valuable nutrients and<br />

thus equally offer benefits for animal health and the environment.<br />

Insect based pet food market suggests enormous<br />

potential<br />

With rising protein demand for food and feed, increasing<br />

uncertainty in global commodity markets, and not least as a result<br />

of dramatic climatic changes, demands for alternative, regionally<br />

produced nutrients are growing.<br />

Insect based feeds are projected to grow at an average annual rate<br />

of 9.3 percent in the market through 2030 (Future Market Insights,<br />

2021). These forecasts are also in line with consumer attitudes:<br />

In recent studies, up to 50 percent of the pet owners surveyed<br />

already stated that they could very well imagine insect based<br />

feeds as an alternative for their dogs and cats.<br />

HIGHLY EFFICIENT FEED CONVERSION<br />

INSECTS POULTRY PORK<br />

Land use (m 2 /kg)<br />

Water use (l/kg)<br />

Feed conversion<br />

(DM feed/kg fresh mass)<br />

Fig. 1: Insects are the most efficient users of precious raw materials<br />

In this light, many pet owners are increasingly keen to ensure<br />

that what they fill their four-legged friends' bowls with originates<br />

from sustainable sources. As an alternative to pork, poultry or fish,<br />

insects in pet food offer numerous advantages:<br />

The range of insect based pet food already is correspondingly<br />

large: Products range from snacks and chews to classic dry and<br />

wet food varieties as well as special hypoallergenic feeds that can<br />

be purchased exclusively from veterinary practices.<br />

Technology & Marketing<br />

Technology & Marketing<br />

In particular, products based on Black Soldier Fly Larvae (BSFL) are<br />

becoming increasingly popular. Compared to mealworms, they<br />

can not only be produced more cost-effectively and sustainably.<br />

Their nutritional spectrum, with higher levels of calcium and<br />

phosphorus, for example, also proves advantageous.<br />

Technology & Marketing<br />

Technology & Marketing<br />

Contributing to sustainability in pet food<br />

The production of food for around 25 million dogs and cats in<br />

German households alone not only leaves an unfavorable footprint<br />

on the eco-balance of domestic agriculture. It also contributes to<br />

global environmental impacts: Much of the soy used to provide<br />

protein for meat-supplying livestock originates from regions<br />

where valuable natural areas are cleared for its cultivation. Social<br />

tensions in the countries of origin and climatic changes worldwide<br />

clearly show that there are limits to this approach.<br />

Insects can save natural raw materials, especially large<br />

amounts of water.<br />

Insects can recycle residual materials from agriculture<br />

and the food industry into high-quality ingredients.<br />

Regionally reared insects can reduce transport distances<br />

and greenhouse gas emissions.<br />

Thanks to vertical farming, significantly less space is<br />

required for insect fattening than in conventional animal<br />

husbandry.<br />

Insect larvae - a high-quality and healthy source<br />

of nutrients.<br />

To dogs and cats the following applies as well: selected ingredients<br />

in food support important metabolic functions and promote<br />

vitality.<br />

Issue 3 <strong>2023</strong><br />

21

INGREDIENTS<br />

NUTRIENT SOURCE + PURINES<br />

g/100g<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

0Soy Extract Fish meal Meat PAP BSFL PAP<br />

Protein Fat Ash Fiber Purines (x100)<br />

Fig. 2: BSFL’s ratio of key ingredients is most finely balanced<br />

The exoskeletons of insects, the so-called exuviae, largely consist<br />

of the polysaccharide chitin, a crude fiber component suitable for<br />

animal feed. It has also been shown that chitin and its derivative<br />

chitosan may stimulate the immune system and thus strengthen<br />

the animals' internal defenses against external influences.<br />

Wholesome insect granules as a source for pet<br />

food.<br />

The processing procedure for full-fat insect granules is<br />

coordinated in such a way that all valuable ingredients of the<br />

larvae are retained. Compared to partially defatted meals, full-fat<br />

granules utilize the entire potential of the BSFL. This high-quality<br />

raw material thus contains all the natural energy of the insect fat,<br />

and the antimicrobial and antioxidant effects of the bioactive<br />

ingredients can also be used completely.<br />

Black Soldier Fly Larvae (BSFL) naturally contain high-quality<br />

and easily digestible nutrients: protein and fat, minerals such<br />

as copper, iron, magnesium, manganese, selenium and zinc, as<br />

well as various (B-) vitamins are present in a balanced ratio. Insect<br />

protein contains all the essential amino acids, and insect fat is<br />

highly energetic and has a valuable fatty acid content - about 50<br />

percent lauric acid alone.<br />

For most pets, protein from insects is also an as yet unknown<br />

protein source and is therefore considered a promising protein<br />

alternative in case of feed allergies and intolerances.<br />

Color<br />

Odor<br />

Post-darkening in process<br />

Health<br />

Powder<br />

Granules<br />

Post-clumping<br />

Regional<br />

Friendly<br />

Sustainable<br />

Humidity<br />

Beige<br />

Sweet biscuits-coconut-chocolate<br />

No<br />

Laurine+amino acid+fibers<br />

Flowable<br />

Ingredo ProBug Granulate<br />

No<br />

Yes<br />

Support farmers<br />

No by-products<br />

1-14%<br />

Fig. 4: Wholesome insect granules have very valuable properties<br />

AMINO ACID DISTRIBUTION<br />

g/100g<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

Technical aspects also speak in favor of the use of wholesome<br />

insect meal in animal feed: for example, it is much easier to utilize<br />

during processing. The material has a much lower tendency to<br />

batch and its flowability is remarkable. Feed components based<br />

on full-fat meal prove to be color- and odor-solid and enable a<br />

stable and homogeneous end product.<br />

0<br />

Arginine<br />

Cysteine<br />

Glycine<br />

Histidine<br />

Isoleucine<br />

Leucine<br />

Lysine<br />

Methionine<br />

Phenylalanine<br />

Serine<br />

Threonine<br />

Tryptophan<br />

Valine<br />

Technology & Marketing<br />

Soy Extract Fish meal Meat PAP BSFL PAP<br />

Fig. 3: BSFL protein is characterized by an optimal amino acid profile<br />

Bioactive ingredients stimulate internal defenses<br />

Insect larvae are exposed to numerous germs in their natural<br />

habitat and they need effective mechanisms to defend<br />

themselves against them. With the help of antimicrobial peptides<br />

(AMP) and a high content of lauric acid, BSFL keep bacteria,<br />

viruses and fungi at bay.<br />

The AMP contained in BSFL, as well as the high concentration of<br />

medium-chain lauric acid (MCFA) in the fat, also offer benefits<br />

to dogs and cats: Ingested in the feed, they can support animal<br />

health with their antimicrobial as well as antioxidant effects.<br />

• Siddiqui S. Brunner T. et al.: “Insect-based dog and cat food: A short investigative review on market, claims<br />

and consumer perception.” Journal of Asia-Pacific Entomology, <strong>2023</strong>; Vol.26, Issue 1.<br />

• Veldkamp T., Dong L. et al.: "Bioactive properties of insect products for monogastric animals – a review".<br />

Journal of Insects as Food and Feed, 2022; 8(9): 1027-1040. SPECIAL ISSUE: Insects on the monogastric<br />

menu.<br />

• Valdés F., Villanueva V. et al.: “Insects as Feed for Companion and Exotic Pets: A Current Trend.” Animals,<br />

2022; 12.<br />

• Freel T., McComb A. et al.: “Digestibility and safety of dry black soldier fly larvae meal and black soldier fly<br />

larvae oil in dogs.” Journal of Animal Science, 2021; Vol.99, No.3: 1-8.<br />

Join the Pet food Symposium in October!<br />

For more information<br />

https://tiny.one/farminsect<br />

22<br />

Technology & Marketing

INGREDIENTS<br />

Nutrition Brand Evolution<br />

Symrise Pet Food has announced to transform its nutrition ingredients brand into<br />

Nuvin. This includes plans to expand growth and advance sustainability for the<br />

complete offering of egg, chicken, hydrolyzed proteins, and health solutions. With<br />

this step, the company intends to strategically strengthen its pet food offering for<br />

its customers.<br />

With this brand evolution, Symrise Pet<br />

Food moves to achieve key aspects of its<br />

longer-term strategy. At the same time, it<br />

continues to supply its customers with the<br />

fundamental ingredients and collaborative<br />

services essential to premium formulations.<br />

Further pursuits in natural<br />

nourishment<br />

The new brand inherits a thriving portfolio<br />

in natural pet nutrition: value-added egg<br />

in the form of Ovalin nutritional products<br />

and OvaBind binding and emulsification<br />

ingredients for functional applications.<br />

Pepti'One hydrolysates come from a range<br />

of select, single-source animal proteins.<br />

Premium-quality chicken protein, broth,<br />

and fat for dry and wet formulations also<br />

add to the portfolio as well as health<br />

solutions.<br />

"Clearly, the initial brand served us well<br />

in establishing a footing in the global<br />

marketplace. It also helped us setting<br />

the tone for our authoritative position<br />

in quality, safety, and sustainability,"<br />

explains John Tiedeman, General Manager,<br />

Nutrition Business Line at Symrise Pet Food.<br />

"Now, Nuvin picks up where Nutrios<br />

leaves off. This reflects our determination<br />

to elevate the existing brand equity with<br />

greater innovation as we move into an<br />

intensified strategic phase of growth and<br />

vitality."<br />

and functional solutions to visibly improve<br />

pet health and wellness.<br />

Existing Symrise facilities, systems, and<br />

personnel will continue to provide these<br />

products and services as the Nuvin brand<br />

transformation proceeds.<br />

Technology & Marketing<br />

For more information<br />

www.symrise.com<br />

These industry-leading product lines will<br />

retain their existing individual branding.<br />

Nuvin advances its ingredients and<br />

associated capabilities in service to<br />

customers, consumers, and their pets.<br />

Building on collaborative<br />

expertise<br />

Nuvin fields a distinguished team of<br />

researchers, developers, and marketing<br />

specialists with proven experience in<br />

intensive product development, based on<br />

all-natural, foundational ingredients. For<br />

customers that want to premiumize their<br />

offerings, these experts create nutritious<br />

Improving Quality of Life<br />

for our most trusted companions<br />

• Bioactive Collagen Peptides (BCP ® ) proven<br />

to stimulate joint cartilage metabolism in pets<br />

• A pure non-allergenic collagen protein<br />

for clean label products<br />

Issue 3 <strong>2023</strong><br />

GELITA AG · Uferstr. 7 · 69412 Eberbach · Germany · www.gelita.com<br />

23

PROCESSING<br />

Efficient Process Technology for<br />

Dogs and Cats<br />

The demand for veterinary products is increasing worldwide – and with it the need for particularly efficient, hygienic<br />

manufacturing processes. As the example of chewable tablets for dogs and cats shows, Ploughshare® Mixers can meet the<br />

specific requirements particularly well in several respects.<br />

Pet owners worldwide spend over 135<br />

billion euros on their pets. In the USA<br />

alone, the figure is almost 60 billion, in<br />

Western Europe around 30 billion – per<br />

year and rising. Veterinary medicines<br />

account for a significant proportion of<br />

this expenditure.<br />

Specialized manufacturers are<br />

responding to this growing demand<br />

by expanding their capacities, not only<br />

with additional equipment, but above<br />

all with increasingly efficient production<br />

processes. How this could look in practice<br />

is shown by a particularly widespread<br />

form of administration: Chewable tablets<br />

for dogs and cats.<br />

Raw materials and process<br />

From a technical process point of view,<br />

such chewable tablets mainly consist<br />

of dry raw materials: In the basic recipe,<br />

Active Pharmaceutical Ingredients (APIs)<br />

or other additives, such as vitamins or<br />

flavors, are added to a basic product (e.g.<br />

corn starch or protein powder). The first<br />

intermediate product is thus a powdery<br />

dry mixture.<br />

After this premixing, liquid components,<br />

e.g. liquid polymer (PEG or macrogol) or<br />

oils (e.g. soya oil, fish oil) are added and<br />

incorporated in a second step. At room<br />

temperature, however, these liquids can<br />

harden or crystallise in contact with the<br />

mixer or the mixed material before they<br />

are completely distributed. Therefore,<br />

both the mixer and the dry mix must<br />

be tempered beforehand. Usually it<br />

is heated to around +50 – 60 °C to<br />

optimise distribution of the added liquid<br />

components in the dry mixture.<br />

After another mixing process, a highly<br />

pasty, marzipan-like dough is formed.<br />

After emptying the mixer, the mixture is<br />

transferred to a moulding machine as a<br />

lump or dough strand. Finally, the formed<br />

tablets are baked through and packaged.<br />

Ploughshare®<br />

Mixer FKM as<br />

a particularly<br />

efficient<br />

solution<br />

Both mixing steps<br />

take place one after<br />

the other in the<br />

same machine and<br />

in batch operation.<br />

Ploughshare®<br />

Mixers FKM from<br />

Lödige Process<br />

Technology with<br />

600 to 3000 l<br />

nominal volume have already proven<br />

themselves many times over. They operate<br />

based on the mechanically generated<br />

fluid bed that ensures a very good mixing<br />

performance and was introduced to<br />

industrial mixing technology by Lödige:<br />

the specially developed shovels rotate<br />

close to the wall inside a horizontal<br />

drum, creating the fluid bed. The process<br />

enables a high degree of homogeneity<br />