Form 155.16-N3 (899), IsoFlow Absorption Chillers with Buffalo ...

Form 155.16-N3 (899), IsoFlow Absorption Chillers with Buffalo ...

Form 155.16-N3 (899), IsoFlow Absorption Chillers with Buffalo ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

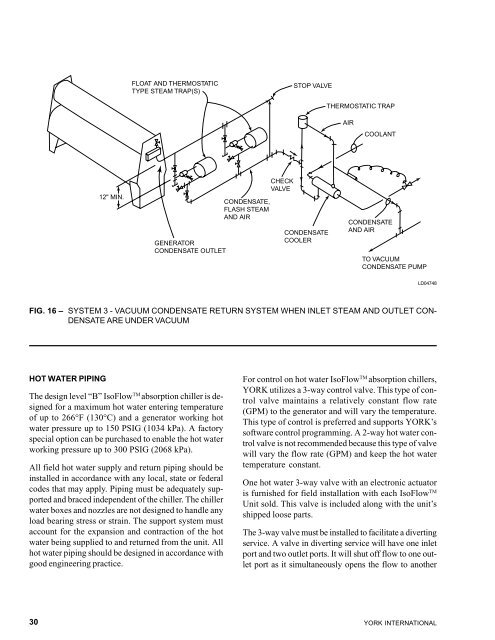

FIG. 16 – SYSTEM 3 - VACUUM CONDENSATE RETURN SYSTEM WHEN INLET STEAM AND OUTLET CON-<br />

DENSATE ARE UNDER VACUUM<br />

HOT WATER PIPING<br />

30<br />

12" MIN.<br />

FLOAT AND THERMOSTATIC<br />

TYPE STEAM TRAP(S)<br />

GENERATOR<br />

CONDENSATE OUTLET<br />

The design level “B” <strong>IsoFlow</strong> TM absorption chiller is designed<br />

for a maximum hot water entering temperature<br />

of up to 266°F (130°C) and a generator working hot<br />

water pressure up to 150 PSIG (1034 kPa). A factory<br />

special option can be purchased to enable the hot water<br />

working pressure up to 300 PSIG (2068 kPa).<br />

All field hot water supply and return piping should be<br />

installed in accordance <strong>with</strong> any local, state or federal<br />

codes that may apply. Piping must be adequately supported<br />

and braced independent of the chiller. The chiller<br />

water boxes and nozzles are not designed to handle any<br />

load bearing stress or strain. The support system must<br />

account for the expansion and contraction of the hot<br />

water being supplied to and returned from the unit. All<br />

hot water piping should be designed in accordance <strong>with</strong><br />

good engineering practice.<br />

CONDENSATE,<br />

FLASH STEAM<br />

AND AIR<br />

CHECK<br />

VALVE<br />

STOP VALVE<br />

CONDENSATE<br />

COOLER<br />

THERMOSTATIC TRAP<br />

AIR<br />

COOLANT<br />

CONDENSATE<br />

AND AIR<br />

TO VACUUM<br />

CONDENSATE PUMP<br />

LD04748<br />

For control on hot water <strong>IsoFlow</strong> TM absorption chillers,<br />

YORK utilizes a 3-way control valve. This type of control<br />

valve maintains a relatively constant flow rate<br />

(GPM) to the generator and will vary the temperature.<br />

This type of control is preferred and supports YORK’s<br />

software control programming. A 2-way hot water control<br />

valve is not recommended because this type of valve<br />

will vary the flow rate (GPM) and keep the hot water<br />

temperature constant.<br />

One hot water 3-way valve <strong>with</strong> an electronic actuator<br />

is furnished for field installation <strong>with</strong> each <strong>IsoFlow</strong> TM<br />

Unit sold. This valve is included along <strong>with</strong> the unit’s<br />

shipped loose parts.<br />

The 3-way valve must be installed to facilitate a diverting<br />

service. A valve in diverting service will have one inlet<br />

port and two outlet ports. It will shut off flow to one outlet<br />

port as it simultaneously opens the flow to another<br />

YORK INTERNATIONAL

![[PDF] •Outdoor installation 4-5 - Johnson Controls](https://img.yumpu.com/10374038/1/184x260/pdf-ooutdoor-installation-4-5-johnson-controls.jpg?quality=85)

![[PDF] The European Products Catalogue 2012 - Johnson Controls](https://img.yumpu.com/3624903/1/184x260/pdf-the-european-products-catalogue-2012-johnson-controls.jpg?quality=85)