Brazilian Journal of Analytical Chemistry - BRJAC - Brazilian Journal ...

Brazilian Journal of Analytical Chemistry - BRJAC - Brazilian Journal ...

Brazilian Journal of Analytical Chemistry - BRJAC - Brazilian Journal ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Eberlin et al.<br />

surface is very irregular, with the appearance <strong>of</strong> an agglomerate<br />

<strong>of</strong> globular and/or cylindrical elements <strong>of</strong> ~ 5<br />

µm or less. Accurate measurement <strong>of</strong> the coating thickness<br />

is not feasible, due to this rough and irregular surface.<br />

Comparing the coated fiber (Figure 2B, fiber thickness<br />

<strong>of</strong> 194 ± 4 µm) with an uncoated fused silica fiber<br />

(Figure 2A, fiber thickness <strong>of</strong> 130 µm), the film thickness<br />

is calculated to be 32 ± 2 µm. Apart from preventing an<br />

accurate estimation <strong>of</strong> thickness, this irregular surface is<br />

an attractive characteristic for a SPME fiber since it leads<br />

to an increase in the surface area <strong>of</strong> the fiber exposed<br />

to analytes or to the vaccuum inside the MS ionization<br />

chamber, allowing faster mass transfer <strong>of</strong> analytes to and<br />

from the fiber. The microstructure <strong>of</strong> the coating can be<br />

inspected after 10k× magnification (Figure 2C), and the<br />

APTMS / PDMS surface appears here as being compact<br />

and non-porous. The material seems to be a cluster <strong>of</strong><br />

scale-like pieces, and no macro- or mesoporous structures<br />

are visible. The lack <strong>of</strong> a pore system can be considered<br />

a drawback since irregular surfaces improve the<br />

performance <strong>of</strong> SPME fibers. But, apparently, the analytical<br />

performance <strong>of</strong> the fiber is not affected by this feature,<br />

as demonstrated elsewhere [16]. The coating also<br />

seems to maintain its integrity even after 200 extraction<br />

and desorption cycles. This endurance is relevant,<br />

since both processes occur under conditions which are<br />

particularly aggressive to SPME fibers: the extraction is<br />

performed by its immersion in acidified media, and the<br />

fiber is directly exposed to heating from the EI filaments.<br />

This robustness, not so typical for conventional fibers, is<br />

typical <strong>of</strong> sol-gel coated SPME fibers, probably due to the<br />

chemical bonding between the coating and the fused<br />

silica support.<br />

fi g u rE 3. sPmE ExtraCtion P r o f i l E o f CP f ro m a q u E o u s s o l u t i o n s (100<br />

µg l -1 ) in Ph 1.<br />

Extraction and MS Signal Pr<strong>of</strong>iles. Figure 3 shows FIMS<br />

(APTMS/PDMS) extraction pr<strong>of</strong>iles for all CP investigated.<br />

Equilibration is reached for periods ranging from<br />

~6 min (PCP, 43CP) to ~13 min (246CP). These results<br />

show that the equilibration is extremely fast, compared<br />

to typical values <strong>of</strong> 60 min or more obtained for CP<br />

with commercial SPME fibers. Such fast equilibration is<br />

characteristic <strong>of</strong> sol-gel coated SPME fibers. Since the<br />

coatings provided by the sol-gel process are thinner,<br />

equilibration with sample is more rapidly achieved, in<br />

comparison with thicker coatings from commercial fibers.<br />

For these results, a time <strong>of</strong> 7.5 min was chosen<br />

as ideal for direct extraction, with the solution pH adjusted<br />

to 1 and with no CP derivatization. The standard<br />

relative deviation presented in CP ranged from 1.4%<br />

to 25%. Considering the extreme extraction and desorption<br />

conditions, and the considerable gains in speed<br />

and simplicity, these values seem quite acceptable.<br />

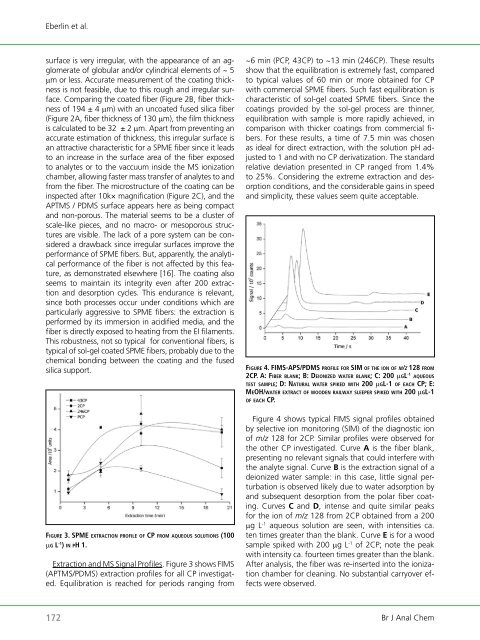

fi g u r E 4. fims-aPs/Pdms P r o f i l E f o r sim o f t h E i o n o f m/z 128 f ro m<br />

2CP. a: fiBEr B l a n k; B: dEionizEd w a t E r B l a n k; C: 200 µgl -1 a q u E o u s<br />

tEst s a m P l E; d: na t u ra l w a t E r sPikEd w i t h 200 µgl-1 o f E a C h CP; E:<br />

mEoh/w a t E r E x t ra C t o f w o o d E n ra i l w a y slEEPEr sPikEd w i t h 200 µgl-1<br />

o f E a C h CP.<br />

Figure 4 shows typical FIMS signal pr<strong>of</strong>iles obtained<br />

by selective ion monitoring (SIM) <strong>of</strong> the diagnostic ion<br />

<strong>of</strong> m/z 128 for 2CP. Similar pr<strong>of</strong>iles were observed for<br />

the other CP investigated. Curve A is the fiber blank,<br />

presenting no relevant signals that could interfere with<br />

the analyte signal. Curve B is the extraction signal <strong>of</strong> a<br />

deionized water sample: in this case, little signal perturbation<br />

is observed likely due to water adsorption by<br />

and subsequent desorption from the polar fiber coating.<br />

Curves C and D, intense and quite similar peaks<br />

for the ion <strong>of</strong> m/z 128 from 2CP obtained from a 200<br />

µg L -1 aqueous solution are seen, with intensities ca.<br />

ten times greater than the blank. Curve E is for a wood<br />

sample spiked with 200 µg L -1 <strong>of</strong> 2CP; note the peak<br />

with intensity ca. fourteen times greater than the blank.<br />

After analysis, the fiber was re-inserted into the ionization<br />

chamber for cleaning. No substantial carryover effects<br />

were observed.<br />

172 Br J Anal Chem