GENERAL Model FE and BE - Geisel

GENERAL Model FE and BE - Geisel

GENERAL Model FE and BE - Geisel

- TAGS

- model

- geisel

- www.gogeisel.com

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

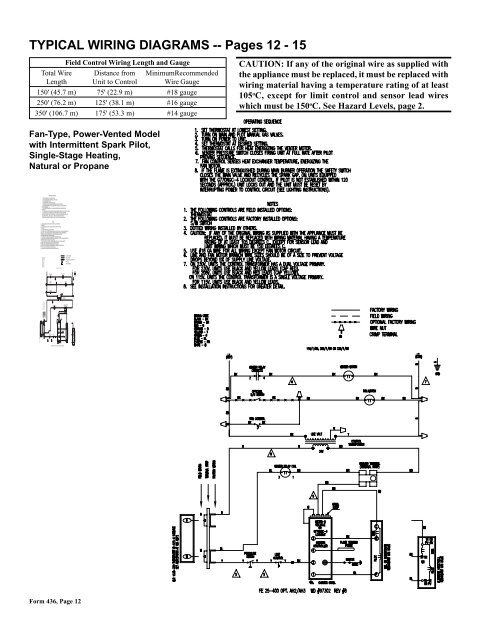

TYPICAL WIRING DIAGRAMS -- Pages 12 - 15<br />

Field Control Wiring Length <strong>and</strong> Gauge<br />

Total Wire Distance from MinimumRecommended<br />

Length Unit to Control Wire Gauge<br />

150' (45.7 m) 75' (22.9 m) #18 gauge<br />

250' (76.2 m) 125' (38.1 m) #16 gauge<br />

350' (106.7 m) 175' (53.3 m) #14 gauge<br />

Fan-Type, Power-Vented <strong>Model</strong><br />

with Intermittent Spark Pilot,<br />

Single-Stage Heating,<br />

Natural or Propane<br />

W.R 1C30-339 THERMOSTAT W-S23-6 SUBBASE<br />

SET ANTICIPATOR AT 0.8 AMPS<br />

OPERATING SEQUENCE<br />

1. SET THERMOSTAT AT LOWEST SETTING.<br />

2. TURN ON MAIN AND PLOT MANUAL GAS VALVES.<br />

3. TURN ON POWER TO UNIT.<br />

4. SET THERMOSTAT AT DESIRED SETTING.<br />

5. THERMOSTAT CALLS FOR HEAT ENERGIZING THE VENTER MOTOR.<br />

6. VENTER PRESSURE SWITCH CLOSES FIRING UNIT AT FULL RATE AFTER PILOT<br />

PROVING SEQUENCE.<br />

7. FAN CONTROL SENSES HEAT EXCHANGER TEMPERATURE, ENERGIZING THE<br />

FAN MOTOR.<br />

8. IF THE FLAME IS EXTINGUISHED DURING MAIN BURNER OPERATION THE SA<strong>FE</strong>TY SWITCH<br />

CLOSES THE MAIN VALVE AND RECYCLES THE SPARK GAP. ON UNITS EQUIPPED<br />

WITH THE G77ONGC-4 LOCKOUT CONTROL, IF PILOT IS NOT ESTABLISHED WITHIN 120<br />

SECONDS (APPROX.) UNIT LOCKS OUT AND THE UNIT MUST <strong>BE</strong> RESET BY<br />

INTERRUPTING POWER TO CONTROL CIRCUIT (SEE LIGHTING INSTRUCTIONS).<br />

NOTES<br />

1. THE FOLLOWING CONTROLS ARE FIELD INSTALLED OPTIONS:<br />

THERMOSTAT<br />

2. THE FOLLOWING CONTROLS ARE FACTORY INSTALLED OPTIONS:<br />

S/W SWITCH<br />

3. DOTTED WIRING INSTALLED BY OTHERS.<br />

4. CAUTION: IF ANY OF THE ORIGINAL WIRING AS SUPPLIED WITH THE APPLIANCE MUST <strong>BE</strong><br />

REPLACED, IT MUST <strong>BE</strong> REPLACED WITH WIRING MATERIAL HAVING A TEMPERATURE<br />

RATING OF AT LEAST 105 DEGREES C., EXCEPT FOR SENSOR LEAD AND<br />

LIMIT WIRING WHICH MUST <strong>BE</strong> 150 DEGREES C.<br />

5. USE #18 GA WIRE FOR ALL WIRING EXCEPT FAN MOTOR CIRCUIT.<br />

6. LINE AND FAN MOTOR BRANCH WIRE SIZES SHOULD <strong>BE</strong> OF A SIZE TO PREVENT VOLTAGE<br />

DROPS <strong>BE</strong>YOND 5% OF SUPPLY LINE VOLTAGE.<br />

7. ON 230V. UNITS THE CONTROL TRANSFORMER HAS A DUAL VOLTAGE PRIMARY.<br />

FOR 230V. UNITS USE BLACK AND YELLOW LEADS (CAP RED).<br />

FOR 208V. UNITS USE BLACK AND RED LEADS (CAP YELLOW).<br />

ON 115V. UNITS THE CONTROL TRANSFORMER IS A SINGLE VOLTAGE PRIMARY.<br />

FOR 115V. UNITS USE BLACK AND YELLOW LEADS.<br />

8. SEE INSTALLATION INSTRUCTIONS FOR GREATER DETAIL.<br />

FACTORY WIRING<br />

WIRING CODE<br />

FIELD WIRING<br />

BLACK - BK<br />

BROWN - BR<br />

OPTIONAL FACTORY WIRING<br />

RED - R<br />

ORANGE - O<br />

WIRE NUT<br />

YELLOW - Y<br />

GREEN - G<br />

CRIMP TERMINAL<br />

BLUE - BL<br />

PURPLE - PR<br />

WHITE - W<br />

115/1/60, 208/1/60 OR 230/1/60<br />

L1<br />

L2<br />

(HOT)<br />

(COM)<br />

VENTER RELAY<br />

VENTER MOTOR<br />

CONTACTS<br />

BK BK<br />

BK<br />

BK<br />

GRD<br />

2 4<br />

6<br />

7<br />

OPTIONAL<br />

FAN MOTOR<br />

S/W SWITCH<br />

BK BK<br />

BK<br />

BK<br />

BK<br />

BK<br />

FIELD WIRING<br />

TERMINAL STRIP<br />

FACTORY WIRING<br />

BK BK<br />

FAN CONTROL<br />

BK BK<br />

BK<br />

LINE VOLT<br />

Y<br />

CONTROL<br />

TRANSFORMER<br />

R<br />

R<br />

BR<br />

24V<br />

8<br />

GROUND TERMINAL<br />

VENTER RELAY COIL<br />

(TERMINAL STRIP)<br />

BL BR BR<br />

3 1<br />

BR<br />

BR<br />

GRND.<br />

W<br />

STRIP<br />

R<br />

R<br />

R<br />

G67BG-5<br />

RECYCLE<br />

C<br />

OR<br />

G770NGC-4<br />

LOCKOUT<br />

BK<br />

3<br />

M<br />

TR OR<br />

IGNITION FLAME SENSING<br />

PV-MV<br />

CONTROLLER PRO<strong>BE</strong><br />

BL<br />

W<br />

4<br />

PRESSURE<br />

LIMIT<br />

BK<br />

W<br />

SWITCH<br />

CONTROL<br />

Y Y Y Y Y<br />

IGNITOR<br />

TH OR<br />

BK<br />

2<br />

MV<br />

GRND<br />

BL<br />

5 5<br />

1<br />

P<br />

BL<br />

CHASSIS GRND.<br />

TH-TR<br />

OR PV<br />

<strong>FE</strong> 25-400 OPT. AH2/AH3 WD #97302 REV #8<br />

Form 436, Page 12<br />

5<br />

R<br />

MAIN<br />

PILOT<br />

W.R. OR RO<strong>BE</strong>RTSHAW<br />

REDUNDANT GAS VALVE<br />

BR<br />

W<br />

G<br />

BR<br />

W<br />

W<br />

BR<br />

PILOT MAIN<br />

ALTERNATE HONEYWELL<br />

REDUNDANT GAS VALVE<br />

CAUTION: If any of the original wire as supplied with<br />

the appliance must be replaced, it must be replaced with<br />

wiring material having a temperature rating of at least<br />

105 o C, except for limit control <strong>and</strong> sensor lead wires<br />

which must be 150 o C. See Hazard Levels, page 2.