Corynebacterium glutamicum - JUWEL - Forschungszentrum Jülich

Corynebacterium glutamicum - JUWEL - Forschungszentrum Jülich

Corynebacterium glutamicum - JUWEL - Forschungszentrum Jülich

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

5.1. Material and Methods<br />

This culture is used to inoculate a second preculture, containing defined medium with<br />

urea (see table 5.2 on page 92) with 1-3% v/v. This culture was allowed to grow for<br />

about 14 hours (usually overnight) after which it was measured and used for inoculation<br />

of the production culture with 1-5% v/v, leading to an initial OD600 of less than 1 in<br />

the production culture. The second preculture was introduced in order to get rid of the<br />

influence of the complex components in the medium.<br />

Stirred Bioreactor<br />

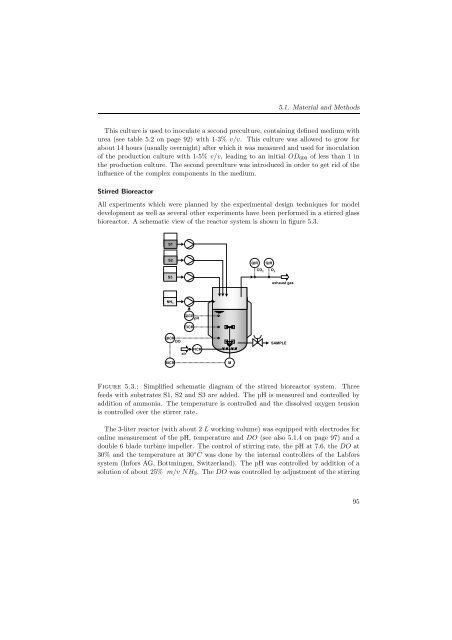

All experiments which were planned by the experimental design techniques for model<br />

development as well as several other experiments have been performed in a stirred glass<br />

bioreactor. A schematic view of the reactor system is shown in figure 5.3.<br />

S1<br />

S2<br />

S3<br />

NH 3<br />

QICR<br />

DO<br />

SICR<br />

QICR<br />

pH<br />

air<br />

TICR<br />

FICR<br />

M<br />

QIR QIR<br />

CO 2<br />

O 2<br />

exhaust gas<br />

SAMPLE<br />

Figure 5.3.: Simplified schematic diagram of the stirred bioreactor system. Three<br />

feeds with substrates S1, S2 and S3 are added. The pH is measured and controlled by<br />

addition of ammonia. The temperature is controlled and the dissolved oxygen tension<br />

is controlled over the stirrer rate.<br />

The 3-liter reactor (with about 2 L working volume) was equipped with electrodes for<br />

online measurement of the pH, temperature and DO (see also 5.1.4 on page 97) and a<br />

double 6 blade turbine impeller. The control of stirring rate, the pH at 7.6, the DO at<br />

30% and the temperature at 30 ◦ C was done by the internal controllers of the Labfors<br />

system (Infors AG, Bottmingen, Switzerland). The pH was controlled by addition of a<br />

solution of about 25% m/v NH3. TheDO was controlled by adjustment of the stirring<br />

95