Download pdf - CIB-W18

Download pdf - CIB-W18

Download pdf - CIB-W18

- TAGS

- download

- cib-w18.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

carrying capacity of steel bolts in end-grain under lateral loading can sufficiently<br />

accurate be calculated by using the formula given in the paper.<br />

25-7-2 J Ehlbeck, H Werner<br />

Softwood and hardwood embedding strength for dowel-type fasteners,<br />

Background of the formulae in Eurocode 5<br />

Introduction<br />

The embedding strength of timber and wood-based materials as well as the<br />

yield moment of the fasteners are (besides the joint's geometry) governing<br />

properties for determining the load-carrying capacities of joints with dowel-type<br />

fasteners. The embedding strength depends on the type of fastener,<br />

the joint configuration (such as member thicknesses, end and edge distances<br />

as well as spacing of the fasteners), the manufacturing of the joint<br />

(e.g. predrilled holes), and the wood species or the quality of the woodbased<br />

materials. Thus, the embedding strength is not a special material<br />

property, but a system property.<br />

Many research works have been done to describe this property and to<br />

collect sufficient test data. The test methods used differed, however, in<br />

many cases significantly so that the results can not be compared without<br />

any reservation. It was therefore an important task of the responsible European<br />

standardization committee to produce a test standard EN 383<br />

"Timber Structures - Test Methods - Determination of Embedding<br />

Strength and Foundation Values for Dowel-type Fasteners".<br />

The embedding strength of some hardwoods was tested according to<br />

this European, harmonized test method. The tests were made under different<br />

load-grain angles using bolts and dowels. Additional tests were performed<br />

with European whitewood (picea abies) under 90° load-grain angle.<br />

When evaluating all test data, the results published by [Whale and<br />

Smith, 1986 a and b] were also used because these tests under loading parallel<br />

to grain were in line with the main principles of EN 383.<br />

Conclusions<br />

The variance of the embedding strength of hardwoods (coefficient of variation<br />

15%) is larger than the variance of the hardwood densities (coeffi-<br />

cient of variation 8%). This taking into account, the characteristic embed-<br />

f , can be derived assuming a Gaussian distribution:<br />

ding strength, hk ,<br />

Hardwood, parallel to grain<br />

� �<br />

f � 0,09 � 1� 0,01d<br />

�<br />

h,0, k k<br />

Hardwood, perpendicular to grain<br />

� �<br />

f � 0,09 � 1� 0,016d<br />

�<br />

h,0, k k<br />

f h,0<br />

embedding strength parallel to grain, N/mm 2<br />

f h,90<br />

embedding strength perpendicular to grain, N/mm 2<br />

� k characteristic density, kg/m 3<br />

d fastener diameter, mm<br />

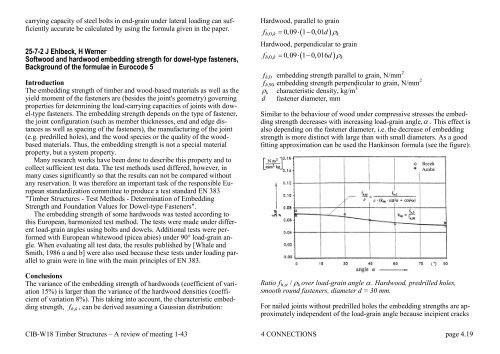

Similar to the behaviour of wood under compressive stresses the embedding<br />

strength decreases with increasing load-grain angle,� . This effect is<br />

also depending on the fastener diameter, i.e. the decrease of embedding<br />

strength is more distinct with large than with small diameters. As a good<br />

fitting approximation can be used the Hankinson formula (see the figure):<br />

Ratio fh, � / �kover load-grain angle � � . Hardwood, predrilled holes,<br />

smooth round fasteners, diameter d = 30 mm.<br />

For nailed joints without predrilled holes the embedding strengths are approximately<br />

independent of the load-grain angle because incipient cracks<br />

<strong>CIB</strong>-<strong>W18</strong> Timber Structures – A review of meeting 1-43 4 CONNECTIONS page 4.19