Download pdf - CIB-W18

Download pdf - CIB-W18

Download pdf - CIB-W18

- TAGS

- download

- cib-w18.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

4.11 NON-METALLIC DOWELS<br />

22-7-3 J Ehlbeck, O Eberhart<br />

Design of double shear joints with non-metallic dowels. A proposal for<br />

a supplement of the design concept<br />

Introduction<br />

At the University of Karlsruhe a research programme was undertaken to<br />

determine the load-carrying capacity and the deformation behaviour of<br />

glulam joints with non-metallic dowels of resin-impregnated compressed<br />

wood. This material consists of multi-layered densified 2 mm beech veneers<br />

glued together and fully impregnated with phenolic resins. One of<br />

the objectives of this research work was to find out if Johansen's theory for<br />

determining the ultimate load-carrying capacity of joints with dowel-type<br />

fasteners can also be applied for such type of material having pronounced<br />

brittle properties.<br />

The test data in principle confirmed the applicability of this design<br />

model which was introduced in the <strong>CIB</strong>-Code as well as the draft Eurocode<br />

5 for limit state design calculations. It turned out, however, that an<br />

additional failure mode may occur which makes it advisable to introduce a<br />

supplementary design formula.<br />

Conclusions<br />

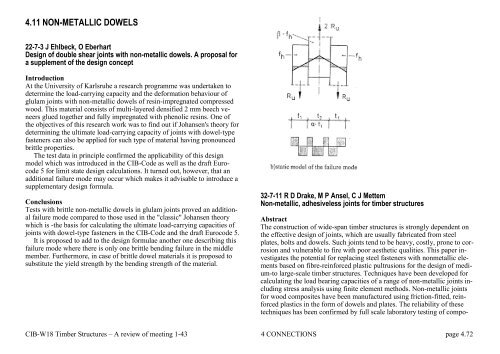

Tests with brittle non-metallic dowels in glulam joints proved an additional<br />

failure mode compared to those used in the "classic" Johansen theory<br />

which is -the basis for calculating the ultimate load-carrying capacities of<br />

joints with dowel-type fasteners in the <strong>CIB</strong>-Code and the draft Eurocode 5.<br />

It is proposed to add to the design formulae another one describing this<br />

failure mode where there is only one brittle bending failure in the middle<br />

member. Furthermore, in case of brittle dowel materials it is proposed to<br />

substitute the yield strength by the bending strength of the material.<br />

32-7-11 R D Drake, M P Ansel, C J Mettem<br />

Non-metallic, adhesiveless joints for timber structures<br />

Abstract<br />

The construction of wide-span timber structures is strongly dependent on<br />

the effective design of joints, which are usually fabricated from steel<br />

plates, bolts and dowels. Such joints tend to be heavy, costly, prone to corrosion<br />

and vulnerable to fire with poor aesthetic qualities. This paper investigates<br />

the potential for replacing steel fasteners with nonmetallic elements<br />

based on fibre-reinforced plastic pultrusions for the design of medium-to<br />

large-scale timber structures. Techniques have been developed for<br />

calculating the load bearing capacities of a range of non-metallic joints including<br />

stress analysis using finite element methods. Non-metallic joints<br />

for wood composites have been manufactured using friction-fitted, reinforced<br />

plastics in the form of dowels and plates. The reliability of these<br />

techniques has been confirmed by full scale laboratory testing of compo-<br />

<strong>CIB</strong>-<strong>W18</strong> Timber Structures – A review of meeting 1-43 4 CONNECTIONS page 4.72