You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

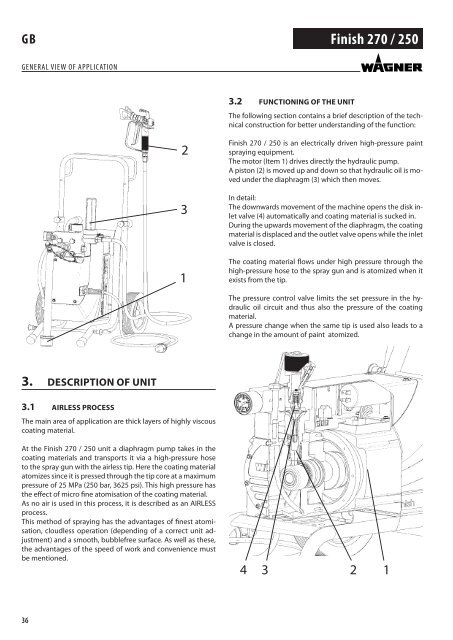

GB<strong>Finish</strong> <strong>270</strong> / <strong>250</strong>general view of appliCation3.2 fuNCTIONING Of ThE uNITThe following section contains a brief description of the technicalconstruction for better understanding of the function:231<strong>Finish</strong> <strong>270</strong> / <strong>250</strong> is an electrically driven high-pressure paintspraying equipment.The motor (Item 1) drives directly the hydraulic pump.A piston (2) is moved up and down so that hydraulic oil is movedunder the diaphragm (3) which then moves.In detail:The downwards movement of the machine opens the disk inletvalve (4) automatically and coating material is sucked in.During the upwards movement of the diaphragm, the coatingmaterial is displaced and the outlet valve opens while the inletvalve is closed.The coating material flows under high pressure through thehigh-pressure hose to the spray gun and is atomized when itexists from the tip.The pressure control valve limits the set pressure in the hydraulicoil circuit and thus also the pressure of the coatingmaterial.A pressure change when the same tip is used also leads to achange in the amount of paint atomized.3. DESCRIpTION Of uNIT3.1 AIRlESS pROCESSThe main area of application are thick layers of highly viscouscoating material.At the <strong>Finish</strong> <strong>270</strong> / <strong>250</strong> unit a diaphragm pump takes in thecoating materials and transports it via a high-pressure hoseto the spray gun with the airless tip. Here the coating materialatomizes since it is pressed through the tip core at a maximumpressure of 25 MPa (<strong>250</strong> bar, 3625 psi). This high pressure hasthe effect of micro fine atomisation of the coating material.As no air is used in this process, it is described as an AIRLESSprocess.This method of spraying has the advantages of finest atomisation,cloudless operation (depending of a correct unit adjustment)and a smooth, bubblefree surface. As well as these,the advantages of the speed of work and convenience mustbe mentioned.4 3 2 136