Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

90<br />

ENGLISH<br />

KONFEKSİYON TEKNİK<br />

NİSAN | APRIL | 20<strong>18</strong><br />

round off the product presentation. Each of<br />

the four acrylic glass machines has individually<br />

removable elements for detailed viewing. A<br />

special highlight at the booth will be the live<br />

presentation of the online Customer Portal Knitting,<br />

which offers an enhanced digital product<br />

catalog as well as a lot of information about the<br />

Knitting technologies. Additionally, the platform<br />

is equipped with an easily accessible, permanently<br />

growing knowledge data base.<br />

In the product area Weaving, Groz-Beckert will<br />

among others present the quick and universal<br />

warp tying machine KnotMaster AS/3 at the<br />

ITM. An advantage of the high-performance<br />

knotting machine is its service and maintenance<br />

friendliness. Touch screen control makes<br />

operation easy. With four tying methods, single<br />

knots, automatic repetition, doubles detector<br />

and yarn break detector the AS/3 provides many<br />

useful features and, with its widespread range of<br />

applications, it is one of the bestsellers among<br />

the standard versions. In addition, the knotting<br />

machine is capable of handling a large variety<br />

of different yarns like cotton, wool, synthetic as<br />

well as blended and elastic yarns.<br />

In the product area Felting, the jet strip model Hy-<br />

Tec ® P will occupy center stage. Its improved handling<br />

through optimized elasticity leads to a higher<br />

service life of the jet strip. Furthermore, the higher<br />

scratch resistance of HyTec ® P prevents it from<br />

damages when being inserted into the machine.<br />

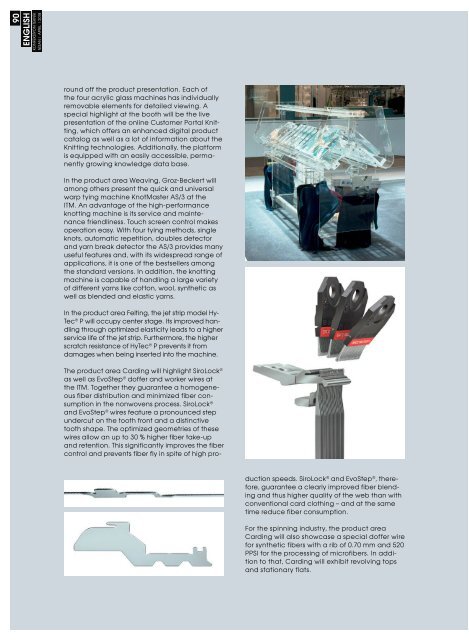

The product area Carding will highlight SiroLock ®<br />

as well as EvoStep ® doffer and worker wires at<br />

the ITM. Together they guarantee a homogeneous<br />

fiber distribution and minimized fiber consumption<br />

in the nonwovens process. SiroLock ®<br />

and EvoStep ® wires feature a pronounced step<br />

undercut on the tooth front and a distinctive<br />

tooth shape. The optimized geometries of these<br />

wires allow an up to 30 % higher fiber take-up<br />

and retention. This significantly improves the fiber<br />

control and prevents fiber fly in spite of high production<br />

speeds. SiroLock ® and EvoStep ® , therefore,<br />

guarantee a clearly improved fiber blending<br />

and thus higher quality of the web than with<br />

conventional card clothing – and at the same<br />

time reduce fiber consumption.<br />

For the spinning industry, the product area<br />

Carding will also showcase a special doffer wire<br />

for synthetic fibers with a rib of 0.70 mm and 520<br />

PPSI for the processing of microfibers. In addition<br />

to that, Carding will exhibit revolving tops<br />

and stationary flats.