You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

İNCELEME<br />

67<br />

Dosing in [ml/kg] implicates a system that is<br />

adding an amount of chemicals in the impregnating<br />

bath proportional to the weight of<br />

fabric. A change of speed and/or a change<br />

of fabric will immediately adapt the amount<br />

of chemicals in order to reach the desired<br />

amounts of chemicals on the fabric specified<br />

by the recipe in [ml/kg].<br />

All systems that exist worldwide belong to one<br />

of the two categories specified hereunder:<br />

- the dosing “related to the fabric”<br />

- the dosing “related to the feeding”<br />

Both systems are dosing in [ml/kg] and thus<br />

dosing related to the fabric. They only differ<br />

in the way how they calculate the necessary<br />

amounts of chemicals. The system “dosing<br />

related to the fabric” is calculating the amounts<br />

of chemicals proportional to the passing fabric,<br />

whereas the system “dosing related to the feeding”<br />

is calculating the amounts of chemicals<br />

related to the used amount of liquid. In the end,<br />

provided the systems are fitted with the needed<br />

technical items, the correct software and a perfect<br />

setting, both systems will give an identical<br />

outcome of the needed [ml/kg] on the fabric.<br />

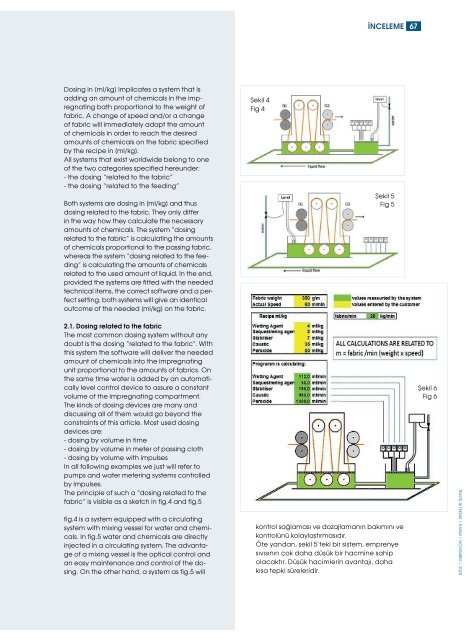

Şekil 4<br />

Fig 4<br />

Şekil 5<br />

Fig 5<br />

2.1. Dosing related to the fabric<br />

The most common dosing system without any<br />

doubt is the dosing “related to the fabric”. With<br />

this system the software will deliver the needed<br />

amount of chemicals into the impregnating<br />

unit proportional to the amounts of fabrics. On<br />

the same time water is added by an automatically<br />

level control device to assure a constant<br />

volume of the impregnating compartment.<br />

The kinds of dosing devices are many and<br />

discussing all of them would go beyond the<br />

constraints of this article. Most used dosing<br />

devices are:<br />

- dosing by volume in time<br />

- dosing by volume in meter of passing cloth<br />

- dosing by volume with impulses<br />

In all following examples we just will refer to<br />

pumps and water metering systems controlled<br />

by impulses.<br />

The principle of such a “dosing related to the<br />

fabric” is visible as a sketch in fig.4 and fig.5<br />

fig.4 is a system equipped with a circulating<br />

system with mixing vessel for water and chemicals.<br />

In fig.5 water and chemicals are directly<br />

injected in a circulating system. The advantage<br />

of a mixing vessel is the optical control and<br />

an easy maintenance and control of the dosing.<br />

On the other hand, a system as fig.5 will<br />

kontrol sağlaması ve dozajlamanın bakımını ve<br />

kontrolünü kolaylaştırmasıdır.<br />

Öte yandan, şekil 5’teki bir sistem, emprenye<br />

sıvısının çok daha düşük bir hacmine sahip<br />

olacaktır. Düşük hacimlerin avantajı, daha<br />

kısa tepki süreleridir.<br />

Şekil 6<br />

Fig 6<br />

TEKSTİL & TEKNİK | KASIM | NOVEMBER | <strong>2020</strong>