Hydraulikpresse 2 | 2011 - Hansa Flex

Hydraulikpresse 2 | 2011 - Hansa Flex

Hydraulikpresse 2 | 2011 - Hansa Flex

Sie wollen auch ein ePaper? Erhöhen Sie die Reichweite Ihrer Titel.

YUMPU macht aus Druck-PDFs automatisch weboptimierte ePaper, die Google liebt.

a luxury holiday. during the journeys, which were split into summer and winter<br />

‘cruises’, participants really were required to get on board.<br />

HisTorical new Build<br />

but now it has all come to an end, at least in the short term – given that the maintenance<br />

costs for the three-master were increasing year on year. building a new<br />

ship would prove more economical, and so the dsst commissioned brenn- und<br />

verformtechnik bremen gmbh (bvt) to build a new tall ship – the first in more<br />

than 50 years to be built in germany. bvt has more than 20,000 square metres of<br />

space at its disposal at its main manufacturing site in bremen. it is here that sections<br />

of ship and steel constructions are built, each weighing up to 1,500 tonnes.<br />

the shipbuilders here have completed more than a dozen ship extensions since<br />

2004, along with other projects.<br />

all aBouT cuTTinG and mouldinG<br />

bvt will mould almost 400 tonnes of steel in rebuilding the ‘alexander ii’ such<br />

that they can later be welded together to form a ship. since we know that can’t<br />

be as easy as it sounds, we in february <strong>2011</strong> visited the site of what used to be<br />

vulkan-Werft in the vegesack area of bremen in order to form our own opinion.<br />

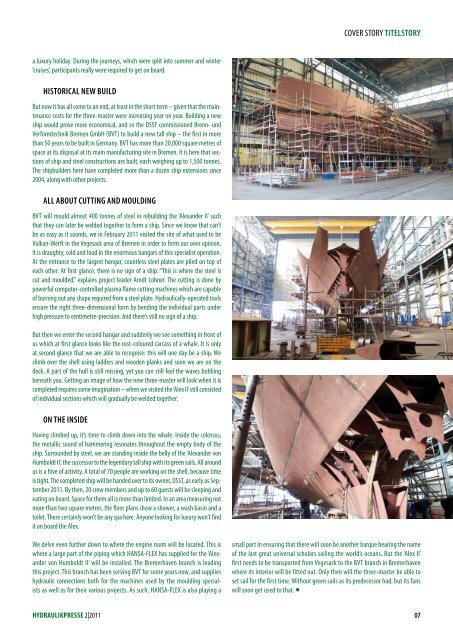

it is draughty, cold and loud in the enormous hangars of this specialist operation.<br />

at the entrance to the largest hangar, countless steel plates are piled on top of<br />

each other. at first glance, there is no sign of a ship. “this is where the steel is<br />

cut and moulded,” explains project leader arndt Lohner. the cutting is done by<br />

powerful computer-controlled plasma flame cutting machines which are capable<br />

of burning out any shape required from a steel plate. hydraulically-operated tools<br />

ensure the right three-dimensional form by bending the individual parts under<br />

high pressure to centimetre-precision. and there’s still no sign of a ship.<br />

but then we enter the second hangar and suddenly we see something in front of<br />

us which at first glance looks like the rust-coloured carcass of a whale. it is only<br />

at second glance that we are able to recognise: this will one day be a ship. We<br />

climb over the shell using ladders and wooden planks and soon we are on the<br />

deck. a part of the hull is still missing, yet you can still feel the waves bobbing<br />

beneath you. getting an image of how the new three-master will look when it is<br />

completed requires some imagination – when we visited the ‘alex ii’ still consisted<br />

of individual sections which will gradually be welded together.<br />

on THe inside<br />

having climbed up, it’s time to climb down into the whale. inside the colossus,<br />

the metallic sound of hammering resonates throughout the empty body of the<br />

ship. surrounded by steel, we are standing inside the belly of the ‘alexander von<br />

humboldt ii’, the successor to the legendary tall ship with its green sails. all around<br />

us is a hive of activity. A total of 70 people are working on the shell, because time<br />

is tight. the completed ship will be handed over to its owner, dsst, as early as september<br />

<strong>2011</strong>. by then, 20 crew members and up to 60 guests will be sleeping and<br />

eating on board. space for them all is more than limited. in an area measuring not<br />

more than two square metres, the floor plans show a shower, a wash basin and a<br />

toilet. there certainly won’t be any spa here. anyone looking for luxury won’t find<br />

it on board the alex.<br />

We delve even further down to where the engine room will be located. this is<br />

where a large part of the piping which hansa-fLeX has supplied for the ‘alexander<br />

von humboldt ii’ will be installed. the bremerhaven branch is leading<br />

this project. this branch has been serving bvt for some years now, and supplies<br />

hydraulic connections both for the machines used by the moulding specialists<br />

as well as for their various projects. as such, hansa-fLeX is also playing a<br />

HYDRAULIKPRESSE 2|<strong>2011</strong><br />

cover story TiTelsTory<br />

small part in ensuring that there will soon be another barque bearing the name<br />

of the last great universal scholars sailing the world’s oceans. but the ‘alex ii’<br />

first needs to be transported from vegesack to the bvt branch in bremerhaven<br />

where its interior will be fitted out. only then will the three-master be able to<br />

set sail for the first time. Without green sails as its predecessor had, but its fans<br />

will soon get used to that. ¡<br />

07