PRODUCTION Of NUTRIENT SOURCES FOR RHIZOBIUM

PRODUCTION Of NUTRIENT SOURCES FOR RHIZOBIUM

PRODUCTION Of NUTRIENT SOURCES FOR RHIZOBIUM

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

���<br />

explained that the correlation between growth rate and stress sensitivity such that cells growing<br />

quickly in a glucose-rich medium are more sensitive to heat (Walker, 1998). Glycerol acted as the<br />

compatible solutes in high osmotic pressure condition such as high salt concentration and high sugar<br />

concentration. A little amounts of reducing sugars in this experiment was not enough to enhanced the<br />

high glycerol production by yeast. Interestingly, the starch was vigorously utilized, it might correlated<br />

to the amylase enzyme that released to catch with substrate. Thus, from this study is necessary for<br />

further experiment.<br />

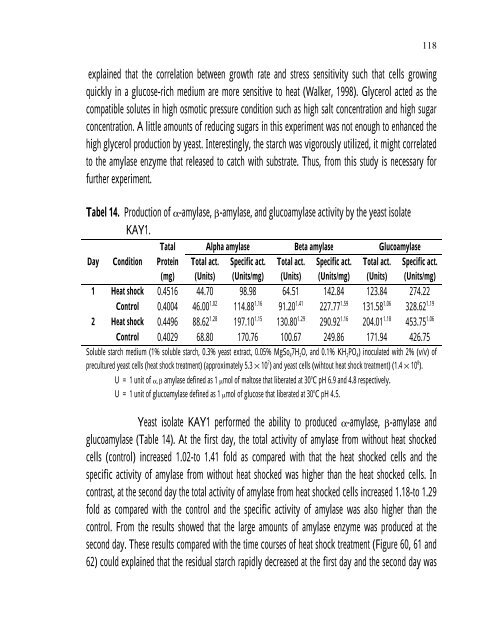

Tabel 14. Production of α-amylase, β-amylase, and glucoamylase activity by the yeast isolate<br />

KAY1.<br />

Tatal Alpha amylase Beta amylase Glucoamylase<br />

Day Condition Protein Total act. Specific act. Total act. Specific act. Total act. Specific act.<br />

(mg) (Units) (Units/mg) (Units) (Units/mg) (Units) (Units/mg)<br />

1 Heat shock 0.4516 44.70 98.98 64.51 142.84 123.84 274.22<br />

Control 0.4004 46.001.02 114.881.16 91.201.41 227.771.59 131.581.06 328.621.19 2 Heat shock 0.4496 88.621.28 197.101.15 130.801.29 290.921.16 204.011.18 453.751.06 Control 0.4029 68.80 170.76 100.67 249.86 171.94 426.75<br />

Soluble starch medium (1% soluble starch, 0.3% yeast extract, 0.05% MgSo47H2O, and 0.1% KH2PO4) inoculated with 2% (v/v) of<br />

precultured yeast cells (heat shock treatment) (approximately 5.3 × 10 7 ) and yeast cells (wihtout heat shock treatment) (1.4 × 10 8 ).<br />

U = 1 unit of α, β amylase defined as 1 µmol of maltose that liberated at 30 o C pH 6.9 and 4.8 respectively.<br />

U = 1 unit of glucoamylase defined as 1 µmol of glucose that liberated at 30 o C pH 4.5.<br />

Yeast isolate KAY1 performed the ability to produced α-amylase, β-amylase and<br />

glucoamylase (Table 14). At the first day, the total activity of amylase from without heat shocked<br />

cells (control) increased 1.02-to 1.41 fold as compared with that the heat shocked cells and the<br />

specific activity of amylase from without heat shocked was higher than the heat shocked cells. In<br />

contrast, at the second day the total activity of amylase from heat shocked cells increased 1.18-to 1.29<br />

fold as compared with the control and the specific activity of amylase was also higher than the<br />

control. From the results showed that the large amounts of amylase enzyme was produced at the<br />

second day. These results compared with the time courses of heat shock treatment (Figure 60, 61 and<br />

62) could explained that the residual starch rapidly decreased at the first day and the second day was