these Open Championship Clubs choose to relief grind - Pitchcare

these Open Championship Clubs choose to relief grind - Pitchcare

these Open Championship Clubs choose to relief grind - Pitchcare

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

also of the RFU and a number of<br />

insurance companies. Within Regulation<br />

22, it clearly states that maintenance is a<br />

necessity, and that proof of maintenance<br />

must be demonstrated <strong>to</strong> an appropriate<br />

Test Institute at repeated intervals.<br />

Artificial rugby pitches must be analysed<br />

by Test Institutes on a regular basis <strong>to</strong><br />

ensure that they continue <strong>to</strong> meet the<br />

performance requirements of English<br />

rugby’s governing body.<br />

In conjunction with the FA and the<br />

Football Foundation, the RFU has also<br />

developed a Framework Agreement for<br />

the Provision of Artificial Grass Pitches.<br />

Within this, particular focus is given <strong>to</strong><br />

the need for pitches installed under this<br />

scheme <strong>to</strong> satisfy certain performance<br />

criteria, <strong>to</strong> ensure a high standard of<br />

playing surface is provided <strong>to</strong> end users.<br />

From a maintenance perspective, the<br />

pitch manufacturers are required <strong>to</strong><br />

identify the individual maintenance<br />

needs of each artificial surface, based on<br />

determining fac<strong>to</strong>rs including pitch size<br />

and projected usage levels. The<br />

Framework Agreement further stipulates<br />

that the programme of maintenance<br />

must be reviewed regularly, and should<br />

be revised <strong>to</strong> reflect any changes in usage<br />

levels or pitch performance. In line with<br />

an overall emphasis on quality control, a<br />

suitable maintenance programme is<br />

considered a prerequisite <strong>to</strong> ensuring a<br />

pitch’s compliance with the<br />

manufacturer’s warranty.<br />

So, what measures can be put in place<br />

<strong>to</strong> reduce the risk of injury on an<br />

artificial sports pitch, thereby minimising<br />

the likelihood of a compensation claim?<br />

As mentioned previously, some<br />

preventative actions can be put in place<br />

by the owners and opera<strong>to</strong>rs of artificial<br />

pitches, such as taking out suitable<br />

insurance cover and familiarisation with<br />

the conditions of the warranty. However,<br />

the majority of the work involved in<br />

ensuring a pitch is ‘fit for purpose’ will<br />

fall within the remit of the grounds team,<br />

and, whilst accidents will always happen,<br />

they can often be prevented by ensuring<br />

that those charged with the day-<strong>to</strong>-day<br />

running of an artificial pitch are fully<br />

equipped with the necessary knowledge<br />

and resources <strong>to</strong> implement best<br />

practice, in accordance with industry<br />

guidelines.<br />

In my experience, the basis of any<br />

good maintenance regime for a grounds<br />

team is preparation and forward<br />

planning. Establish a routine of daily, inhouse<br />

inspections <strong>to</strong> familiarise yourself<br />

with your artificial pitch and help you<br />

identify and address any minor issues<br />

before they become major problems.<br />

Torn or ripped carpet poses a<br />

potential trip hazard <strong>to</strong> users of the<br />

facility; a lifted seam can be re-stuck for<br />

much less than it will cost <strong>to</strong> replace a<br />

full seam, and with less hassle, <strong>to</strong>o.<br />

Regular drag brushing forms the<br />

backbone of any maintenance<br />

programme, and can be completed by<br />

pulling a suitable brush, rake or mat over<br />

the surface using a trac<strong>to</strong>r. This helps <strong>to</strong><br />

redistribute any infill which has become<br />

displaced through general play, whilst<br />

also helping <strong>to</strong> lift the carpet fibres. The<br />

Artificial Surfaces<br />

“For an artificial pitch <strong>to</strong> conform <strong>to</strong><br />

BS 7044, it must successfully pass a<br />

series of tests, including ball roll<br />

and rebound, traction, abrasion<br />

resistance and tensile strength”<br />

industry standard is for this process <strong>to</strong> be<br />

carried out, as a minimum, on a weekly<br />

basis.<br />

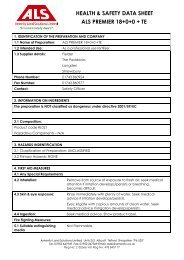

Alongside <strong>these</strong> everyday tasks, it is<br />

important <strong>to</strong> utilise the services of a<br />

maintenance company <strong>to</strong> complete the<br />

more specialist works on your artificial<br />

sports pitch. It is worthwhile choosing<br />

the right company <strong>to</strong> work with, as the<br />

quality of both the service provided and<br />

the works completed can, in the right<br />

hands, give you greater assurance that<br />

your facility will remain in the best<br />

possible condition. A range of criteria<br />

can help you <strong>to</strong> determine the suitability<br />

of a maintenance provider, including<br />

their method statements and risk<br />

assessments for all the services they offer,<br />

their health and safety policy, financial<br />

stability, quality management systems<br />

certification, and any industry<br />

memberships and accreditations.<br />

Cost is also an important<br />

consideration, particularly in the current<br />

climate, but as with all things in life, you<br />

get what you pay for, and it is well worth<br />

investing in the long-term maintenance<br />

of your artificial pitch, as the rewards<br />

that you reap will be that much greater,<br />

whilst the risk of damage and injury will<br />

lessen accordingly.<br />

The basis of a regular contract with<br />

your specialist maintenance provider<br />

should focus on the regular removal of<br />

the accrued dirt, debris and<br />

contamination that can bed in amongst<br />

the granular infill. A hardened or<br />

compacted infill can impact greatly on<br />

ball roll and bounce, as well as the feel of<br />

FEBRUARY/MARCH 2012 PC 55