Xcell Journal Issue 78: Charge to Market with Xilinx 7 Series ...

Xcell Journal Issue 78: Charge to Market with Xilinx 7 Series ...

Xcell Journal Issue 78: Charge to Market with Xilinx 7 Series ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

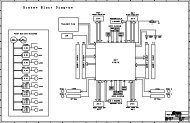

XCELLENCE IN AUTOMOTIVE APPLICATIONS<br />

RTE<br />

BSW<br />

GPIO registers<br />

output<br />

enable<br />

SAFETY<br />

SHELL<br />

out in<br />

SAFETY-RELATED PATH<br />

<strong>to</strong> extend the MCU inputs and outputs<br />

<strong>with</strong> external chips that perform<br />

the parallel-serial data conversion,<br />

like digital shift registers or<br />

analog multiplexers. An FPGA lets<br />

you skip all these satellite components,<br />

reducing thus the bill of materials<br />

as well as the PCB dimensions<br />

of the electronic board.<br />

State-of-the-art FPGA devices<br />

already incorporate analog-<strong>to</strong>-digital<br />

converters. This feature is interesting<br />

in au<strong>to</strong>motive design since many<br />

ECUs make use of analog signals (for<br />

example, battery voltage) <strong>to</strong> implement<br />

part of the needed functionality.<br />

The presence of ADCs in programmable<br />

logic devices opens new application<br />

fields for FPGAs.<br />

Like MCUs, FPGAs offer remote<br />

update capability. However, it is<br />

important <strong>to</strong> note that in this case, the<br />

bitstream downloaded in<strong>to</strong> the FPGA<br />

relates not only <strong>to</strong> software code but<br />

also <strong>to</strong> hardware circuitry. This means<br />

output<br />

enable<br />

RTE<br />

BSW<br />

GPIO registers<br />

out in<br />

that, once the product is in production,<br />

it is still possible <strong>to</strong> change the hardware<br />

design by means of system<br />

updates or upgrades. The au<strong>to</strong>motive<br />

industry appreciates such flexibility,<br />

since it also enables bug fixes (in this<br />

case, both hardware and software) after<br />

the product launch.<br />

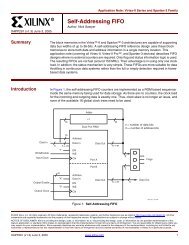

In any ECU that embeds a function<br />

qualified as safety-relevant under ISO<br />

26262, the hardware and software<br />

involved in this implementation must<br />

fulfill a certain level of protection<br />

depending on how it is categorized.<br />

From the software point of view, it is<br />

necessary <strong>to</strong> demonstrate freedom<br />

from interference—that is, the nonsafety-relevant<br />

code running in an<br />

ECU must not corrupt the operation of<br />

any code inside the same ECU classified<br />

as safety-relevant. This isolation is<br />

necessary <strong>to</strong> guarantee correct execution<br />

of safety-related and non-safetyrelated<br />

functions running side-by-side<br />

on the same processor. Often, it’s easi-<br />

er <strong>to</strong> manage these measures more<br />

flexibly in programmable logic than<br />

in MCUs.<br />

Regarding memory protection<br />

strategies oriented <strong>to</strong> functional safety,<br />

it is necessary <strong>to</strong> guarantee write<br />

access <strong>to</strong> certain safety-related signals<br />

only from authorized safety software<br />

components. In the context of MCU<br />

devices, memory partitioning provides<br />

a fault-containment technique <strong>to</strong> separate<br />

software applications from each<br />

other <strong>to</strong> avoid any data corruption<br />

among them. Programmable logic will<br />

likely make it possible <strong>to</strong> implement a<br />

more efficient self-protection mechanism.<br />

It is possible <strong>to</strong> manage the RTE<br />

buffer related <strong>to</strong> safety signals through<br />

dedicated single dual-port memories<br />

so that the data is written from the<br />

write port and read from the read port.<br />

In this way, it is possible <strong>to</strong> implement<br />

dedicated hardware controllers that<br />

put different restrictions on writing or<br />

reading those signals from the software<br />

side. The same approach can be<br />

implemented <strong>with</strong> registers.<br />

The possibility of introducing cus<strong>to</strong>m<br />

hardware solutions in the ECU<br />

system is a big advantage of the FPGA<br />

approach, especially for safety-related<br />

features. In this case, <strong>with</strong> regard <strong>to</strong><br />

I/O pins and GPIO controllers, the<br />

pinout involved in safety functions can<br />

be grouped in made-<strong>to</strong>-measure I/O<br />

ports that are accessed exclusively by<br />

safety components inside the ECU,<br />

separated from the remaining pins of<br />

the device. This is a good way <strong>to</strong><br />

decouple the safety-critical pins from<br />

the non-safety-critical pins of the system,<br />

ensuring freedom from interference<br />

by design. Any access <strong>to</strong> nonsafety<br />

pins cannot corrupt the status<br />

of the safety pins, which are managed<br />

by safety-relevant code only. This idea<br />

is depicted in Figure 4.<br />

Furthermore, it’s also possible <strong>to</strong><br />

tailor the size of each GPIO port <strong>to</strong> the<br />

needs of the application or the software<br />

component that handles it, skipping<br />

the step of converting a GPIO port<br />

in<strong>to</strong> a physical resource that different<br />

26 <strong>Xcell</strong> <strong>Journal</strong> First Quarter 2012<br />

SW<br />

HW<br />

Figure 4 – Hardware/software co-design of a safety shell architecture isolates the safetyrelevant<br />

ports from non-safety ports <strong>to</strong> guarantee there will be no interference.