Jul 2012 - Issue 5 - National Federation of Fish Friers

Jul 2012 - Issue 5 - National Federation of Fish Friers

Jul 2012 - Issue 5 - National Federation of Fish Friers

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

aises the box to ensure none <strong>of</strong> the potatoes are subjected to more than a 30<br />

cm drop to prevent bruising. These boxes are issued a goods received number<br />

(GRN) and stacked in the climate controlled stores. Each box from the bulker<br />

is given the same GRN number and the quality control process and variety is<br />

used to determine what product each GRN is suitable for.<br />

Processing<br />

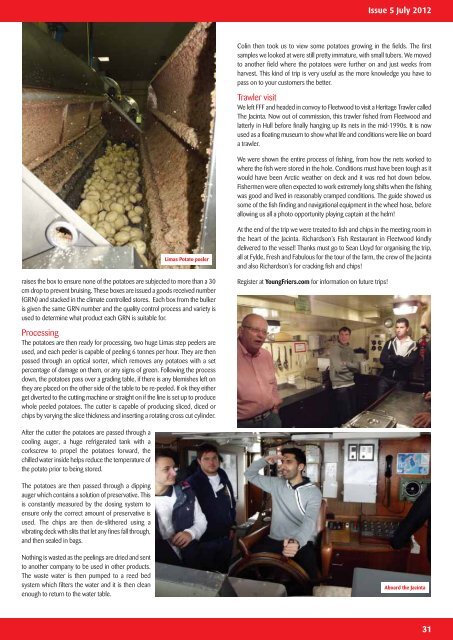

The potatoes are then ready for processing, two huge Limas step peelers are<br />

used, and each peeler is capable <strong>of</strong> peeling 6 tonnes per hour. They are then<br />

passed through an optical sorter, which removes any potatoes with a set<br />

percentage <strong>of</strong> damage on them, or any signs <strong>of</strong> green. Following the process<br />

down, the potatoes pass over a grading table, if there is any blemishes left on<br />

they are placed on the other side <strong>of</strong> the table to be re-peeled. If ok they either<br />

get diverted to the cutting machine or straight on if the line is set up to produce<br />

whole peeled potatoes. The cutter is capable <strong>of</strong> producing sliced, diced or<br />

chips by varying the slice thickness and inserting a rotating cross cut cylinder.<br />

After the cutter the potatoes are passed through a<br />

cooling auger, a huge refrigerated tank with a<br />

corkscrew to propel the potatoes forward, the<br />

chilled water inside helps reduce the temperature <strong>of</strong><br />

the potato prior to being stored.<br />

The potatoes are then passed through a dipping<br />

auger which contains a solution <strong>of</strong> preservative. This<br />

is constantly measured by the dosing system to<br />

ensure only the correct amount <strong>of</strong> preservative is<br />

used. The chips are then de-slithered using a<br />

vibrating deck with slits that let any fines fall through,<br />

and then sealed in bags.<br />

Nothing is wasted as the peelings are dried and sent<br />

to another company to be used in other products.<br />

The waste water is then pumped to a reed bed<br />

system which filters the water and it is then clean<br />

enough to return to the water table.<br />

Limas Potato peeler<br />

<strong>Issue</strong> 5 <strong>Jul</strong>y <strong>2012</strong><br />

Colin then took us to view some potatoes growing in the fields. The first<br />

samples we looked at were still pretty immature, with small tubers. We moved<br />

to another field where the potatoes were further on and just weeks from<br />

harvest. This kind <strong>of</strong> trip is very useful as the more knowledge you have to<br />

pass on to your customers the better.<br />

Trawler visit<br />

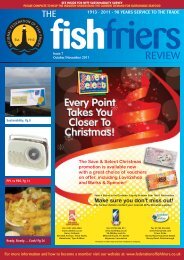

We left FFF and headed in convoy to Fleetwood to visit a Heritage Trawler called<br />

The Jacinta. Now out <strong>of</strong> commission, this trawler fished from Fleetwood and<br />

latterly in Hull before finally hanging up its nets in the mid-1990s. It is now<br />

used as a floating museum to show what life and conditions were like on board<br />

a trawler.<br />

We were shown the entire process <strong>of</strong> fishing, from how the nets worked to<br />

where the fish were stored in the hole. Conditions must have been tough as it<br />

would have been Arctic weather on deck and it was red hot down below.<br />

<strong>Fish</strong>ermen were <strong>of</strong>ten expected to work extremely long shifts when the fishing<br />

was good and lived in reasonably cramped conditions. The guide showed us<br />

some <strong>of</strong> the fish finding and navigational equipment in the wheel hose, before<br />

allowing us all a photo opportunity playing captain at the helm!<br />

At the end <strong>of</strong> the trip we were treated to fish and chips in the meeting room in<br />

the heart <strong>of</strong> the Jacinta. Richardson’s <strong>Fish</strong> Restaurant in Fleetwood kindly<br />

delivered to the vessel! Thanks must go to Sean Lloyd for organising the trip,<br />

all at Fylde, Fresh and Fabulous for the tour <strong>of</strong> the farm, the crew <strong>of</strong> the Jacinta<br />

and also Richardson’s for cracking fish and chips!<br />

Register at Young<strong>Friers</strong>.com for information on future trips!<br />

Aboard the Jacinta<br />

31