MIC Green Book

MIC Green Book

MIC Green Book

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

C H A P T E R T W O<br />

RESPONSE OF METALS<br />

12<br />

TITANIUM<br />

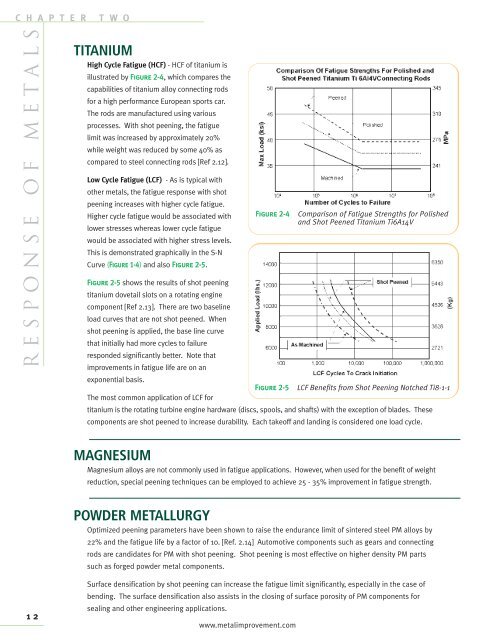

High Cycle Fatigue (HCF) - HCF of titanium is<br />

illustrated by Figure 2-4, which compares the<br />

capabilities of titanium alloy connecting rods<br />

for a high performance European sports car.<br />

The rods are manufactured using various<br />

processes. With shot peening, the fatigue<br />

limit was increased by approximately 20%<br />

while weight was reduced by some 40% as<br />

compared to steel connecting rods [Ref 2.12].<br />

Low Cycle Fatigue (LCF) - As is typical with<br />

other metals, the fatigue response with shot<br />

peening increases with higher cycle fatigue.<br />

Higher cycle fatigue would be associated with<br />

lower stresses whereas lower cycle fatigue<br />

would be associated with higher stress levels.<br />

This is demonstrated graphically in the S-N<br />

Curve (Figure 1-4) and also Figure 2-5.<br />

Figure 2-4 Comparison of Fatigue Strengths for Polished<br />

and Shot Peened Titanium Ti6A14V<br />

Figure 2-5 shows the results of shot peening<br />

titanium dovetail slots on a rotating engine<br />

component [Ref 2.13]. There are two baseline<br />

load curves that are not shot peened. When<br />

shot peening is applied, the base line curve<br />

that initially had more cycles to failure<br />

responded significantly better. Note that<br />

improvements in fatigue life are on an<br />

exponential basis.<br />

Figure 2-5 LCF Benefits from Shot Peening Notched Ti8-1-1<br />

The most common application of LCF for<br />

titanium is the rotating turbine engine hardware (discs, spools, and shafts) with the exception of blades. These<br />

components are shot peened to increase durability. Each takeoff and landing is considered one load cycle.<br />

MAGNESIUM<br />

Magnesium alloys are not commonly used in fatigue applications. However, when used for the benefit of weight<br />

reduction, special peening techniques can be employed to achieve 25 - 35% improvement in fatigue strength.<br />

POWDER METALLURGY<br />

Optimized peening parameters have been shown to raise the endurance limit of sintered steel PM alloys by<br />

22% and the fatigue life by a factor of 10. [Ref. 2.14] Automotive components such as gears and connecting<br />

rods are candidates for PM with shot peening. Shot peening is most effective on higher density PM parts<br />

such as forged powder metal components.<br />

Surface densification by shot peening can increase the fatigue limit significantly, especially in the case of<br />

bending. The surface densification also assists in the closing of surface porosity of PM components for<br />

sealing and other engineering applications.<br />

www.metalimprovement.com