MIC Green Book

MIC Green Book

MIC Green Book

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

FRETTING FAILURE<br />

Fretting occurs when two highly loaded members have a common<br />

surface at which rubbing and sliding take place. Relative<br />

movements of microscopic amplitude result in surface<br />

discoloration, pitting and eventual fatigue. Fine abrasive oxides<br />

develop that further contribute to scoring of the surfaces. Other<br />

failure mechanisms, such as fretting corrosion and fretting wear,<br />

commonly accompany fretting failures.<br />

Shot peening has been used to prevent fretting and eventual<br />

fretting failures by texturing the surface with a non-directional<br />

finish. This results in surface hardening (of certain materials) and<br />

a layer of compressive stress. The compressive layer prevents<br />

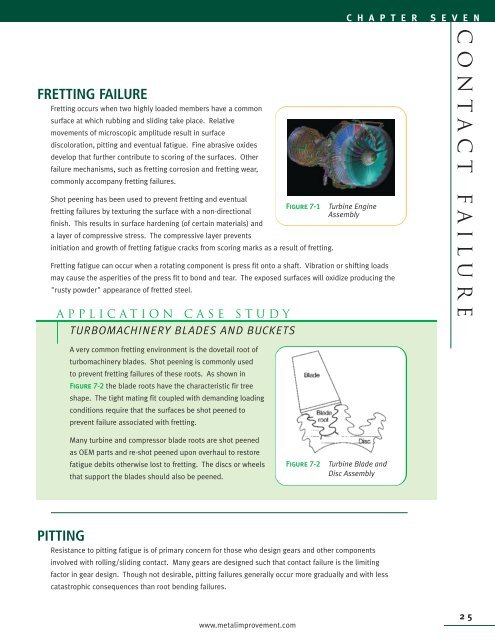

Figure 7-1 Turbine Engine<br />

Assembly<br />

initiation and growth of fretting fatigue cracks from scoring marks as a result of fretting.<br />

Fretting fatigue can occur when a rotating component is press fit onto a shaft. Vibration or shifting loads<br />

may cause the asperities of the press fit to bond and tear. The exposed surfaces will oxidize producing the<br />

"rusty powder" appearance of fretted steel.<br />

Application Case Study<br />

TURBOMACHINERY BLADES AND BUCKETS<br />

A very common fretting environment is the dovetail root of<br />

turbomachinery blades. Shot peening is commonly used<br />

to prevent fretting failures of these roots. As shown in<br />

Figure 7-2 the blade roots have the characteristic fir tree<br />

shape. The tight mating fit coupled with demanding loading<br />

conditions require that the surfaces be shot peened to<br />

prevent failure associated with fretting.<br />

Many turbine and compressor blade roots are shot peened<br />

as OEM parts and re-shot peened upon overhaul to restore<br />

fatigue debits otherwise lost to fretting. The discs or wheels<br />

that support the blades should also be peened.<br />

PITTING<br />

Resistance to pitting fatigue is of primary concern for those who design gears and other components<br />

involved with rolling/sliding contact. Many gears are designed such that contact failure is the limiting<br />

factor in gear design. Though not desirable, pitting failures generally occur more gradually and with less<br />

catastrophic consequences than root bending failures.<br />

www.metalimprovement.com<br />

Figure 7-2 Turbine Blade and<br />

Disc Assembly<br />

C H A P T E R S E V E N<br />

C O NTACT FAILURE<br />

25