MIC Green Book

MIC Green Book

MIC Green Book

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

SPECIFYING SHOT PEENING<br />

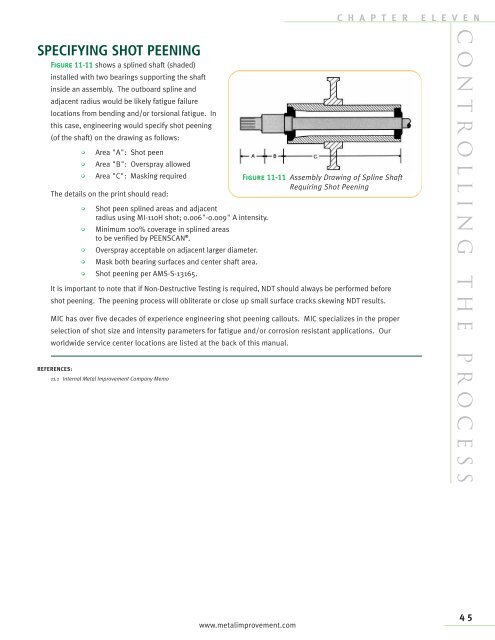

Figure 11-11 shows a splined shaft (shaded)<br />

installed with two bearings supporting the shaft<br />

inside an assembly. The outboard spline and<br />

adjacent radius would be likely fatigue failure<br />

locations from bending and/or torsional fatigue. In<br />

this case, engineering would specify shot peening<br />

(of the shaft) on the drawing as follows:<br />

• Area "A": Shot peen<br />

• Area "B": Overspray allowed<br />

• Area "C": Masking required<br />

The details on the print should read:<br />

• Shot peen splined areas and adjacent<br />

radius using MI-110H shot; 0.006"-0.009" A intensity.<br />

• Minimum 100% coverage in splined areas<br />

to be verified by PEENSCAN ® .<br />

• Overspray acceptable on adjacent larger diameter.<br />

• Mask both bearing surfaces and center shaft area.<br />

• Shot peening per AMS-S-13165.<br />

It is important to note that if Non-Destructive Testing is required, NDT should always be performed before<br />

shot peening. The peening process will obliterate or close up small surface cracks skewing NDT results.<br />

<strong>MIC</strong> has over five decades of experience engineering shot peening callouts. <strong>MIC</strong> specializes in the proper<br />

selection of shot size and intensity parameters for fatigue and/or corrosion resistant applications. Our<br />

worldwide service center locations are listed at the back of this manual.<br />

REFERENCES:<br />

11.1 Internal Metal Improvement Company Memo<br />

Figure 11-11 Assembly Drawing of Spline Shaft<br />

Requiring Shot Peening<br />

www.metalimprovement.com<br />

C H A P T E R E L E V E N<br />

C O NTRO LLING THE PROCESS<br />

45