MIC Green Book

MIC Green Book

MIC Green Book

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

C H A P T E R T W O<br />

RESPONSE OF METALS<br />

8<br />

HIGH STRENGTH STEELS<br />

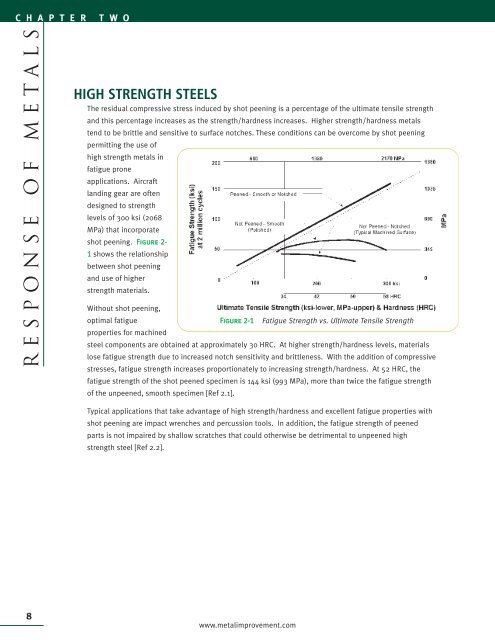

The residual compressive stress induced by shot peening is a percentage of the ultimate tensile strength<br />

and this percentage increases as the strength/hardness increases. Higher strength/hardness metals<br />

tend to be brittle and sensitive to surface notches. These conditions can be overcome by shot peening<br />

permitting the use of<br />

high strength metals in<br />

fatigue prone<br />

applications. Aircraft<br />

landing gear are often<br />

designed to strength<br />

levels of 300 ksi (2068<br />

MPa) that incorporate<br />

shot peening. Figure 2-<br />

1 shows the relationship<br />

between shot peening<br />

and use of higher<br />

strength materials.<br />

Without shot peening,<br />

optimal fatigue<br />

Figure 2-1 Fatigue Strength vs. Ultimate Tensile Strength<br />

properties for machined<br />

steel components are obtained at approximately 30 HRC. At higher strength/hardness levels, materials<br />

lose fatigue strength due to increased notch sensitivity and brittleness. With the addition of compressive<br />

stresses, fatigue strength increases proportionately to increasing strength/hardness. At 52 HRC, the<br />

fatigue strength of the shot peened specimen is 144 ksi (993 MPa), more than twice the fatigue strength<br />

of the unpeened, smooth specimen [Ref 2.1].<br />

Typical applications that take advantage of high strength/hardness and excellent fatigue properties with<br />

shot peening are impact wrenches and percussion tools. In addition, the fatigue strength of peened<br />

parts is not impaired by shallow scratches that could otherwise be detrimental to unpeened high<br />

strength steel [Ref 2.2].<br />

www.metalimprovement.com