MIC Green Book

MIC Green Book

MIC Green Book

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

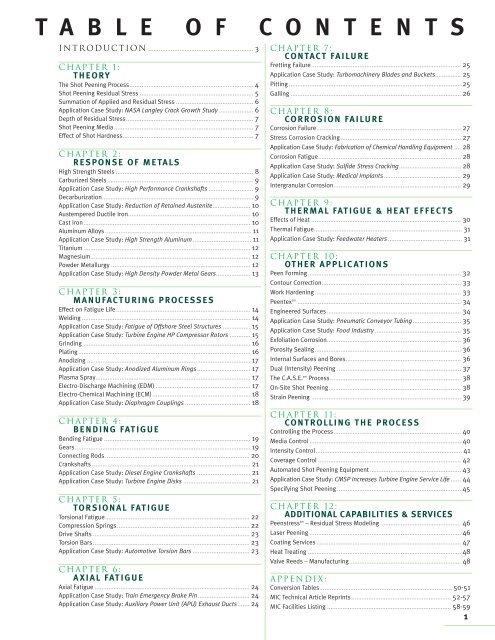

T A B L E O F C O N T E N T S<br />

INTRODUCTION ............................................................. 3<br />

CHAPTER 1:<br />

THEORY<br />

The Shot Peening Process........................................................................ 4<br />

Shot Peening Residual Stress .................................................................. 5<br />

Summation of Applied and Residual Stress ............................................. 6<br />

Application Case Study: NASA Langley Crack Growth Study .................... 6<br />

Depth of Residual Stress.......................................................................... 7<br />

Shot Peening Media ................................................................................. 7<br />

Effect of Shot Hardness............................................................................ 7<br />

CHAPTER 2:<br />

RESPONSE OF METALS<br />

High Strength Steels ................................................................................ 8<br />

Carburized Steels ..................................................................................... 9<br />

Application Case Study: High Performance Crankshafts .......................... 9<br />

Decarburization........................................................................................ 9<br />

Application Case Study: Reduction of Retained Austenite...................... 10<br />

Austempered Ductile Iron....................................................................... 10<br />

Cast Iron................................................................................................. 10<br />

Aluminum Alloys ..................................................................................... 11<br />

Application Case Study: High Strength Aluminum .................................. 11<br />

Titanium ................................................................................................. 12<br />

Magnesium............................................................................................. 12<br />

Powder Metallurgy ................................................................................. 12<br />

Application Case Study: High Density Powder Metal Gears.................... 13<br />

CHAPTER 3:<br />

MANUFACTURING PROCESSES<br />

Effect on Fatigue Life .............................................................................. 14<br />

Welding .................................................................................................. 14<br />

Application Case Study: Fatigue of Offshore Steel Structures ................ 15<br />

Application Case Study: Turbine Engine HP Compressor Rotors ............ 15<br />

Grinding ................................................................................................. 16<br />

Plating .................................................................................................... 16<br />

Anodizing ............................................................................................... 17<br />

Application Case Study: Anodized Aluminum Rings............................... 17<br />

Plasma Spray.......................................................................................... 17<br />

Electro-Discharge Machining (EDM) ....................................................... 17<br />

Electro-Chemical Machining (ECM)......................................................... 18<br />

Application Case Study: Diaphragm Couplings ...................................... 18<br />

CHAPTER 4:<br />

BENDING FATIGUE<br />

Bending Fatigue ..................................................................................... 19<br />

Gears...................................................................................................... 19<br />

Connecting Rods.................................................................................... 20<br />

Crankshafts ............................................................................................ 21<br />

Application Case Study: Diesel Engine Crankshafts ............................... 21<br />

Application Case Study: Turbine Engine Disks ....................................... 21<br />

CHAPTER 5:<br />

TORSIONAL FATIGUE<br />

Torsional Fatigue.................................................................................... 22<br />

Compression Springs............................................................................. 22<br />

Drive Shafts ........................................................................................... 23<br />

Torsion Bars........................................................................................... 23<br />

Application Case Study: Automotive Torsion Bars ................................. 23<br />

CHAPTER 6:<br />

AXIAL FATIGUE<br />

Axial Fatigue .......................................................................................... 24<br />

Application Case Study: Train Emergency Brake Pin.............................. 24<br />

Application Case Study: Auxiliary Power Unit (APU) Exhaust Ducts....... 24<br />

CHAPTER 7:<br />

CONTACT FAILURE<br />

Fretting Failure....................................................................................... 25<br />

Application Case Study: Turbomachinery Blades and Buckets............... 25<br />

Pitting .....................................................................................................25<br />

Galling ................................................................................................... 26<br />

CHAPTER 8:<br />

CORROSION FAILURE<br />

Corrosion Failure.................................................................................... 27<br />

Stress Corrosion Cracking...................................................................... 27<br />

Application Case Study: Fabrication of Chemical Handling Equipment .... 28<br />

Corrosion Fatigue................................................................................... 28<br />

Application Case Study: Sulfide Stress Cracking.................................... 28<br />

Application Case Study: Medical Implants............................................. 29<br />

Intergranular Corrosion.......................................................................... 29<br />

CHAPTER 9:<br />

THERMAL FATIGUE & HEAT EFFECTS<br />

Effects of Heat ....................................................................................... 30<br />

Thermal Fatigue...................................................................................... 31<br />

Application Case Study: Feedwater Heaters ........................................... 31<br />

CHAPTER 10:<br />

OTHER APPLICATIONS<br />

Peen Forming ......................................................................................... 32<br />

Contour Correction................................................................................. 33<br />

Work Hardening ..................................................................................... 33<br />

Peentex sm ............................................................................................... 34<br />

Engineered Surfaces .............................................................................. 34<br />

Application Case Study: Pneumatic Conveyor Tubing............................ 35<br />

Application Case Study: Food Industry .................................................. 35<br />

Exfoliation Corrosion.............................................................................. 36<br />

Porosity Sealing..................................................................................... 36<br />

Internal Surfaces and Bores................................................................... 36<br />

Dual (Intensity) Peening ........................................................................ 37<br />

The C.A.S.E. sm Process ............................................................................ 38<br />

On-Site Shot Peening............................................................................. 38<br />

Strain Peening ....................................................................................... 39<br />

CHAPTER 11:<br />

CONTROLLING THE PROCESS<br />

Controlling the Process.......................................................................... 40<br />

Media Control ........................................................................................ 40<br />

Intensity Control..................................................................................... 41<br />

Coverage Control ................................................................................... 42<br />

Automated Shot Peening Equipment ..................................................... 43<br />

Application Case Study: CMSP Increases Turbine Engine Service Life ...... 44<br />

Specifying Shot Peening ........................................................................ 45<br />

CHAPTER 12:<br />

ADDITIONAL CAPABILITIES & SERVICES<br />

Peenstress sm – Residual Stress Modeling ............................................... 46<br />

Laser Peening ........................................................................................ 46<br />

Coating Services .................................................................................... 47<br />

Heat Treating ......................................................................................... 48<br />

Valve Reeds – Manufacturing................................................................. 48<br />

APPENDIX:<br />

Conversion Tables............................................................................. 50-51<br />

<strong>MIC</strong> Technical Article Reprints.......................................................... 52-57<br />

<strong>MIC</strong> Facilities Listing ........................................................................ 58-59<br />

1