PDF - 3756 kB - CARNet

PDF - 3756 kB - CARNet

PDF - 3756 kB - CARNet

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

O. HÍRE[ et al.: MECHANICAL PROPERTIES OF FORGINGS DEPENDING ON THE CHANGES IN SHAPE...<br />

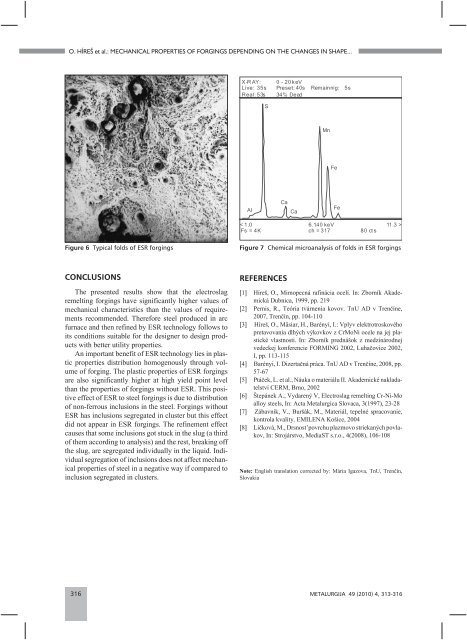

Figure 6 Typical folds of ESR forgings Figure 7 Chemical microanalysis of folds in ESR forgings<br />

CONCLUSIONS<br />

The presented results show that the electroslag<br />

remelting forgings have significantly higher values of<br />

mechanical characteristics than the values of requirements<br />

recommended. Therefore steel produced in arc<br />

furnace and then refined by ESR technology follows to<br />

its conditions suitable for the designer to design products<br />

with better utility properties.<br />

An important benefit of ESR technology lies in plastic<br />

properties distribution homogenously through volume<br />

of forging. The plastic properties of ESR forgings<br />

are also significantly higher at high yield point level<br />

than the properties of forgings without ESR. This positive<br />

effect of ESR to steel forgings is due to distribution<br />

of non-ferrous inclusions in the steel. Forgings without<br />

ESR has inclusions segregated in cluster but this effect<br />

did not appear in ESR forgings. The refinement effect<br />

causes that some inclusions got stuck in the slug (a third<br />

of them according to analysis) and the rest, breaking off<br />

the slug, are segregated individually in the liquid. Individual<br />

segregation of inclusions does not affect mechanical<br />

properties of steel in a negative way if compared to<br />

inclusion segregated in clusters.<br />

REFERENCES<br />

1 Híre{, O., Mimopecná rafinácia ocelí. In: Zborník Akademická<br />

Dubnica, 1999, pp. 219<br />

2 Pernis, R., Teória tvárnenia kovov. TnU AD v Tren~íne,<br />

2007, Tren~ín, pp. 104-110<br />

3 Híre{, O., Mäsiar, H., Barényi, I.: Vplyv elektrotroskového<br />

pretavovania dlhých výkovkov z CrMoNi ocele na jej plastické<br />

vlastnosti. In: Zborník predná{ok z medzinárodnej<br />

vedeckej konferencie FORMING 2002, Luha~ovice 2002,<br />

I, pp. 113-115<br />

4 Barényi, I. Dizerta~ná práca. TnU AD v Tren~íne, 2008, pp.<br />

57-67<br />

5 Ptá~ek, L. et al., Náuka o materiálu II. Akademické nakladatelství<br />

CERM, Brno, 2002<br />

6 [tepánek A., Vydarený V, Electroslag remelting Cr-Ni-Mo<br />

alloy steels, In: Acta Metalurgica Slovaca, 3(1997), 23-28<br />

7 Zábavník, V., Bur{ák, M., Materiál, tepelné spracovanie,<br />

kontrola kvality. EMILENA Ko{ice, 2004<br />

8 Li~ková, M., Drsnost’povrchu plazmovo striekaných povlakov,<br />

In: Strojárstvo, MediaST s.r.o., 4(2008), 106-108<br />

Note: English translation corrected by: Mária Igazova, TnU, Tren~ín,<br />

Slovakia<br />

316 METALURGIJA 49 (2010) 4, 313-316