PDF - 3756 kB - CARNet

PDF - 3756 kB - CARNet

PDF - 3756 kB - CARNet

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

M. BUR[ÁK et al.: INFLUENCE OF THE STRAIN RATE ON THE MECHANICAL AND TECHNOLOGICAL PROPERTIES...<br />

For static tensile tests a universal test machine<br />

INSTRON 1185 was used and this machine was used retooled<br />

with an Erichsen test fixture for the deep-drawing<br />

tests in the press tool velocity interval from 3,3·10 –3<br />

m·s –1 to 1,10 –1 m·s –1 . Deep-drawing tests with speed<br />

punch up to 2,5 m·s –1 were done by drop tower.<br />

EXPERIMENTAL RESULTS AND DISCUSSION<br />

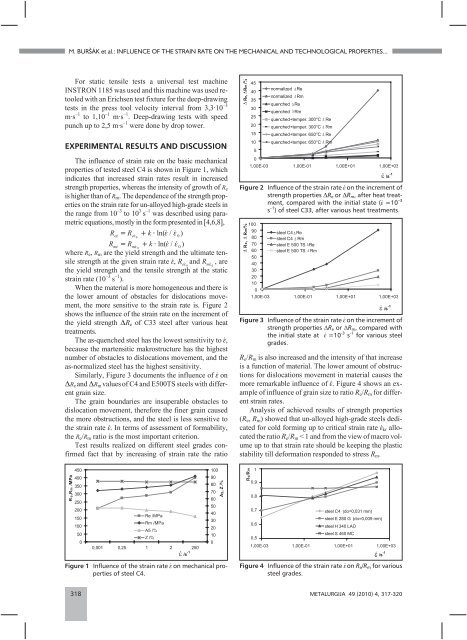

The influence of strain rate on the basic mechanical<br />

properties of tested steel C4 is shown in Figure 1, which<br />

indicates that increased strain rates result in increased<br />

strength properties, whereas the intensity of growth of Re<br />

is higher than of Rm. The dependence of the strength properties<br />

on the strain rate for un-alloyed high-grade steels in<br />

the range from 10 –3 to 10 3 s –1 was described using parametric<br />

equations, mostly in the form presented in 4,6,8,<br />

Re Re k ln( / )<br />

0<br />

0<br />

Rm Rm k ln( / )<br />

0<br />

0<br />

where Re, Rm are the yield strength and the ultimate tensile<br />

strength at the given strain rate , R and R , are<br />

e0 m0<br />

the yield strength and the tensile strength at the static<br />

strain rate (10 –3 s –1 ).<br />

When the material is more homogeneous and there is<br />

the lower amount of obstacles for dislocations movement,<br />

the more sensitive to the strain rate is. Figure 2<br />

shows the influence of the strain rate on the increment of<br />

the yield strength Re of C33 steel after various heat<br />

treatments.<br />

The as-quenched steel has the lowest sensitivity to ,<br />

because the martensitic makrostructure has the highest<br />

number of obstacles to dislocations movement, and the<br />

as-normalized steel has the highest sensitivity.<br />

Similarly, Figure 3 documents the influence of on<br />

Reand Rmvaluesof C4 and E500TS steels with different<br />

grain size.<br />

The grain boundaries are insuperable obstacles to<br />

dislocation movement, therefore the finer grain caused<br />

the more obstructions, and the steel is less sensitive to<br />

the strain rate . In terms of assessment of formability,<br />

the Re/Rm ratio is the most important criterion.<br />

Test results realized on different steel grades confirmed<br />

fact that by increasing of strain rate the ratio<br />

Figure 1 Influence of the strain rate on mechanical properties<br />

of steel C4.<br />

Figure 2 Influence of the strain rate on the increment of<br />

strength properties Re or Rm, after heat treatment,<br />

compared with the initial state ( =10 –3<br />

s –1 ) of steel C33, after various heat treatments.<br />

Figure 3 Influence of the strain rate on the increment of<br />

strength properties ÄRe or ÄRm, compared with<br />

the initial state at =10 -3 s -1 for various steel<br />

grades.<br />

Re/Rm is also increased and the intensity of that increase<br />

is a function of material. The lower amount of obstructions<br />

for dislocations movement in material causes the<br />

more remarkable influence of . Figure 4 shows an example<br />

of influence of grain size to ratio Re/Rm for different<br />

strain rates.<br />

Analysis of achieved results of strength properties<br />

(Re, Rm) showed that un-alloyed high-grade steels dedicated<br />

for cold forming up to critical strain rate kr allocated<br />

the ratio Re/Rm < 1 and from the view of macro volume<br />

up to that strain rate should be keeping the plastic<br />

stability till deformation responded to stress Rm.<br />

Figure 4 Influence of the strain rate on Re/Rm for various<br />

steel grades.<br />

318 METALURGIJA 49 (2010) 4, 317-320