Download - Evonik Industries

Download - Evonik Industries

Download - Evonik Industries

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

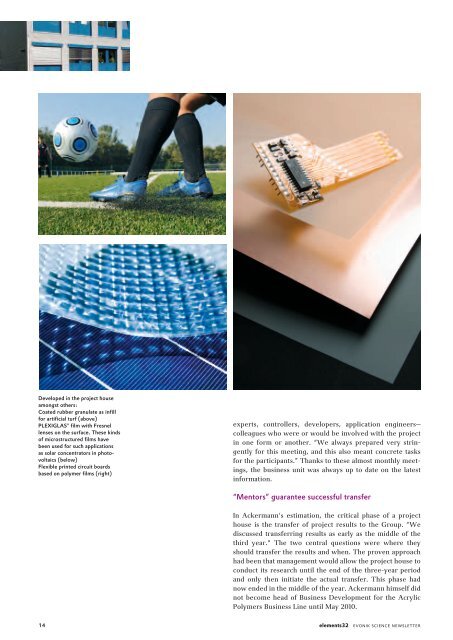

Developed in the project house<br />

amongst others:<br />

Coated rubber granu late as infill<br />

for artificial turf (above)<br />

PLEXIGLAS® film with Fresnel<br />

lenses on the surface. These kinds<br />

of microstructured films have<br />

been used for such applications<br />

as solar concentrators in photo -<br />

voltaics (below)<br />

Flexible printed circuit boards<br />

based on polymer films (right)<br />

experts, controllers, developers, application engineers—<br />

colleagues who were or would be involved with the project<br />

in one form or another. “We always prepared very stringently<br />

for this meeting, and this also meant concrete tasks<br />

for the participants.” Thanks to these almost monthly meetings,<br />

the business unit was always up to date on the latest<br />

informa tion.<br />

“Mentors” guarantee successful transfer<br />

In Ackermann‘s estimation, the critical phase of a project<br />

house is the transfer of project results to the Group. “We<br />

discussed transferring results as early as the middle of the<br />

third year.“ The two central questions were where they<br />

should transfer the results and when. The proven approach<br />

had been that management would allow the project house to<br />

conduct its research until the end of the three-year period<br />

and only then initiate the actual transfer. This phase had<br />

now ended in the middle of the year. Ackermann himself did<br />

not become head of Business Development for the Acrylic<br />

Polymers Business Line until May 2010.<br />

14 elements32 evonik science newsletter