Download - Evonik Industries

Download - Evonik Industries

Download - Evonik Industries

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

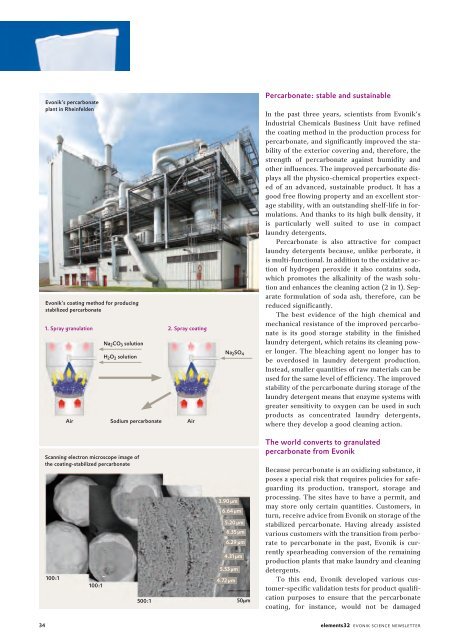

<strong>Evonik</strong>’s percarbonate<br />

plant in Rheinfelden<br />

<strong>Evonik</strong>’s coating method for producing<br />

stabilized percarbonate<br />

1. Spray granulation 2. Spray coating<br />

Scanning electron microscope image of<br />

the coating-stabilized percarbonate<br />

100:1<br />

Na 2CO 3 solution<br />

H 2O 2 solution<br />

Air Sodium percarbonate Air<br />

100:1<br />

Na 2SO 4<br />

3.90 µm<br />

6.64 µm<br />

5.20 µm<br />

6.35 µm<br />

6.29 µm<br />

4.31 µm<br />

5.53 µm<br />

4.72 µm<br />

500:1 50µm<br />

Percarbonate: stable and sustainable<br />

In the past three years, scientists from <strong>Evonik</strong>‘s<br />

Industrial Chemicals Business Unit have refined<br />

the coating method in the production process for<br />

percarbonate, and significantly improved the stability<br />

of the exterior covering and, therefore, the<br />

strength of percarbonate against humidity and<br />

other influences. The improved percarbonate displays<br />

all the physico-chemical properties expected<br />

of an advanced, sustainable product. It has a<br />

good free flowing property and an excellent storage<br />

stability, with an outstanding shelf-life in formulations.<br />

And thanks to its high bulk density, it<br />

is particularly well suited to use in compact<br />

laundry detergents.<br />

Percarbonate is also attractive for compact<br />

laundry detergents because, unlike perborate, it<br />

is multi-functional. In addition to the oxidative action<br />

of hydrogen peroxide it also contains soda,<br />

which promotes the alkalinity of the wash solution<br />

and enhances the cleaning action (2 in 1). Se p -<br />

arate formulation of soda ash, therefore, can be<br />

reduced significantly.<br />

The best evidence of the high chemical and<br />

mechanical resistance of the improved percarbonate<br />

is its good storage stability in the finished<br />

laundry detergent, which retains its cleaning power<br />

longer. The bleaching agent no longer has to<br />

be overdosed in laundry detergent production.<br />

Instead, smaller quantities of raw materials can be<br />

used for the same level of efficiency. The improved<br />

stability of the percarbonate during storage of the<br />

laundry detergent means that enzyme systems with<br />

greater sensitivity to oxygen can be used in such<br />

products as concentrated laundry detergents,<br />

where they develop a good cleaning action.<br />

The world converts to granulated<br />

percarbonate from <strong>Evonik</strong><br />

Because percarbonate is an oxidizing substance, it<br />

poses a special risk that requires policies for safeguarding<br />

its production, transport, storage and<br />

processing. The sites have to have a permit, and<br />

may store only certain quantities. Customers, in<br />

turn, receive advice from <strong>Evonik</strong> on storage of the<br />

stabilized percarbonate. Having already assisted<br />

various customers with the transition from perborate<br />

to percarbonate in the past, <strong>Evonik</strong> is currently<br />

spearheading conversion of the remaining<br />

production plants that make laundry and cleaning<br />

detergents.<br />

To this end, <strong>Evonik</strong> developed various cus -<br />

t omer-specific validation tests for product qualification<br />

purposes to ensure that the percarbonate<br />

coating, for instance, would not be damaged<br />

34 elements32 evonik science newsletter