Download - Evonik Industries

Download - Evonik Industries

Download - Evonik Industries

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

ficantly smaller piece counts, they are produced in a<br />

heat forming process. By the end of their first development<br />

year, they had already received approval from<br />

the German Federal Motor Transport Authority that<br />

covers not only roof glazing but also rear and fixed<br />

side windows. This meant that concrete projects with<br />

customers could be started as early as the second year<br />

of the project house. Various automobile manufacturers<br />

are currently conducting street tests of the<br />

first PLEXIGLAS® glazing in prototype vehicles.<br />

In another project, the developers investigated<br />

how a photovoltaic function might be integrated into<br />

the roof glazing. The challenge for developers of<br />

these power-supplying variants is that the PV cell and<br />

polymer composite show different thermal expansion<br />

coefficients. To ensure that the solar cells do not tear,<br />

the researchers developed a sandwich structure, in<br />

which the optically active cells are embedded in an<br />

elastomer matrix that is decoupled from the exterior<br />

PLEXIGLAS® composite layers. They have developed<br />

three different processing techniques in all for manufacturing<br />

such composites.<br />

These composites, however, are flat PV semi-<br />

finished products that still have to be formed into the<br />

spherical shape of the roof glazing. The developers<br />

have successfully advanced these to prototype status:<br />

To make them operational, they produced prototypical<br />

roofs for a standard subcompact car, including<br />

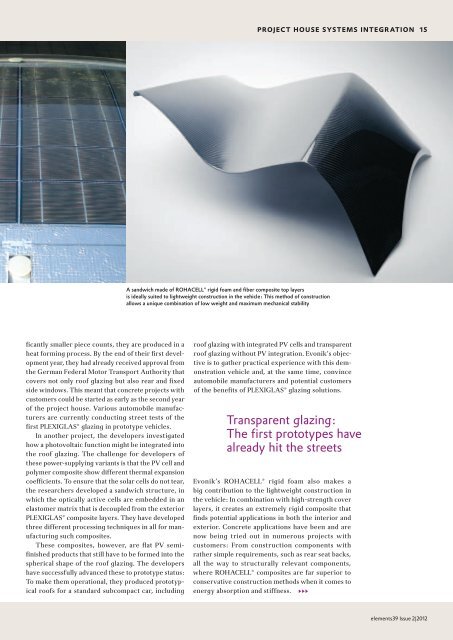

A sandwich made of rOHACeLL® rigid foam and fiber composite top layers<br />

is ideally suited to lightweight construction in the vehicle: this method of construction<br />

allows a unique combination of low weight and maximum mechanical stability<br />

PRoJeCt HoUse sYsteMs InteGRAtIon<br />

roof glazing with integrated PV cells and transparent<br />

roof glazing without PV integration. <strong>Evonik</strong>’s objective<br />

is to gather practical experience with this demonstration<br />

vehicle and, at the same time, convince<br />

automobile manufacturers and potential customers<br />

of the benefits of PLEXIGLAS® glazing solutions.<br />

Transparent glazing:<br />

The first prototypes have<br />

already hit the streets<br />

<strong>Evonik</strong>’s ROHACELL® rigid foam also makes a<br />

big contribution to the lightweight construction in<br />

the vehicle: In combination with high-strength cover<br />

layers, it creates an extremely rigid composite that<br />

finds potential applications in both the interior and<br />

exterior. Concrete applications have been and are<br />

now being tried out in numerous projects with<br />

customers: From construction components with<br />

rather simple requirements, such as rear seat backs,<br />

all the way to structurally relevant components,<br />

where ROHACELL® composites are far superior to<br />

conservative construction methods when it comes to<br />

energy absorption and stiffness.<br />

333<br />

15<br />

elements39 Issue 2|2012