Download - Evonik Industries

Download - Evonik Industries

Download - Evonik Industries

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Patients Who suffeR from stomach or intestinal<br />

tumors can experience constriction of the digestive<br />

tract—a condition called stenosis, which prevents food<br />

from passing through. In these cases, a stent—an elastic,<br />

tube-shaped, self-expanding wire mesh that<br />

unfolds following placement in the esophagus or the<br />

affected section of the intestine—reopens the pathway<br />

for food. The stent does not cure the patient’s<br />

disease, but it does alleviate suffering and improves<br />

the patient’s quality of life.<br />

Traditionally produced from polyamide or polyester,<br />

stents can now be made from <strong>Evonik</strong>’s polyetheretherketone<br />

(PEEK) VESTAKEEP® as well. The<br />

material boasts not only excellent biocompatibility,<br />

which <strong>Evonik</strong> has verified in numerous tests by<br />

external testing institutes, but also high biostability.<br />

The latter is a direct result of the aromatic, partially<br />

crystalline properties of the PEEK polymer, which<br />

not only imparts outstanding resistance to corrosion,<br />

hydrolysis, and chemicals but also renders it inert to<br />

bodily liquids—the material retains its stability, even<br />

under aggressive conditions.<br />

The stents are one of the new medical applications<br />

<strong>Evonik</strong> has opened up with VESTAKEEP®. The fact<br />

that EPT—<strong>Evonik</strong> Polymer Technology GmbH, which<br />

manufactures PEEK semi-finished products—is certi-<br />

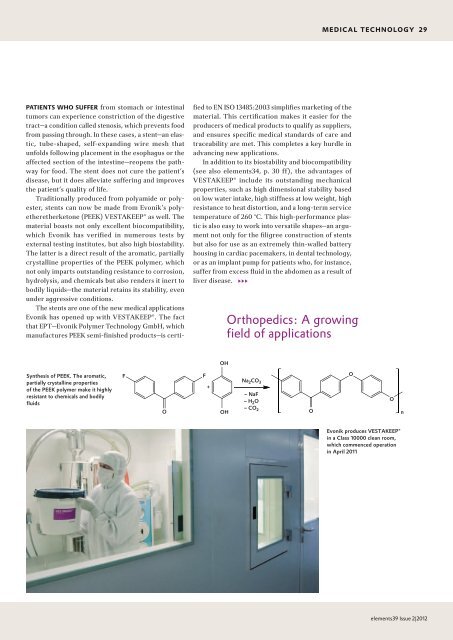

Synthesis of PeeK. the aromatic,<br />

partially crystalline properties<br />

of the PeeK polymer make it highly<br />

resistant to chemicals and bodily<br />

fluids<br />

fied to EN ISO 13485:2003 simplifies marketing of the<br />

material. This certification makes it easier for the<br />

producers of medical products to qualify as suppliers,<br />

and ensures specific medical standards of care and<br />

traceability are met. This completes a key hurdle in<br />

advancing new applications.<br />

In addition to its biostability and biocompatibility<br />

(see also elements34, p. 30 ff), the advantages of<br />

VESTAKEEP® include its outstanding mechanical<br />

properties, such as high dimensional stability based<br />

on low water intake, high stiffness at low weight, high<br />

resistance to heat distortion, and a long-term service<br />

temperature of 260 °C. This high-performance plastic<br />

is also easy to work into versatile shapes—an argument<br />

not only for the filigree construction of stents<br />

but also for use as an extremely thin-walled battery<br />

housing in cardiac pacemakers, in dental technology,<br />

or as an implant pump for patients who, for instance,<br />

suffer from excess fluid in the abdomen as a result of<br />

liver disease. 333<br />

Orthopedics: A growing<br />

field of applications<br />

F F<br />

+<br />

na2CO3 – naF<br />

– H2O O OH<br />

– CO2 O<br />

OH<br />

MedICAL teCHnoLoGY<br />

O<br />

O<br />

evonik produces veStAKeeP®<br />

in a Class 10000 clean room,<br />

which commenced operation<br />

in April 2011<br />

n<br />

29<br />

elements39 Issue 2|2012