Download - Evonik Industries

Download - Evonik Industries

Download - Evonik Industries

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

it Remains a challenge for catalysis experts to completely<br />

characterize a solid catalyst. Due to the complexity<br />

of these catalysts, they do not form a uniform<br />

phase, but display various polymorphic solid phases<br />

at once, which are also not defined at the molecular<br />

level. As a result, many physical and chemical properties<br />

are subject to broad distribution. Good examples<br />

include the particle sizes of the carrier materials,<br />

the size of the metal particles on the carriers, the<br />

acidity or basicity of surface centers, or even the oxidation<br />

conditions of the active transition metal components.<br />

It becomes even more complicated when the conditions<br />

on the edges of the distribution functions influence<br />

the catalytic properties. With their content<br />

being so infinitesimally small, it is difficult or impossible<br />

to use physicochemical methods to identify and<br />

quantify them.<br />

As a catalyst producer, however, <strong>Evonik</strong> must ensure<br />

the consistent quality and performance of its<br />

products. In addition to the standard methods of physicochemical<br />

characterization, such as determining<br />

particle sizes, elementary analysis, determining pore<br />

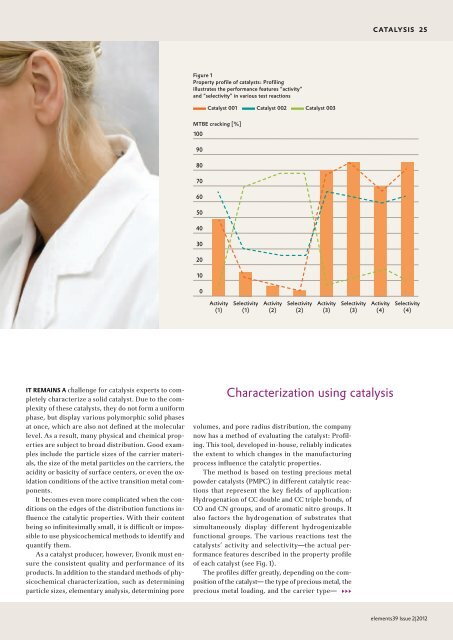

Figure 1<br />

Property profile of catalysts: Profiling<br />

illustrates the performance features “activity”<br />

and “selectivity” in various test reactions<br />

100<br />

90<br />

80<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

Catalyst 001 Catalyst 002 Catalyst 003<br />

MtBe cracking [%]<br />

0<br />

Activity<br />

(1)<br />

Selectivity<br />

(1)<br />

Activity<br />

(2)<br />

Selectivity<br />

(2)<br />

Activity<br />

(3)<br />

Selectivity<br />

(3)<br />

Characterization using catalysis<br />

volumes, and pore radius distribution, the company<br />

now has a method of evaluating the catalyst: Profiling.<br />

This tool, developed in-house, reliably indicates<br />

the extent to which changes in the manufacturing<br />

process influence the catalytic properties.<br />

The method is based on testing precious metal<br />

powder catalysts (PMPC) in different catalytic reactions<br />

that represent the key fields of application:<br />

Hydrogenation of CC double and CC triple bonds, of<br />

CO and CN groups, and of aromatic nitro groups. It<br />

also factors the hydrogenation of substrates that<br />

simultaneously display different hydrogenizable<br />

functional groups. The various reactions test the<br />

catalysts’ activity and selectivity—the actual performance<br />

features described in the property profile<br />

of each catalyst (see Fig. 1).<br />

The profiles differ greatly, depending on the composition<br />

of the catalyst— the type of precious metal, the<br />

precious metal loading, and the carrier type— 333<br />

CAtALYsIs<br />

Activity<br />

(4)<br />

Selectivity<br />

(4)<br />

25<br />

elements39 Issue 2|2012