Download - Evonik Industries

Download - Evonik Industries

Download - Evonik Industries

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

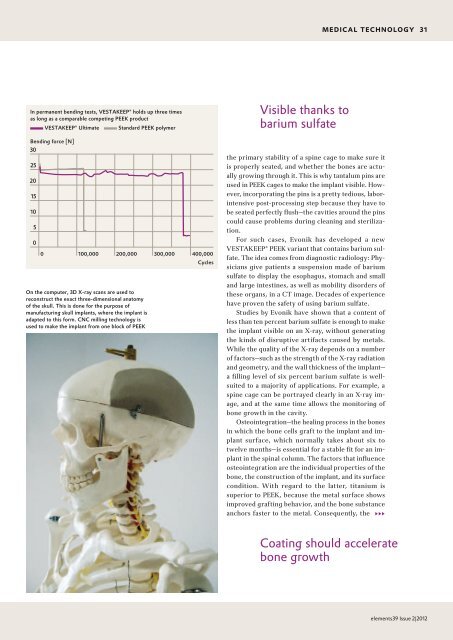

In permanent bending tests, veStAKeeP® holds up three times<br />

as long as a comparable competing PeeK product<br />

veStAKeeP® Ultimate Standard PeeK polymer<br />

Bending force [n]<br />

30<br />

25<br />

20<br />

15<br />

10<br />

5<br />

0<br />

0 100,000 200,000 300,000 400,000<br />

Cycles<br />

On the computer, 3D X-ray scans are used to<br />

reconstruct the exact three-dimensional anatomy<br />

of the skull. this is done for the purpose of<br />

manufacturing skull implants, where the implant is<br />

adapted to this form. CnC milling technology is<br />

used to make the implant from one block of PeeK<br />

Visible thanks to<br />

barium sulfate<br />

MedICAL teCHnoLoGY<br />

the primary stability of a spine cage to make sure it<br />

is properly seated, and whether the bones are actually<br />

growing through it. This is why tantalum pins are<br />

used in PEEK cages to make the implant visible. However,<br />

incorporating the pins is a pretty tedious, laborintensive<br />

post-processing step because they have to<br />

be seated perfectly flush—the cavities around the pins<br />

could cause problems during cleaning and sterilization.<br />

For such cases, <strong>Evonik</strong> has developed a new<br />

VESTAKEEP® PEEK variant that contains barium sulfate.<br />

The idea comes from diagnostic radiology: Physicians<br />

give patients a suspension made of barium<br />

sulfate to display the esophagus, stomach and small<br />

and large intestines, as well as mobility disorders of<br />

these organs, in a CT image. Decades of experience<br />

have proven the safety of using barium sulfate.<br />

Studies by <strong>Evonik</strong> have shown that a content of<br />

less than ten percent barium sulfate is enough to make<br />

the implant visible on an X-ray, without generating<br />

the kinds of disruptive artifacts caused by metals.<br />

While the quality of the X-ray depends on a number<br />

of factors—such as the strength of the X-ray radiation<br />

and geometry, and the wall thickness of the implant—<br />

a filling level of six percent barium sulfate is wellsuited<br />

to a majority of applications. For example, a<br />

spine cage can be portrayed clearly in an X-ray image,<br />

and at the same time allows the monitoring of<br />

bone growth in the cavity.<br />

Osteointegration—the healing process in the bones<br />

in which the bone cells graft to the implant and implant<br />

surface, which normally takes about six to<br />

twelve months—is essential for a stable fit for an implant<br />

in the spinal column. The factors that influence<br />

osteointegration are the individual properties of the<br />

bone, the construction of the implant, and its surface<br />

condition. With regard to the latter, titanium is<br />

superior to PEEK, because the metal surface shows<br />

improved grafting behavior, and the bone substance<br />

anchors faster to the metal. Consequently, the 333<br />

Coating should accelerate<br />

bone growth<br />

31<br />

elements39 Issue 2|2012