October - Library - Central Queensland University

October - Library - Central Queensland University

October - Library - Central Queensland University

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

16<br />

Metrics For<br />

Managing Maintenance<br />

T<br />

Raymond P. McFarland (USA)<br />

Recently published in the Reliability Magazine, Vol 10 Issue 3.<br />

This paper was originally presented at the 2003 SMRP conference.<br />

he Maintenance Manager is faced with the challenge of offsetting or moderating increased cost through better use of<br />

cost control techniques. The principal shortcoming in cost control methodologies is the absence of measurements that relate value<br />

received to maintenance dollars spent. There are two primary metric types, lead metrics and lag metrics. The lag metric the<br />

Maintenance Manager is most familiar with; perf o rmance to budget. But if the emphasis is placed on the lead metrics the lag metric<br />

will generally turn out as desired. The emphasis should be to improve the Maintenance Manager’s ability to measure value re c e i v e d ,<br />

and this paper provides some criteria that can be used to measure value received in maintenance activities.<br />

The maintenance metrics not only serve as the basis for evaluating benefits received, but they also serve as the measure of<br />

achievement towards goals. Each metric should have a target goal the Maintenance Manager is striving to achieve. The goals<br />

acts like the par rating for each hole on the golf course. They are goals that can be achieved with very good perf o rmance, but must<br />

be combined together to measure the total effectiveness of the maintenance operation. One metric by itself is not enough; they<br />

must be brought together to give the complete picture of the maintenance operation. At the end of this paper is a table of<br />

representative values for each of the 30 metrics presented.<br />

The following paragraphs provide the metrics that allow the Maintenance Manger to assess the effectiveness of the maintenance<br />

operation. The paragraphs describe the periodic charts and metrics pre p a red for the Maintenance Manager to allow a quick<br />

overview of the health of the Maintenance organization.<br />

Planning & Scheduling Metrics<br />

Unreported Man-hours<br />

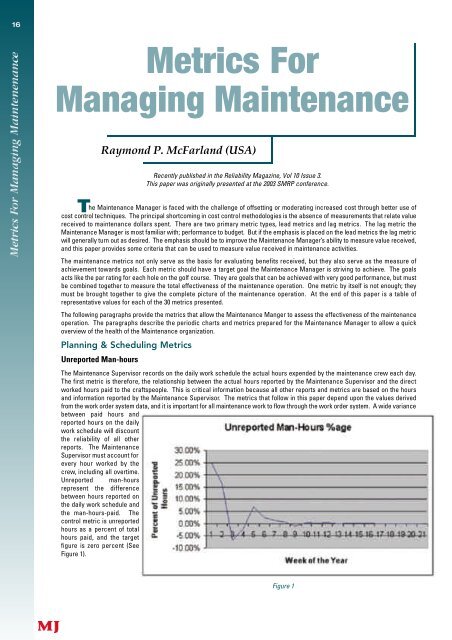

The Maintenance Supervisor records on the daily work schedule the actual hours expended by the maintenance crew each day.<br />

The first metric is there f o re, the relationship between the actual hours re p o rted by the Maintenance Supervisor and the dire c t<br />

worked hours paid to the craftspeople. This is critical information because all other reports and metrics are based on the hours<br />

and information re p o rted by the Maintenance Superv i s o r. The metrics that follow in this paper depend upon the values derived<br />

f rom the work order system data, and it is important for all maintenance work to flow through the work order system. A wide variance<br />

between paid hours and<br />

re p o rted hours on the daily<br />

work schedule will discount<br />

the reliability of all other<br />

re p o rts. The Maintenance<br />

Supervisor must account for<br />

e v e ry hour worked by the<br />

c re w, including all overt i m e .<br />

U n re p o rted man-hours<br />

re p resent the diff e re n c e<br />

between hours re p o rted on<br />

the daily work schedule and<br />

the man-hours-paid. The<br />

c o n t rol metric is unre p o rt e d<br />

hours as a percent of total<br />

hours paid, and the targ e t<br />

f i g u re is zero percent (See<br />

Figure 1).<br />

Figure 1