October - Library - Central Queensland University

October - Library - Central Queensland University

October - Library - Central Queensland University

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

8<br />

Maintenance In Iraq<br />

When it comes to asset care, a war zone and<br />

an industrial plant have much in common<br />

U<br />

Ricky Smith (USA)<br />

This article first appeared in Plant Services<br />

Magazine www.plantservices.com<br />

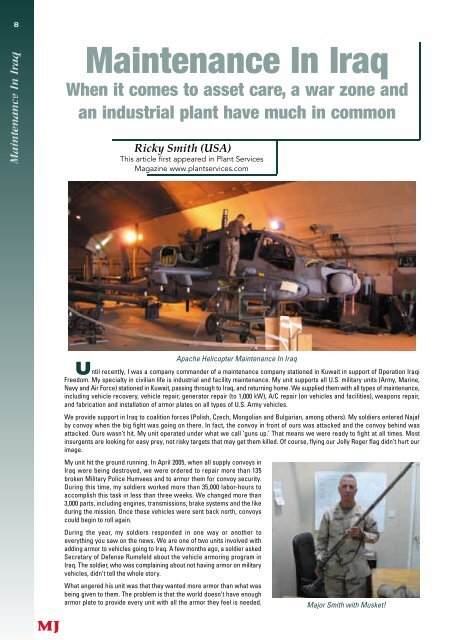

Apache Helicopter Maintenance In Iraq<br />

ntil recently, I was a company commander of a maintenance company stationed in Kuwait in support of Operation Iraqi<br />

Freedom. My specialty in civilian life is industrial and facility maintenance. My unit supports all U.S. military units (Army, Marine,<br />

Navy and Air Force) stationed in Kuwait, passing through to Iraq, and re t u rning home. We supplied them with all types of maintenance,<br />

including vehicle re c o v e ry, vehicle re p a i r, generator repair (to 1,000 kW), A/C repair (on vehicles and facilities), weapons re p a i r,<br />

and fabrication and installation of armor plates on all types of U.S. Army vehicles.<br />

We provide support in Iraq to coalition forces (Polish, Czech, Mongolian and Bulgarian, among others). My soldiers entered Najaf<br />

by convoy when the big fight was going on there. In fact, the convoy in front of ours was attacked and the convoy behind was<br />

attacked. Ours wasn’t hit. My unit operated under what we call ‘guns up.’ That means we were ready to fight at all times. Most<br />

insurgents are looking for easy prey, not risky targets that may get them killed. Of course, flying our Jolly Roger flag didn’t hurt our<br />

image.<br />

My unit hit the ground running. In April 2005, when all supply convoys in<br />

Iraq were being destroyed, we were ord e red to repair more than 135<br />

broken Military Police Humvees and to armor them for convoy security.<br />

During this time, my soldiers worked more than 35,000 labor-hours to<br />

accomplish this task in less than three weeks. We changed more than<br />

3,000 parts, including engines, transmissions, brake systems and the like<br />

during the mission. Once these vehicles were sent back north, convoys<br />

could begin to roll again.<br />

During the year, my soldiers responded in one way or another to<br />

everything you saw on the news. We are one of two units involved with<br />

adding armor to vehicles going to Iraq. A few months ago, a soldier asked<br />

S e c re t a ry of Defense Rumsfeld about the vehicle armoring program in<br />

Iraq. The soldier, who was complaining about not having armor on military<br />

vehicles, didn’t tell the whole story.<br />

What angered his unit was that they wanted more armor than what was<br />

being given to them. The problem is that the world doesn’t have enough<br />

armor plate to provide every unit with all the armor they feel is needed.<br />

Major Smith with Musket!